Loop type gas hydrate reaction device and reaction method

A gas hydrate and reaction device technology, which is applied in chemical methods, chemical instruments and methods, and chemical/physical processes for reacting liquids and gaseous media, and can solve the problems of hydrate slurry formation and transport conditions that cannot be observed in time , to achieve good mixing, increase reaction rate, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The hydrate reaction device of the present invention will be further described below in conjunction with the accompanying drawings, but this does not constitute a limitation of the present invention.

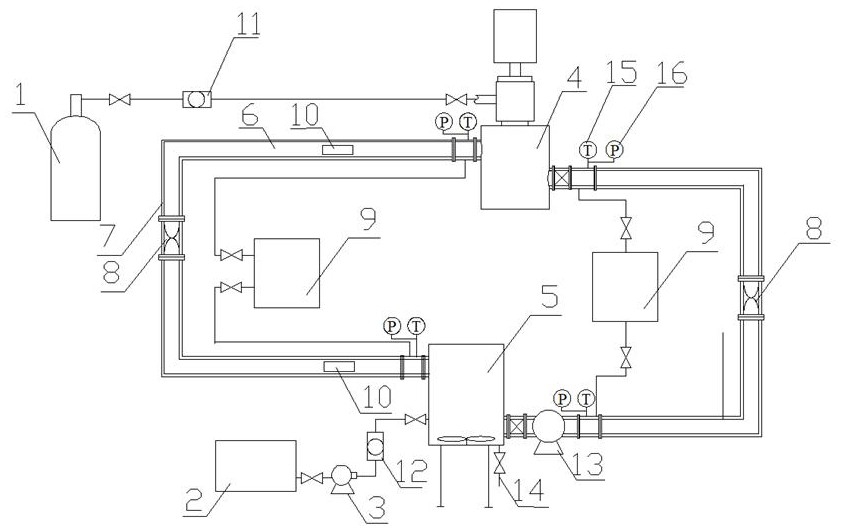

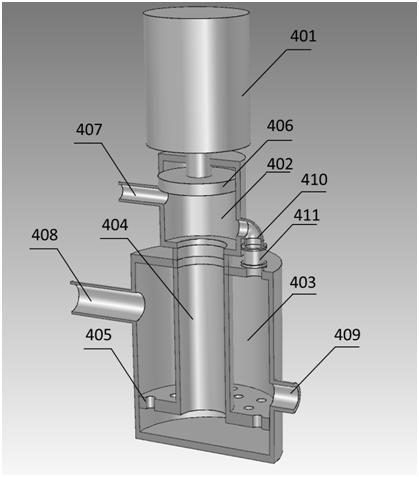

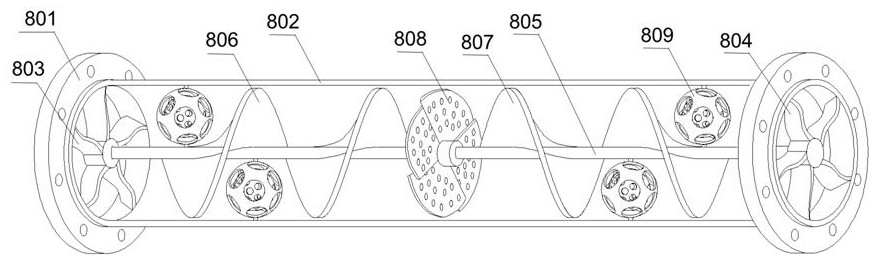

[0049] like figure 1 As shown, the present invention provides a loop-type gas hydrate reaction device, which mainly includes a gas source 1, a water source 2, a water pump 3, a microbubble gas injection unit 4, a buffer tank 5, and a loop 6. With cooling device 7, static mixer 8, temperature controller 9, visible window 10, gas flow meter 11, liquid flow meter 12, circulation pump 13, sampling port 14, temperature sensor 15, pressure sensor 16. . Microbubble type gas injection unit 4 comprises gas injection chamber 402, gas column sum 404 and bubble generation chamber 403; Bubble generation chamber 403 is set on the outside of gas column 404, and gas injection chamber 402 is directly communicated with gas column 404, and gas injection chamber 402 and The bubble generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com