Multilayer online laminating type stone-plastic plate production system

A production system and technology of stone-plastic panels, applied in the direction of layered products, synthetic resin layered products, glass/slag layered products, etc. degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

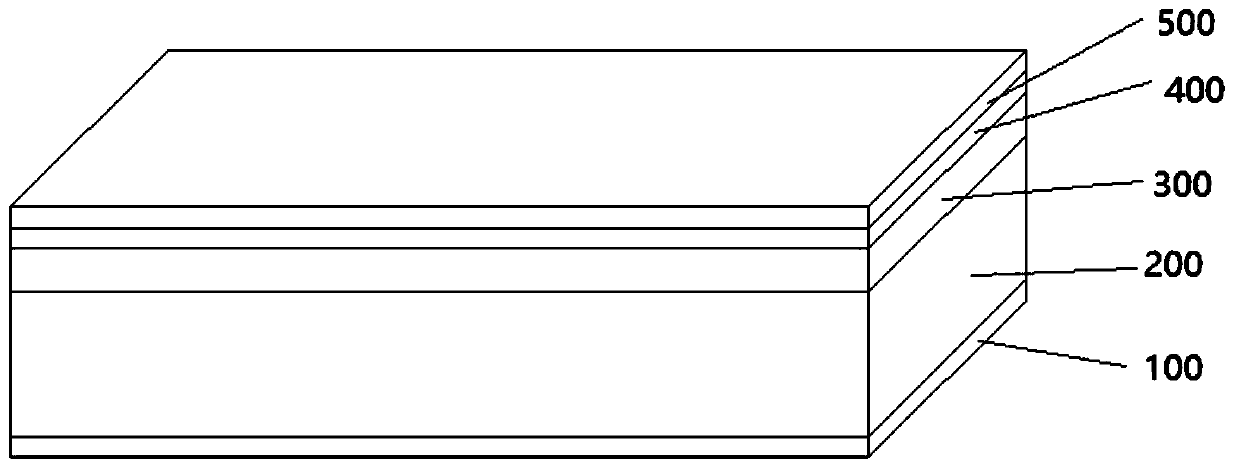

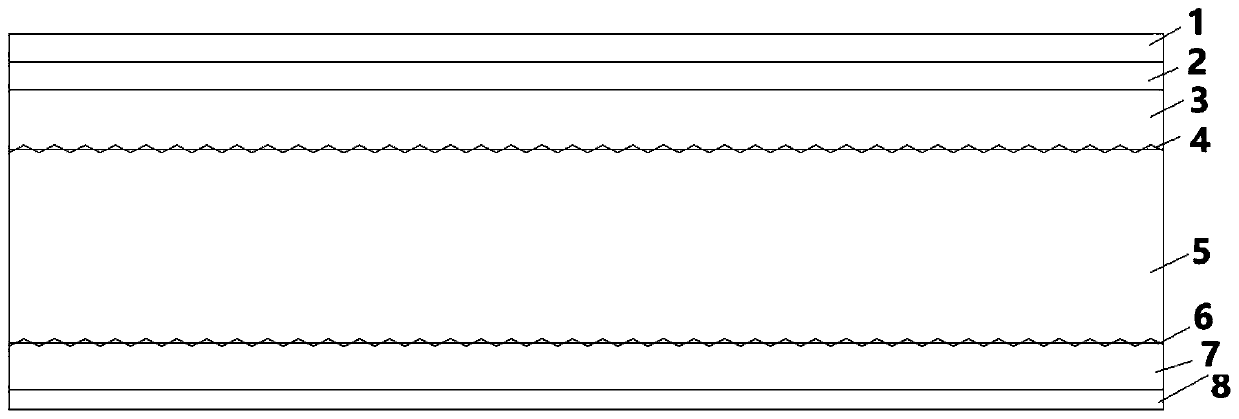

[0161] Such as image 3 As shown, the multi-layer online laminated stone-plastic panel includes wear-resistant layer 1, decorative layer 2, upper stone-plastic layer 3, glass fiber cloth layer 4, middle stone-plastic layer 5, and glass fiber cloth layer from the top layer to the bottom layer. 6. The lower stone-plastic layer 7 and the buffer layer 8, the upper stone-plastic layer, the middle stone-plastic layer and the lower stone-plastic layer are respectively extruded, the mesh size of the glass fiber cloth is 2mm*2mm, and the wear-resistant layer is made of aluminum oxide Melamine formaldehyde resin, the decorative layer is a PVC film with pre-printed patterns, the thickness of the upper stone-plastic layer is 1.5mm, and the thickness is higher than the upper stone-plastic layer: middle stone-plastic layer: lower stone-plastic layer = 1:3:0.9, and the buffer layer is 1mm Thickness foamed PVC with a foaming degree of 8.

[0162] The upper stone-plastic layer consists of the...

Embodiment 2

[0169] This multi-layer online laminated stone-plastic panel includes wear-resistant layer, decorative layer, upper stone-plastic layer, glass fiber cloth layer, middle stone-plastic layer, glass fiber cloth layer, lower stone-plastic layer and buffer layer from the top layer to the bottom layer. , the upper stone-plastic layer, the middle stone-plastic layer and the lower stone-plastic layer are extruded separately, the mesh size of the glass fiber cloth is 5mm*5mm, double-layer glass fiber cloth can be used, the wear-resistant layer is polyurethane, and the thickness of the upper stone-plastic layer is 1mm, the thickness ratio of upper stone-plastic layer: middle stone-plastic layer: lower stone-plastic layer = 1:4.5:1.5, and the buffer layer is XPE with a thickness of 1mm.

[0170] The upper stone-plastic layer consists of the following raw materials in parts by weight:

[0171]

[0172] The Zhongshi plastic layer is composed of the following raw materials by weight:

...

Embodiment 3

[0177] This multi-layer online laminated stone-plastic panel includes wear-resistant layer 1, decorative layer 2, upper stone-plastic layer 3, glass fiber cloth layer 4, middle stone-plastic layer 5, glass fiber cloth layer 6, and lower layer from the top layer to the bottom layer. The stone-plastic layer 7 and the buffer layer 8, the upper stone-plastic layer, the middle stone-plastic layer and the lower stone-plastic layer are respectively extruded, the mesh size of the glass fiber cloth is 7mm*7mm, the wear-resistant layer is polyurethane, and the thickness of the upper stone-plastic layer is 2mm, the thickness ratio of upper stone-plastic layer: middle stone-plastic layer: lower stone-plastic layer = 1:3.8:1, and the buffer layer is IXPE with a thickness of 2mm.

[0178] The upper stone-plastic layer consists of the following raw materials in parts by weight:

[0179]

[0180] The Zhongshi plastic layer is composed of the following raw materials by weight:

[0181] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com