Manufacturing method of ultraviolet light-emitting diode epitaxial structure layer

A technology of light-emitting diodes and epitaxial structures, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems such as the decline of the crystal quality of the epitaxial layer and the decline of the electrical conductivity, so as to simplify the design of the epitaxial structure, reduce the difficulty of preparation, and improve the overall light extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

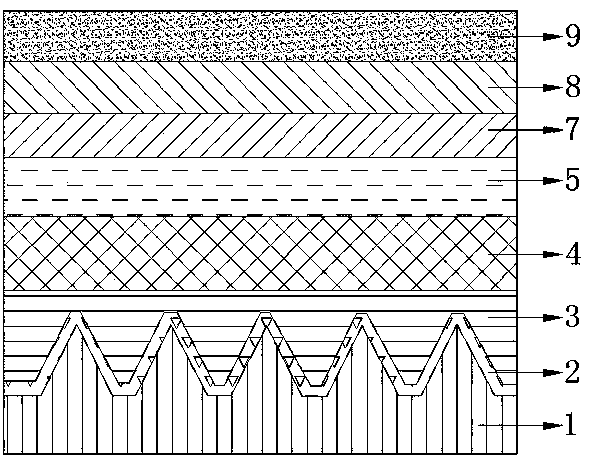

[0042] Embodiment 1, as figure 1 As shown, a method for preparing an epitaxial structure layer of an ultraviolet light-emitting diode includes a method for preparing an n-type doped AlN layer 4 by means of magnetron reactive sputtering, including the following steps:

[0043] Step S11, AlN buffer layer 2 sputtering:

[0044] S1101, the sapphire PSS sheet is introduced into the sputtering chamber, heated for 180 seconds, 120sccm nitrogen gas and 0.5sccm oxygen gas are introduced, the radio frequency power is 60W, and the radio frequency power is 90s;

[0045] S1102, 90sccm of nitrogen gas, 2sccm of oxygen gas, and 40sccm of argon gas are introduced into the sputtering chamber, the DC pulse sputtering power is set to 5000W, and the thickness of aluminum nitride with high oxygen content is deposited by sputtering to 10nm;

[0046] S1103. Inject 120 sccm of nitrogen gas into the sputtering chamber, set the RF power to 60W, and set the RF on time to 45s;

[0047] S1104, 90 sccm o...

Embodiment 2

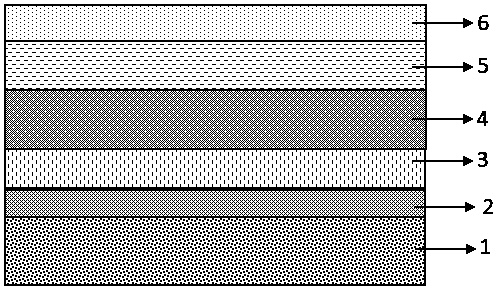

[0062] Embodiment 2, as figure 2 As shown, a method for preparing an epitaxial structure layer of an ultraviolet light-emitting diode includes a preparation method for realizing an n-type doped AlN layer 4 by magnetron reactive sputtering and a method for realizing a p-type doped AlN layer 6 by magnetron reactive sputtering. The preparation method comprises the following steps:

[0063] Step S1, AlN buffer layer 2 sputtering:

[0064] S1101, the sapphire flat sheet is introduced into the sputtering chamber, heated for 180 seconds, 120sccm nitrogen gas and 0.5sccm oxygen gas are introduced, the radio frequency power is 60W, and the radio frequency power is 90s;

[0065] S1102, 90sccm of nitrogen gas, 2sccm of oxygen gas, and 40sccm of argon gas are introduced into the sputtering chamber, the DC pulse sputtering power is set to 5000W, and the thickness of aluminum nitride with high oxygen content is deposited by sputtering to 10nm;

[0066] S1103. Inject 120 sccm of nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com