Catalyst for preparing cyclododecene through selective hydrogenation, preparation method and applications thereof

A kind of technology of cyclododecene and cyclododecatriene, applied in the catalyst and preparation field of selective hydrogenation to prepare cyclododecene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

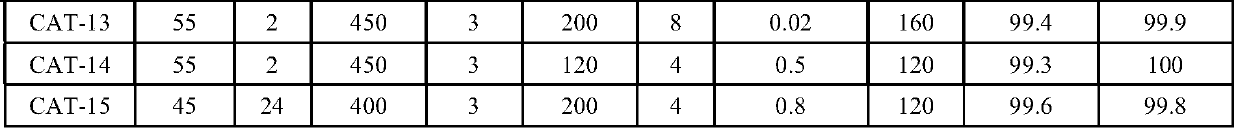

Examples

Embodiment 1

[0032] Dissolve 1g of rhodium trichloride (rhodium content is 0.50g) in 100mL of water, heat up to 100°C, add 90g of γ-alumina (10-30 mesh) into it, impregnate and adsorb the carrier for 0.5 hours, wash with pure water for 3 times, and set the temperature at 400°C Burning under the same conditions for 3 hours. Metal helper 0.45g bismuth nitrate (0.20g bismuth content) was dissolved in 100mL water, heated to 100°C, impregnated and adsorbed for 0.5 hour, washed with pure water 3 times, then burned at 400°C for 3 hours. Under hydrogen atmosphere, the catalyst CAT-01 (0.5%Rh-0.20%Bi / γ-alumina) was prepared by reducing at 100°C for 0.5 hours.

[0033] In a 500mL autoclave, add 1.0g of catalyst CAT-01, add 200g of cyclododecene, set the temperature of the reaction kettle at 120°C, feed hydrogen to maintain the pressure to 0.5MPa, and the reaction is over for 3 hours. The conversion rate was 99.9%, and the selectivity was 99.5%.

[0034] The procedure is the same as in Example 1, a...

Embodiment 2

[0043] Select 20g of CAT-15 catalyst, press it into tablets, then crush it, and use a 20-40 mesh screen. Select 10g and add it into a fixed-bed reactor with a pipe diameter of 10mm and a pipe length of 800mm. Control the reaction temperature to 110-120° C., and the back pressure of the reaction system to 0.02 MPa. Adjust the feeding amount of 1,5,9-cyclododecatriene to 0.36ml / min, and the hydrogen rate to 120ml / min. After continuous operation for 100 hours, the reaction materials were collected, and the reaction results were tested: the conversion rate was 99.8%, and the selectivity was 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com