Flow guide device, gas mixing equipment and gas treatment system

A technology of diversion device and gas mixing, applied in gas treatment, fluid mixer, mixer and other directions, can solve the problem of uneven distribution of flue gas flow field, achieve convenient assembly and maintenance, high integration, and improve the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

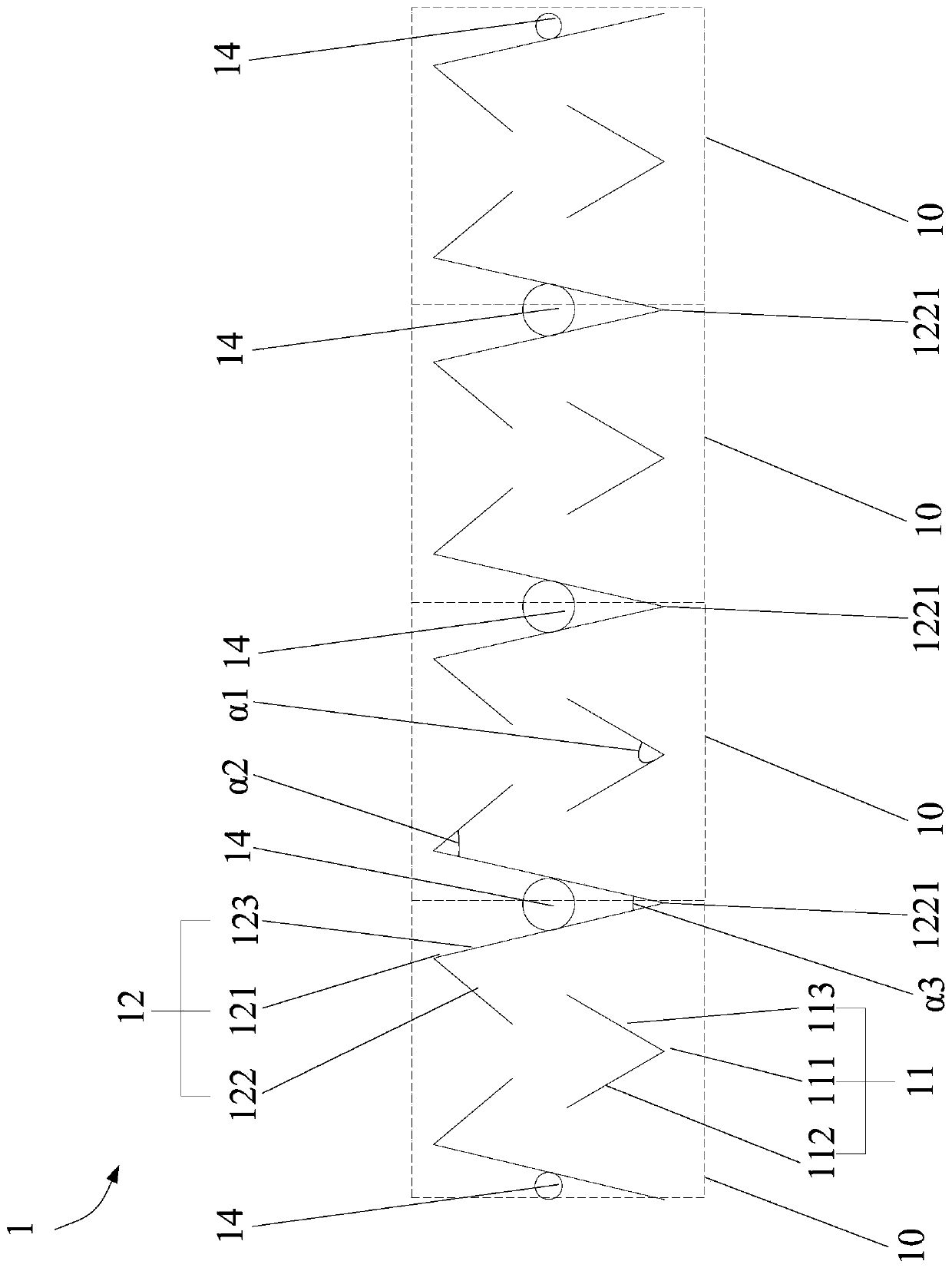

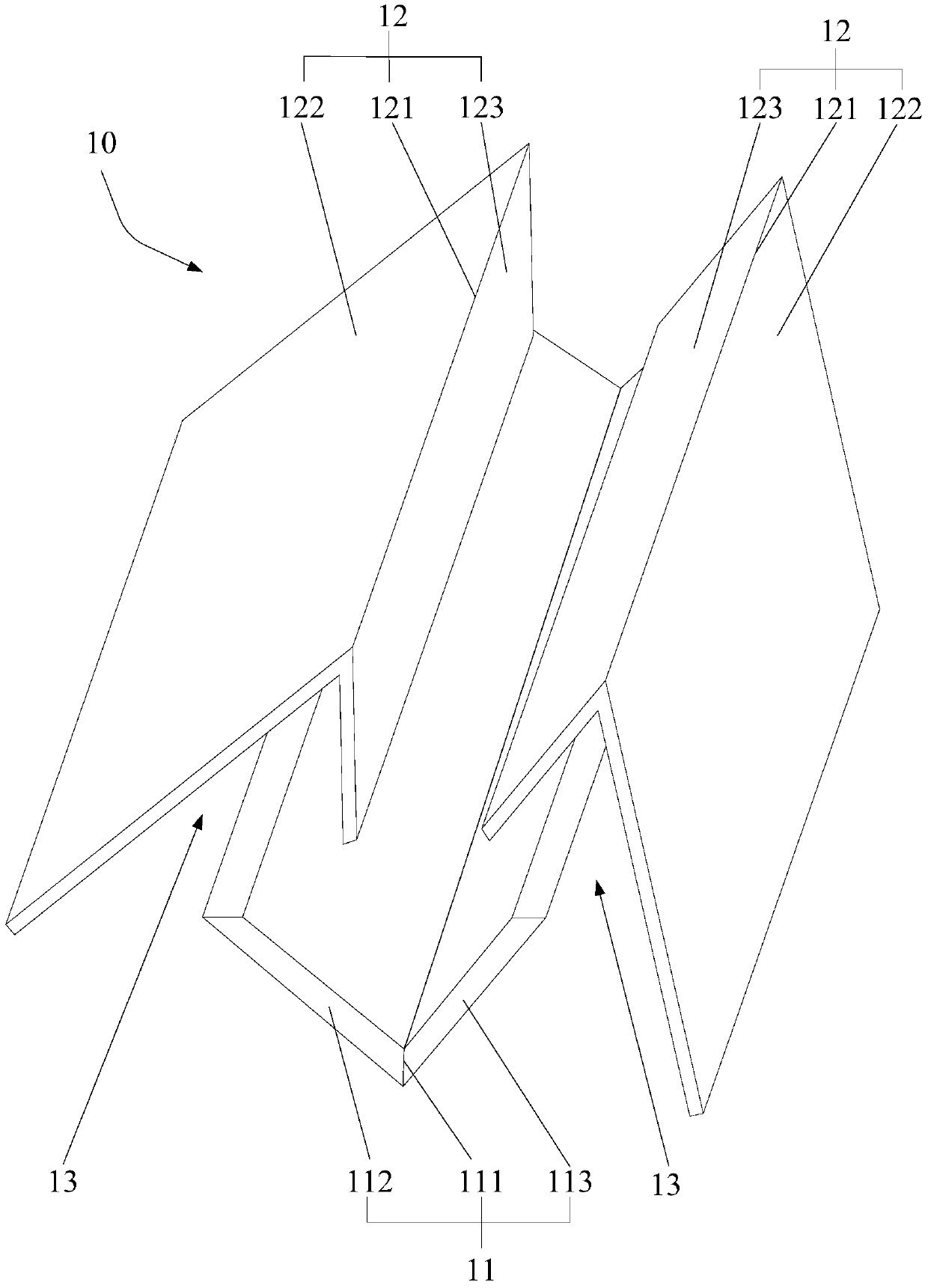

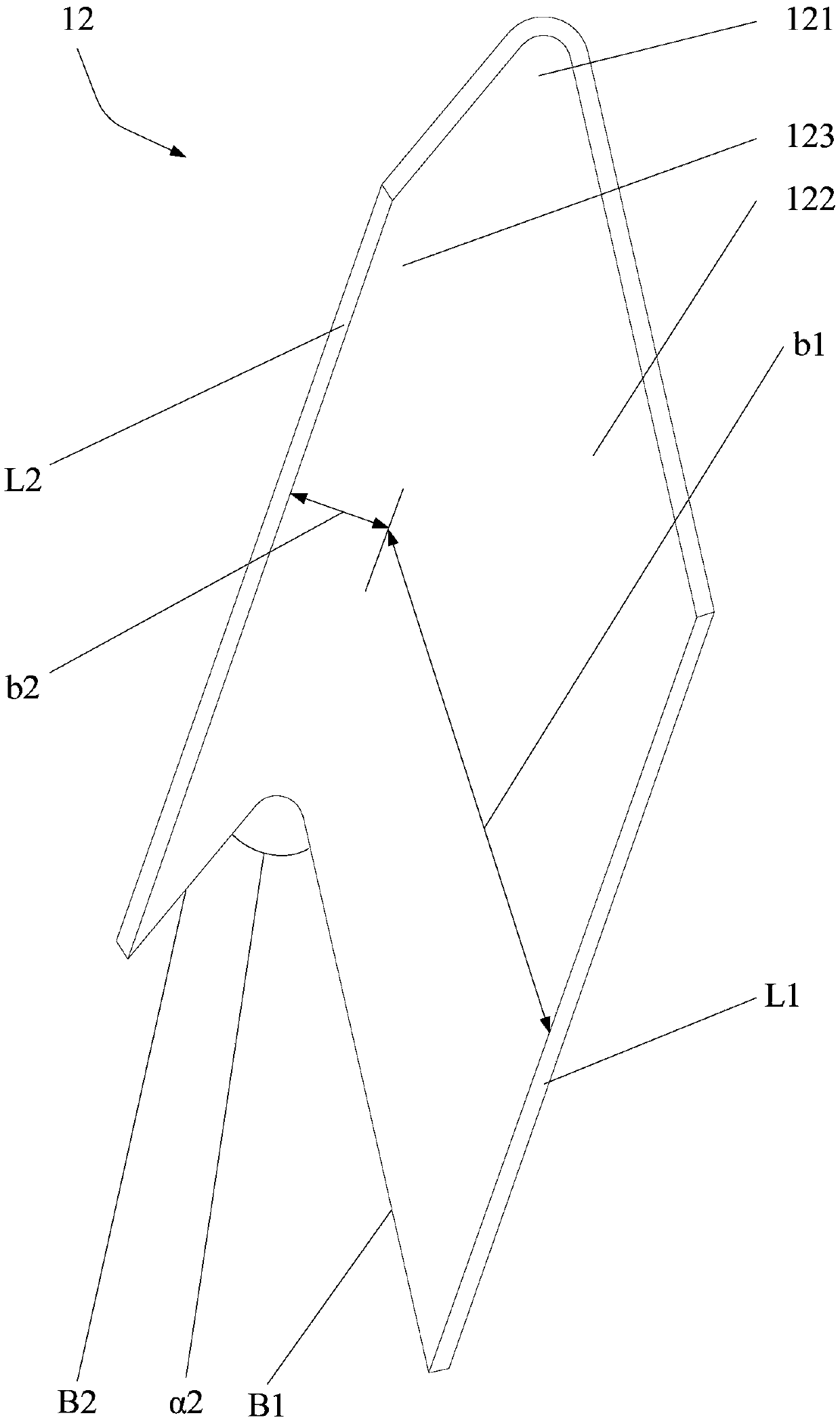

[0040] The present invention provides a flow guiding device 1, please refer to Figure 1 to Figure 6 , the flow guide device 1 includes a plurality of flow guide structures 10 arranged side by side, the flow guide structure 10 has a first flow guide piece 11 and two second flow guide pieces 12 symmetrically arranged on both sides of the first flow guide piece 11 , A gap 13 for fluid flow is formed between the first flow guide 11 and the second flow guide 12; wherein, the first flow guide 11 has a first bending portion 111, and the second flow guide 12 has a second In the bending portion 121 , the opening of the first bending portion 111 is disposed toward the opening of the second bending portion 121 .

[0041] The flow guide device 1 divides, guides and merges the fluid through the first flow guide 11 and the second flow guide 12, so that the fluid collides and disturbs during the movement, thereby forming a turbulent flow effect, and finally making the flow The gas passing ...

Embodiment approach 2

[0061] Such as Figure 1 to Figure 7 As shown, the present invention provides a gas mixing device 2, which includes a flow guiding device 1 and a gas delivery mechanism 21, and the gas delivery mechanism 21 has a plurality of gas injection parts 211 arranged at intervals. Wherein, the flow guiding device 1 is disposed on the same side of the plurality of gas injection parts 211 , and the gas injection parts 211 are disposed opposite to the first bending part 111 . The specific structure, working principle and beneficial effects of the flow guiding device 1 in this embodiment are the same as those in the first embodiment, and will not be repeated here.

[0062] In the gas mixing device 2 provided by the present invention, the gas injection part 211 is arranged opposite to the first bending part 111, and then the gas injection part 211 is used to inject gas onto the first flow guide member 11 of the flow guide structure 10 in the flow guide device 1 , so that the first bending ...

Embodiment approach 3

[0068] Such as Figure 1 to Figure 8 As shown, the present invention provides a gas treatment system 3 .

[0069] Specifically, the gas processing system 3 includes a gas channel 31 and a gas mixing device 2, and the gas mixing device 2 is arranged in the gas channel 31; wherein, after the first gas enters the gas channel 31 along the fluid flow direction F, it can be combined with a plurality of gases The second gas ejected from the ejection part 211 is uniformly mixed through the flow guiding device 1 . The specific structure, working principle and beneficial effects of the gas mixing device 2 in this embodiment are the same as those in Embodiment 2, and will not be repeated here.

[0070] In a specific application environment, the gas channel 31 is a flue, the gas delivery mechanism 21 is an ammonia gas pipeline, the gas injection part 211 is a nozzle, the first gas is flue gas, and the second gas is ammonia gas. The working principle and working process of the gas treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com