Electric control power device with real-time controllable thrust and capable of repeatedly igniting and extinguishing

A technology of repeated ignition and power devices, which is applied in the direction of rocket motor devices, jet propulsion devices, machines/engines, etc., can solve the problems of limited energy supply, limited effect, and accelerated combustion speed, and achieve rapid installation and disassembly, and reduce the contact area , avoid the effect of taking up more space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

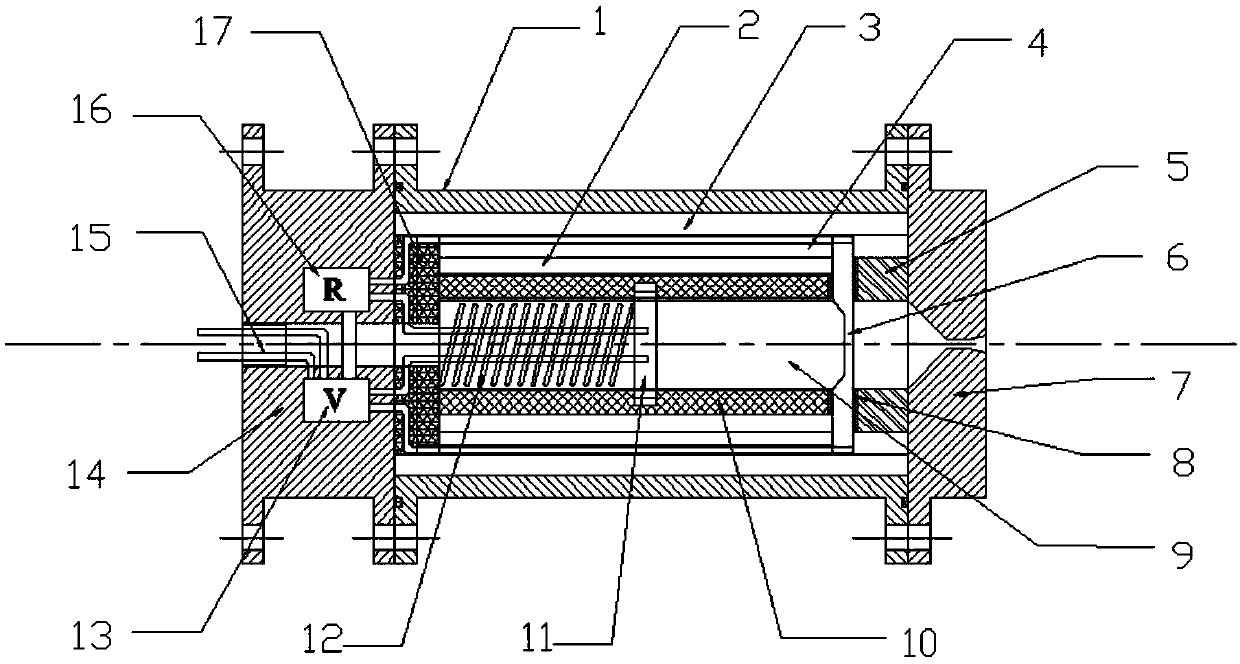

[0027] Below in conjunction with accompanying drawing, the present invention will be further described

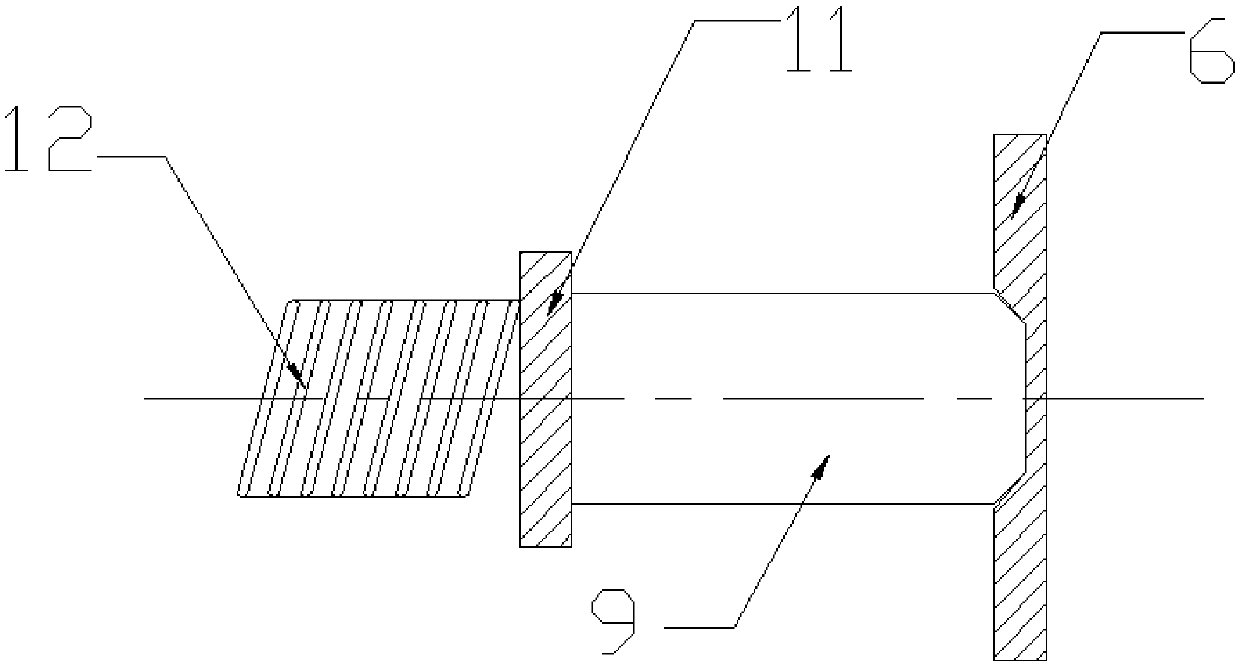

[0028] Such as figure 1 As shown, the present invention includes a combustion chamber housing 1, a corundum insulating layer 2, a silicon rubber insulating layer 3, a heat protection layer 4, an electrode fixing sleeve 5, a combustion surface electrode 6, a nozzle 7, an asbestos gasket 8, an electric control solid Propellant grain 9, electrode fixing device 10, sliding electrode 11, spring 12, voltage controller 13, fixed sealing end 14, electrode pin 15, resistance monitor 16 and lead terminal insulating plate 17. The electronically controlled solid propellant grain 9 is installed in the combustion chamber housing 1, the front end of the electrically controlled solid propellant grain 9 is in contact with the combustion surface electrode 6, and the rear end is in contact with the sliding electrode 11, and the spring 12 pushes the sliding electrode 11 and The electrically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com