Temperature-change-resistant conveying belt and preparation method thereof

A conveyor belt and temperature-resistant technology, which is applied in the field of temperature-resistant variable conveyor belts and their preparation, can solve the problems of reduced wear resistance and poor temperature change resistance of conveyor belts, and achieves improved wear resistance and temperature change resistance. The effect of improved anti-aging performance and good reinforcing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

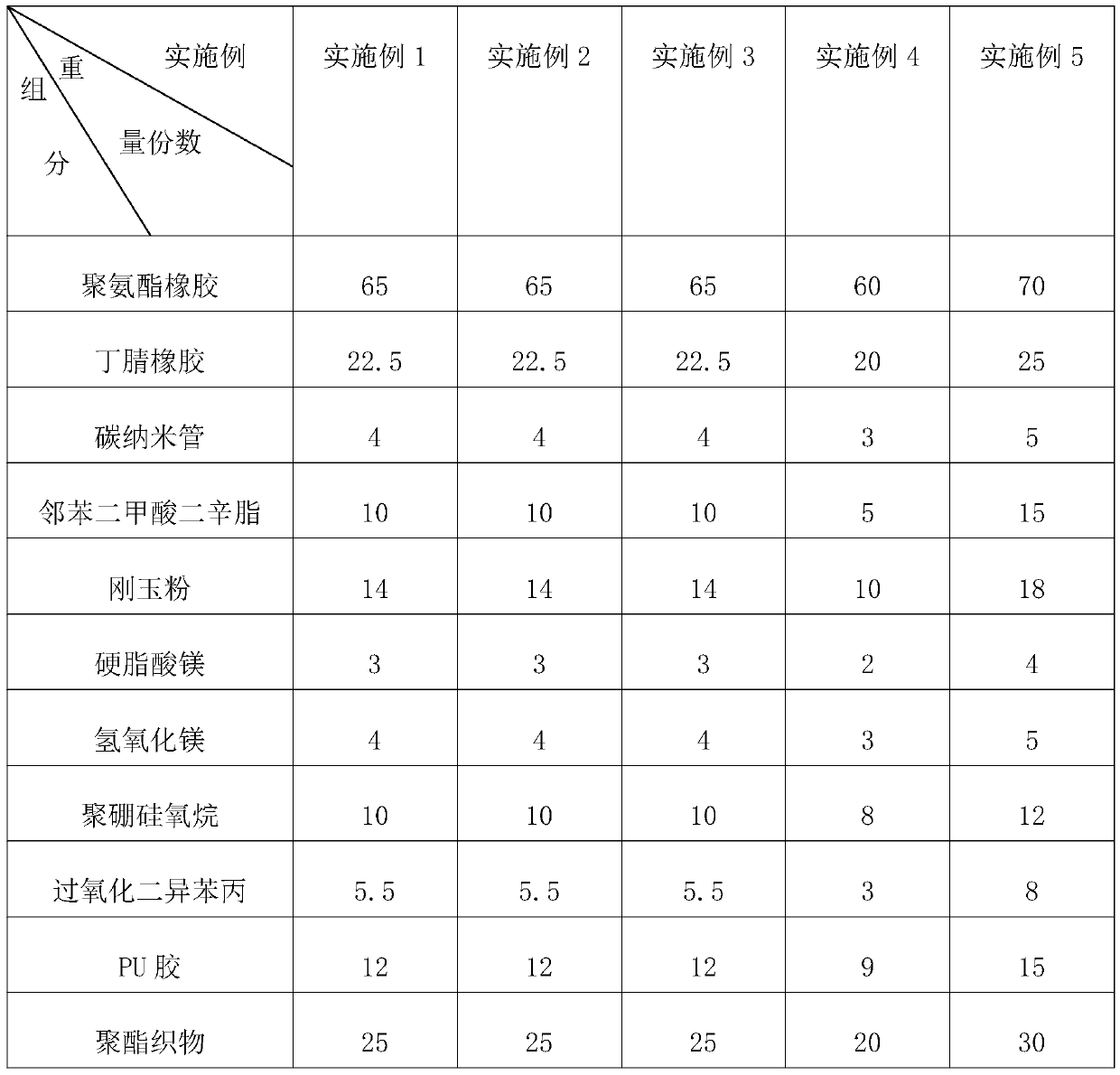

[0048] Embodiment 1: A kind of temperature-resistant modified conveyor belt, each component and its corresponding parts by weight are shown in Table 1, and it is prepared through the following steps:

[0049] Step 1, fabric drying: drying polyester fabrics of corresponding weight parts at a drying temperature of 160°C for 7.5 minutes, and storing them for later use;

[0050] Step 2, glue brushing and curing: then evenly scrape and coat the PU glue of the corresponding parts by weight on the front and back of the polyester fabric, and the brushing temperature is 160°C to form an adhesive layer;

[0051] Step 3, melt extrusion: polyurethane rubber, nitrile rubber, carbon nanotubes, dioctyl phthalate, corundum powder, magnesium stearate, magnesium hydroxide, polyborosiloxane and After the dicumyl peroxide is fully stirred and mixed, the stirring speed is 2000 rpm, the stirring time is 15 min, melt extrusion, the melt extrusion temperature is 165 ° C, and the screw extrusion speed...

Embodiment 2

[0054] Embodiment 2: A kind of temperature-resistant variant conveyor belt, the difference from Embodiment 1 is that it specifically includes the following steps:

[0055] Step 1, fabric drying: drying polyester fabrics of corresponding weight parts at a drying temperature of 150°C for 10 minutes, and storing them for later use;

[0056] Step 2, glue brushing and curing: then evenly scrape and coat the PU glue of the corresponding parts by weight on the front and back of the polyester fabric, and the brushing temperature is 150°C to form an adhesive layer;

[0057] Step 3, melt extrusion: polyurethane rubber, nitrile rubber, carbon nanotubes, dioctyl phthalate, corundum powder, magnesium stearate, magnesium hydroxide, polyborosiloxane and After dicumyl peroxide is fully stirred and mixed, the stirring speed is 1500 rpm, the stirring time is 20 min, melt extrusion, the melt extrusion temperature is 155 ° C, and the screw extrusion speed is 35 rpm to obtain a rubber layer;

[0...

Embodiment 3

[0059] Embodiment 3: A kind of temperature-resistant variant conveyor belt, which is different from Embodiment 1 in that it specifically includes the following steps:

[0060] Step 1, fabric drying: drying polyester fabrics of corresponding weight parts at a drying temperature of 170°C for 5 minutes, and storing them for later use;

[0061] Step 2, glue brushing and curing: then evenly scrape and coat the PU glue of the corresponding parts by weight on the front and back of the polyester fabric, and the brushing temperature is 170°C to form an adhesive layer;

[0062] Step 3, melt extrusion: polyurethane rubber, nitrile rubber, carbon nanotubes, dioctyl phthalate, corundum powder, magnesium stearate, magnesium hydroxide, polyborosiloxane and After the dicumyl peroxide is fully stirred and mixed, the stirring speed is 2500rpm, the stirring time is 10min, melt extrusion, the melt extrusion temperature is 175°C, and the screw extrusion speed is 25rpm to obtain a rubber layer;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com