Method for microwave extraction of asparagus agar

A technology of asparagus and asparagus, which is applied in the field of microwave extraction of asparagus agar, can solve the problems of difficult control of product quality, increased pressure of sewage treatment, complex and changeable molecular structure, etc., so as to alleviate the pressure of sewage treatment and reduce the Water consumption, the effect of reducing product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

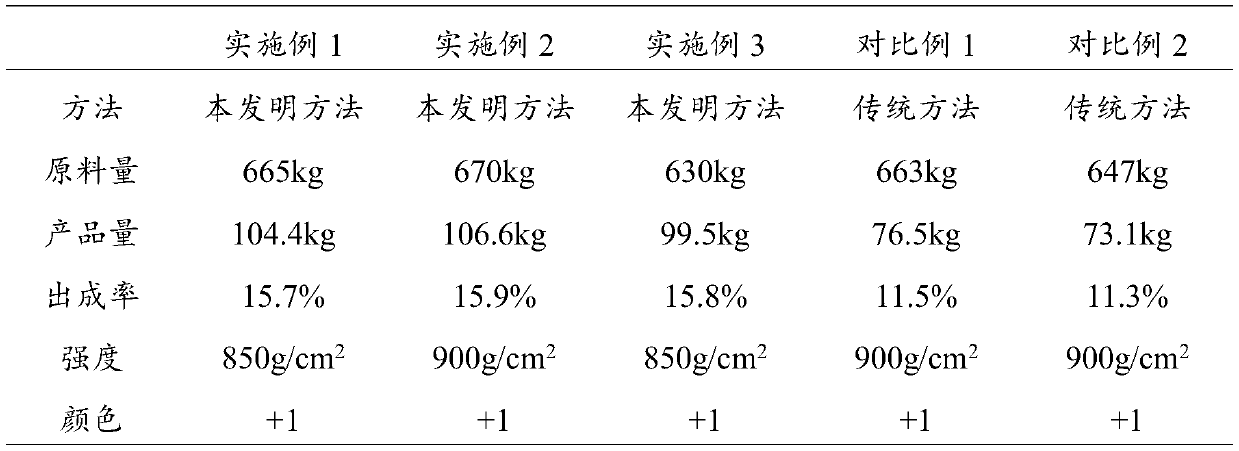

Embodiment 1

[0041] Embodiment 1 A kind of method of microwave extraction asparagus agar

[0042] 1) 665 kg of raw asparagus, washed and rinsed, cut into 5 cm sections to obtain asparagus sections;

[0043] 2) The asparagus segment was put into an aqueous sodium hydroxide solution with a mass percentage of 5% and a temperature of 90° C., with a microwave intensity of 600 W, and treated for 2 hours;

[0044] 3) Take out the asparagus, rinse with water until neutral;

[0045] 4) Rinse the asparagus, put it into 0.1% by mass bleaching water (sodium hypochlorite aqueous solution), stir and bleach for 15 minutes;

[0046] 5) Take out the asparagus, rinse with clean water;

[0047] 6) Put asparagus into an aqueous oxalic acid solution with a concentration of 0.15g / 100mL, and stir and acidify at 35rpm for 20min;

[0048] 7) Take out the asparagus and rinse with clean water;

[0049] 8) According to the ratio of 1g to 20mL of material and water, add the processed asparagus agar into a cooking ...

Embodiment 2

[0055] Embodiment 2 A kind of method of microwave extraction asparagus agar

[0056] 1) 670 kg of raw asparagus, washed and rinsed, cut into 4 cm sections to obtain asparagus sections;

[0057] 2) The asparagus segment was put into the sodium hydroxide aqueous solution with a mass percentage of 4% and a temperature of 92°C, and the microwave intensity was 800W, and treated for 2.5h;

[0058] 3) Take out the asparagus, rinse with water until neutral;

[0059] 4) Rinse the asparagus cleanly, put it into 0.1% by mass bleaching water (sodium hypochlorite aqueous solution), stir and bleach for 20 minutes;

[0060] 5) Take out the asparagus, rinse with clean water;

[0061] 6) Put asparagus into an aqueous oxalic acid solution with a concentration of 0.1g / 100mL, and stir and acidify at 35rpm for 20min;

[0062] 7) Take out the asparagus and rinse with clean water;

[0063] 8) According to the ratio of material to water ratio of 1g: 20mL, add the treated asparagus agar into a coo...

Embodiment 3

[0069] Embodiment 3 A kind of method of microwave extraction asparagus agar

[0070] 1) 630 kg of asparagus as a raw material, washed and rinsed, cut into 6 cm sections to obtain asparagus sections;

[0071] 2) The asparagus segment was put into the sodium hydroxide aqueous solution with a mass percentage of 3% and a temperature of 89°C, and the microwave intensity was 900W, and treated for 1.5h;

[0072] 3) Take out the asparagus, rinse with water until neutral;

[0073] 4) Rinse the asparagus cleanly, put it into 0.1% by mass bleaching water (sodium hypochlorite aqueous solution), stir and bleach for 20 minutes;

[0074] 5) Take out the asparagus, rinse with clean water;

[0075] 6) Put asparagus into an aqueous oxalic acid solution with a concentration of 0.1g / 100mL, and stir and acidify at 35rpm for 20min;

[0076] 7) Take out the asparagus and rinse with clean water;

[0077] 8) According to the ratio of material to water ratio of 1g: 20mL, add the treated asparagus a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com