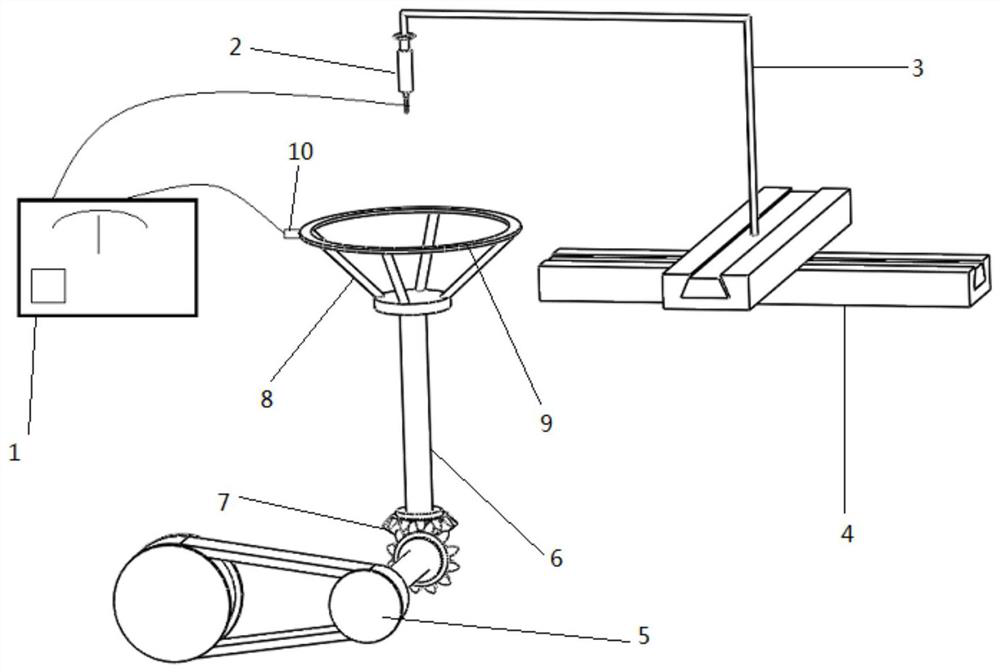

A device and method for preparing ultra-large area suspended nanofiber webs

A nanofiber mesh and super-large area technology, which is applied in the field of devices for preparing super-large-area suspended nanofiber meshes, can solve the problems of irregular deposition of fibers, clogging of injection ports, etc., and achieve the effects of weakening electric field strength, weakening influence, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Selection of electrospinning materials

[0035] The 200,000-grade PVA polyvinyl alcohol 1788 material used in this embodiment can also be selected from PVP polyvinylpyrrolidone and PAN polyacrylonitrile. This type of material has good resilience and curling properties, and excellent film-forming properties. The preferred PVA polyvinyl alcohol 1788 in the experiment of the present invention is because of its good solubility, it can be dissolved in the aqueous solution by heating at 65-75°C, and it is not easy to produce gel during spinning to block the spinning nozzle.

[0036] (2) Electrospinning fiber preparation

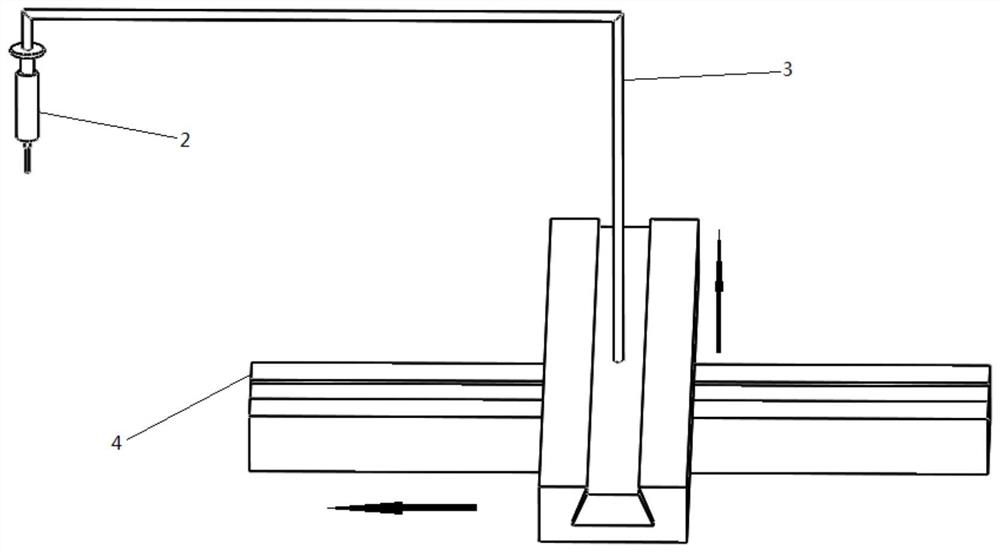

[0037] Weighed 6 g of PVA polyvinyl alcohol 1788 with a molecular weight of 200,000 grade and added it to 40 ml of deionized water to prepare a solution with a mass ratio of 15%. Stir in a water bath at 70°C until it is completely dissolved and prepare the spinning solution; add the completely dissolved PVA1788 solution to the needle-type spinning nozzl...

Embodiment 2

[0043] The experimental procedure is the same as in Example 1, and the specific parameters are as follows:

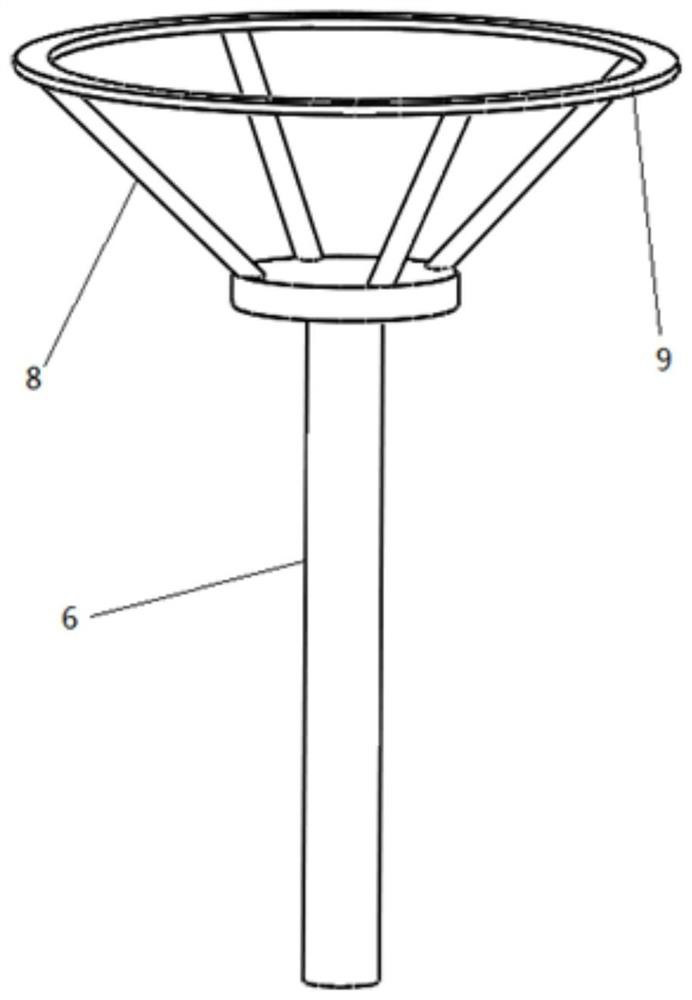

[0044] The spinning solution is a PVP polyvinylpyrrolidone solution with a concentration of 12% mass ratio; the voltage is 10KV; the distance between the needle tube type spinning nozzle 2 and the metal ring 9 is 20cm, the spinning speed is 1.2ml / h, and the air humidity is kept at 39% or less. It is also possible to obtain a super-large-area suspended nanofiber web.

Embodiment 3

[0046] The experimental procedure is the same as in Example 1, and the specific parameters are as follows:

[0047] The spinning solution is a PAN polyacrylonitrile solution with a concentration of 18% by mass; the voltage is 20KV; the distance between the needle tube type spinning nozzle 2 and the metal ring 9 is 30cm, the spinning speed is 2.5ml / h, and the air humidity is maintained at 39% or less. It is also possible to obtain a super-large-area suspended nanofiber web.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com