A spray-on plastic release agent

A mold release agent and plastic technology, applied in the field of spray-on plastic mold release agent, can solve the problems that affect the product appearance, mold service life, cracks and wrinkles, environmental pollution, etc., and achieve the improvement of product color, convenient demoulding, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

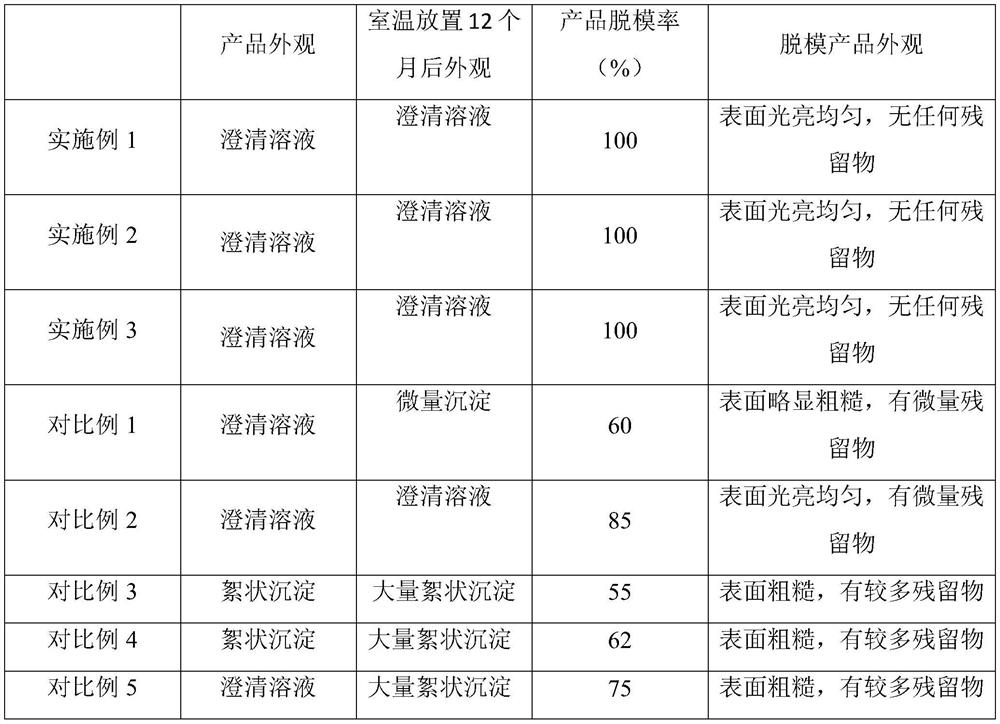

Examples

Embodiment 1

[0013] A spray-on plastic mold release agent is composed of A solution, B solution, C solution and D solution, wherein the volume ratio of A, B, C and D is 15:1.6:0.5:0.8.

[0014] Wherein, the A solution is prepared by the following method: 100ml of ethyl acetate, 15ml of eucalyptus oil and 3ml of glycerol carbonate are mixed.

[0015] The B solution was prepared by the following method: 100 mL of ethyl acetate and 15 mL of eucalyptus oil were mixed.

[0016] The C solution was prepared by the following method: dissolve 10 mL of simethicone in 100 mL of ethyl acetate and mix well.

[0017] The D solution was prepared by the following method: a mixed surfactant solution prepared by dissolving 10 g of sodium stearate and 10 g of Tween-80 in 100 mL of water.

[0018] Mix the above-mentioned A solution, B solution, C solution and D solution according to the volume ratio. The appearance of the product of the present invention is a clear solution.

Embodiment 2

[0020] A spray-on plastic mold release agent is composed of A solution, B solution, C solution and D solution, wherein the volume ratio of A, B, C and D is 25:1.6:0.5:0.9.

[0021] Wherein, the A solution is prepared by the following method: 100ml of ethyl acetate, 15ml of eucalyptus oil and 3ml of glycerol carbonate are mixed.

[0022] The B solution was prepared by the following method: 100 mL of ethyl acetate and 15 mL of eucalyptus oil were mixed.

[0023] The C solution was prepared by the following method: dissolve 10 mL of simethicone in 100 mL of ethyl acetate and mix well.

[0024] The D solution was prepared by the following method: a mixed surfactant solution prepared by dissolving 10 g of sodium stearate and 10 g of Tween-80 in 100 mL of water.

[0025] Mix the above-mentioned A solution, B solution, C solution and D solution according to the volume ratio. The appearance of the product of the present invention is a clear solution.

Embodiment 3

[0027] A spray-on plastic mold release agent is composed of A solution, B solution, C solution and D solution, wherein the volume ratio of A, B, C and D is 35:1.6:0.5:1.

[0028] Wherein, the A solution is prepared by the following method: 100ml of ethyl acetate, 15ml of eucalyptus oil and 3ml of glycerol carbonate are mixed.

[0029] The B solution was prepared by the following method: 100 mL of ethyl acetate and 15 mL of eucalyptus oil were mixed.

[0030] The C solution was prepared by the following method: dissolve 10 mL of simethicone in 100 mL of ethyl acetate and mix well.

[0031] The D solution was prepared by the following method: a mixed surfactant solution prepared by dissolving 10 g of sodium stearate and 10 g of Tween-80 in 100 mL of water.

[0032] Mix the above-mentioned A solution, B solution, C solution and D solution according to the volume ratio. The appearance of the product of the present invention is a clear solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com