Multi-layer on-line fitting type stone-plastic plate

A stone-plastic board and stone-plastic technology, applied in the direction of layered products, synthetic resin layered products, glass/slag layered products, etc., can solve the problem of large stress, increased stress of resin boards, affecting the mechanical properties and flatness of resin boards Degree and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

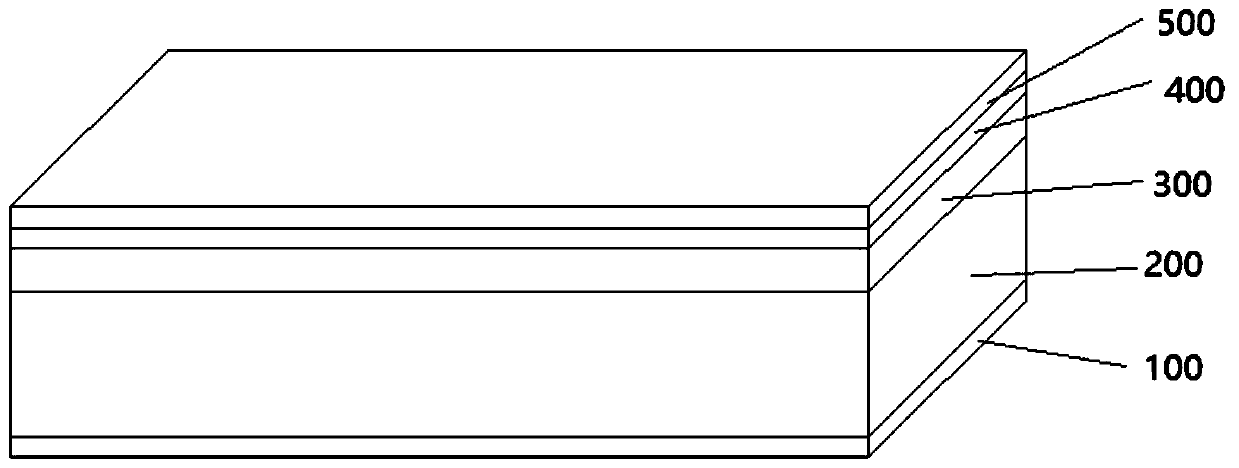

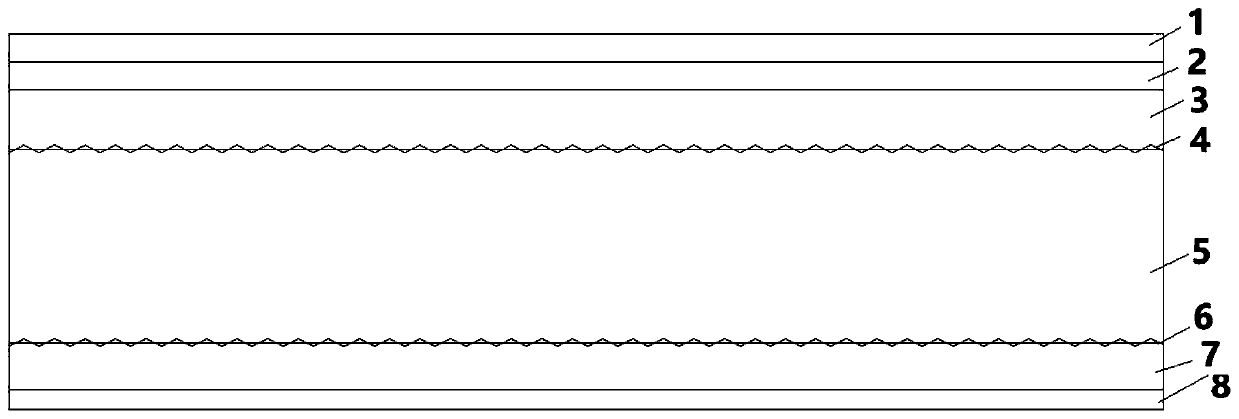

[0161] Such as image 3 As shown, the multi-layer online laminated stone plastic board includes wear-resistant layer 1, decorative layer 2, upper stone plastic layer 3, glass fiber cloth layer 4, middle stone plastic layer 5, and glass fiber cloth layer from the top layer to the bottom layer. 6. Lower stone plastic layer 7 and buffer layer 8, the upper stone plastic layer, middle stone plastic layer and lower stone plastic layer are extruded separately, the mesh size of glass fiber cloth is 2mm*2mm, and the wear-resistant layer is made of alumina Melamine formaldehyde resin, the decorative layer is a pre-printed PVC film, the thickness of the upper stone plastic layer is 1.5mm, and the thickness is higher than that of the upper stone plastic layer: middle stone plastic layer: lower stone plastic layer=1:3:0.9, and the buffer layer is 1mm Thickness of foamed PVC, foaming degree is 8.

[0162] The upper stone plastic layer is composed of the following raw materials in parts by weig...

Embodiment 2

[0169] This multi-layer online laminated stone plastic panel includes wear-resistant layer, decorative layer, upper stone plastic layer, glass fiber cloth layer, middle stone plastic layer, glass fiber cloth layer, lower stone plastic layer and buffer layer from top to bottom. , The upper stone plastic layer, middle stone plastic layer and lower stone plastic layer are separately extruded. The mesh size of the glass fiber cloth is 5mm*5mm. Double-layer glass fiber cloth can be used. The wear-resistant layer is polyurethane and the thickness of the upper stone plastic layer is 1mm, thickness ratio of upper stone plastic layer: middle stone plastic layer: lower stone plastic layer=1:4.5:1.5, and the buffer layer is XPE with a thickness of 1mm.

[0170] The upper stone plastic layer is composed of the following raw materials in parts by weight:

[0171]

[0172] The stone plastic layer is composed of the following raw materials in parts by weight:

[0173]

[0174] The lower stone plas...

Embodiment 3

[0177] This multi-layer online laminated stone-plastic board includes wear-resistant layer 1, decorative layer 2, upper stone plastic layer 3, glass fiber cloth layer 4, middle stone plastic layer 5, glass fiber cloth layer 6, and lower layer from top to bottom. The stone plastic layer 7 and the buffer layer 8, the upper stone plastic layer, the middle stone plastic layer and the lower stone plastic layer are extruded separately, the mesh size of the glass fiber cloth is 7mm*7mm, the wear-resistant layer is polyurethane, and the thickness of the upper stone plastic layer is 2mm, the thickness ratio of upper stone plastic layer: middle stone plastic layer: lower stone plastic layer=1:3.8:1, the buffer layer is 2mm thick IXPE.

[0178] The upper stone plastic layer is composed of the following raw materials in parts by weight:

[0179]

[0180] The stone plastic layer is composed of the following raw materials in parts by weight:

[0181]

[0182] The lower stone plastic layer is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com