A kind of catalytic cloth with the function of catalytic degradation of ethylene and its preparation and application

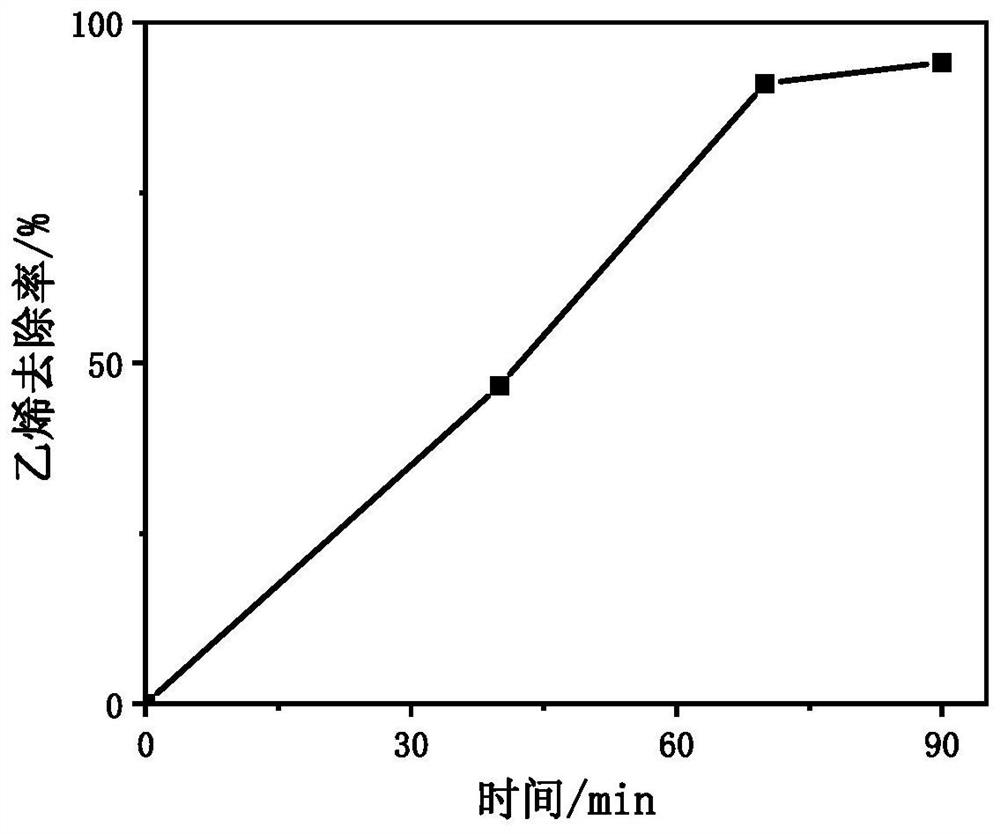

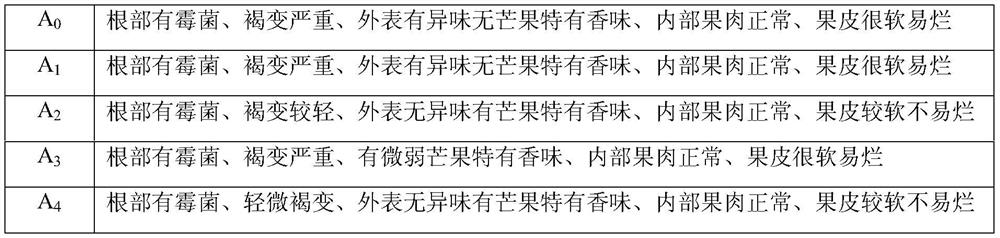

A technology of catalytic degradation and catalytic cloth, which is applied in catalytic reaction, application, organic compound/hydride/coordination complex catalyst, etc. Insufficient effect and other problems, to achieve the effect of low requirements for catalytic conditions, prolonging fresh-keeping period, and preventing microbial spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh 3.0kg of potassium permanganate, 3.0kg of ferric chloride, 2.0kg of cobalt chloride, and 4.0kg of ammonium oxalate into the reactor, and add 100L of distilled water into the reactor, stir and mix until uniform. Heat and stir in water at 100°C for 9 hours, and cool to room temperature naturally after the reaction. Soak and stir the modified material in pure water for 30 minutes. After the material slowly settles, pour off the water in the upper layer. Repeat the operation 3 times until the water after washing has no color. Put the cleaned material into an oven for drying at 70° C. to obtain a powdered catalyst.

[0039] (2) According to the mass ratio of catalyst: water: silica sol 1:2:2, add the catalyst into pure water, sonicate for 20 minutes, then add silica sol into the solution, stir for 10 minutes, and fully disperse to obtain the glue.

[0040] (3) Spray the glue solution prepared above to the positive and negative sides of the PET non-woven fabric to ...

Embodiment 2

[0047] (1) Weigh 1.6kg of sodium permanganate, 5.6kg of potassium ferrate, 1.6kg of cobalt nitrate, and 5.6kg of potassium oxalate in a reaction kettle, and add 20L of distilled water into the reaction kettle, stir and mix until uniform. Heat and stir in water at 70°C for 14 hours, and cool to room temperature naturally after the reaction. Soak and stir the reacted modified material in pure water for 10 minutes. After the material slowly settles, pour out the upper layer of water. Repeat the operation 5 times until the water after washing has no color. Put the cleaned material into an oven and dry it at 100° C. to obtain a powder catalyst.

[0048] (2) According to the catalyst:water:silica sol ratio of 1:0.5:1, add the catalyst into pure water, sonicate for 5 minutes, then add silica sol into the solution, stir for 3 minutes, and fully disperse to obtain the glue.

[0049] (3) Spray the glue solution prepared above onto the positive and negative sides of the nylon mesh to fo...

Embodiment 3

[0055] (1) Weigh 5.6kg of potassium permanganate, 1.6kg of ferric sulfate, 5.6kg of cobalt chloride, and 1.6kg of sodium oxalate in a reaction kettle, and add 50L of distilled water into the reaction kettle, stir and mix until evenly mixed. Heated and stirred in water at 120°C for 7 hours, and naturally cooled to room temperature after the reaction. Soak and stir the modified material in pure water for 20 minutes. After the material settles slowly, pour off the water in the upper layer. Repeat the operation 4 times until the water after washing has no color. The cleaned material was dried in an oven at 150° C. to obtain a powder catalyst.

[0056] (2) According to the catalyst:water:silica sol ratio of 1:3:4, add the catalyst into pure water, sonicate for 30 minutes, then add silica sol into the solution, stir for 20 minutes, and fully disperse to obtain the glue.

[0057] (3) The above-mentioned prepared glue is sprayed onto the positive and negative sides of the polyurethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com