Pipeline mixer

A pipeline mixer and mixed flow technology, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of increasing equipment costs, etc., and achieve the effect of improving blending, intensifying mixing degree, and enhancing mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The pipeline mixer of the present invention will be further described below in conjunction with the accompanying drawings, and the following examples are used to illustrate the present invention, but do not constitute a limitation of the present invention.

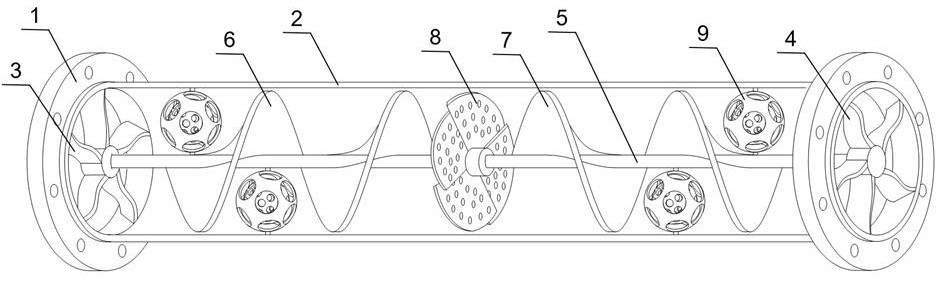

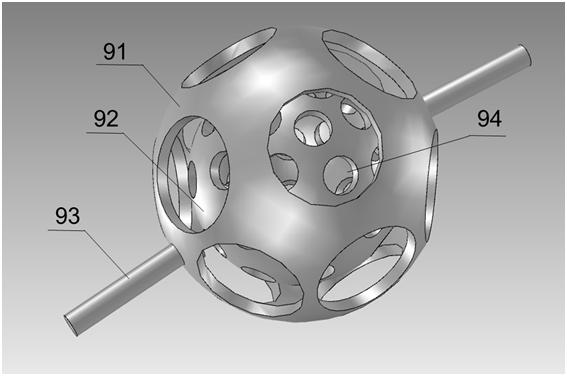

[0030] Such as Figure 1 to Figure 2 As shown, a pipeline mixer of the present invention mainly includes a flange 1, a pipe body 2, a right-handed blade 3, a left-handed blade 4, a central shaft 5, a left-handed helical impeller 6, a right-handed helical impeller 7, a porous shearing impeller 8, Double-layer hollow ball9. A pair of flanges 1 are provided at both ends of the pipe body 2, and the pipeline mixer is connected to the pipeline through the flanges 1; the flanges 1 at both ends are fixed and connected through the central shaft 5; the right-handed blade 3 is fixed inside the flange 1 at one end, and is connected with the right On the central axis 5 where the rotating blades 3 are coaxially connected, a left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com