Multidirectional mixing type cement homogenization equipment

A kind of homogenization equipment and mixing technology, which is applied in the direction of mixers, mixers with rotating containers, shaking/oscillating/vibrating mixers, etc. It can solve the problems of poor homogenization of suspended powder and achieve excellent homogenization effect, Convenient production, ingenious and practical mechanism design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

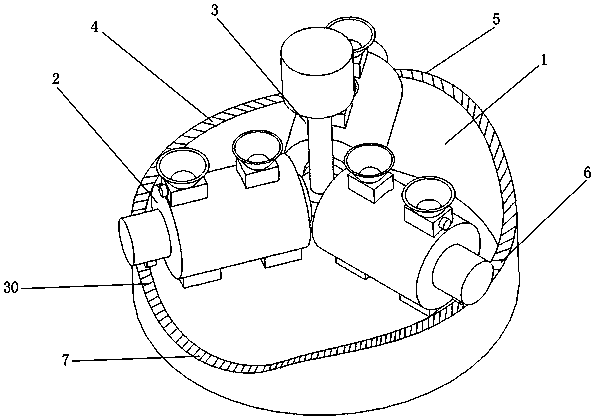

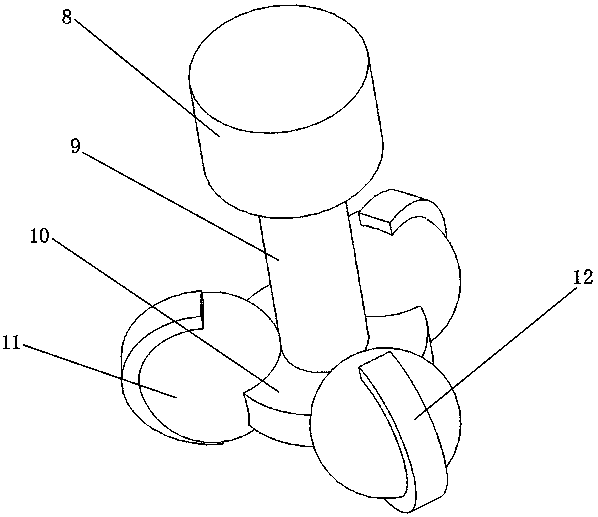

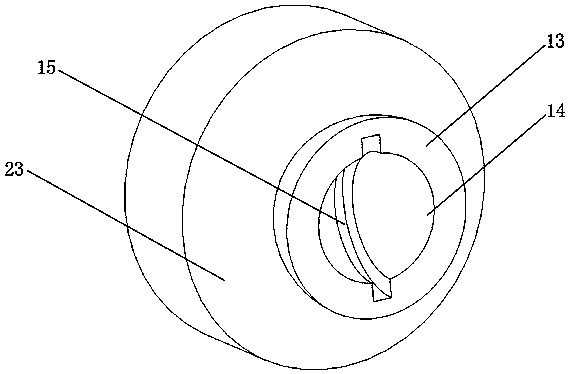

[0028] A multi-directional mixing type cement homogenization equipment, comprising a support ring seat 1, a three-connected homogenizer 2, a power connection device 3 and a control system; the support ring seat 1 is an annular base, and is provided with a high seat 5, two There is a flat seat 6 and a low seat 7; the high seat 5 is inclined upward to form a slope; the flat seat 6 is horizontal; the low seat 7 is sunken downward to form a groove; the adjacent high seat 5, flat The seat 6 and the two low seats 7 are arranged on the support ring seat 1 in a 90° ring; the high seat 5, the flat seat 6 and the low seat 7 are smoothly connected; on the upper surface of the support ring seat 1 A sunken ring rail 4 is provided; track teeth 30 are arranged on the ring rail 4; the three-connected homogenizer 2 is a three-group powder homogenization device; the end of the three-connected homogenizer 2 is arranged on On the ring track 4, the tail is set at the center of the support ring sea...

Embodiment 2

[0034] The structure and principle of this embodiment 2 are basically the same as that of the embodiment 1, except that the three-connected homogenizer also includes a feed connection port 32; the feed connection port 32 is arranged at the lower end of the feed port 18; The spray barrel 20 corresponds to the feeding connection port 32 . When the spray barrel 20 was turned to the position corresponding to the feed connection port 32, the top of the spray barrel 20 and the feed connection port 32 were all opened, and the unmixed powder was fed from the feed Port 18 falls into the spray barrel; after feeding is completed, the spray barrel 20 and the feed connection port 32 are all closed.

Embodiment 3

[0036] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, the difference is that the telescopic trachea device also includes an inner tube 34; the inner tube 34 is sleeved in the outer tube 33; The end is bent; the position switch avoidance cavity 35 is set on the bending part of the inner tube 34; the position switch 37 protrudes toward the inner wall of the inner tube 34; the sealing rubber pad 38 is set on the inner wall of the inner tube 34 and Located behind the position switch 37; the outer diameter of the air pipe 39 is smaller than the inner diameter of the inner pipe 34. When the roller 17 turns to a certain angle, the inner pipe 34 protrudes from the outer pipe 33; the air pipe 39 is inserted into the inner pipe 34, and the position switch 37 is pushed into the position switch avoidance cavity 35 to trigger the The air pump 19 is turned on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com