A platform burning boron-containing fuel-rich propellant

A fuel-rich propellant and fuel technology, which is used in offensive equipment, compressed gas generation, explosives, etc., can solve the problems of unstable ballistic performance, large changes in burning rate, and reduced engine reliability, so as to improve ballistic performance and engine reliability. Reliability of work, effect of reducing pressure index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

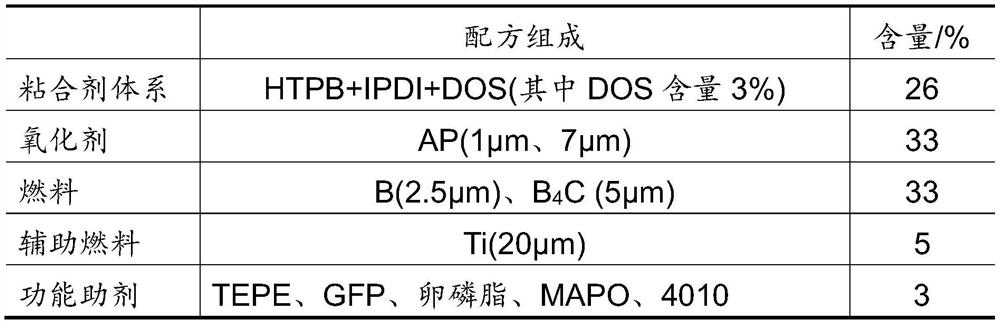

[0020] A boron-containing fuel-rich propellant, the formula composition and content of which are shown in Table 1.

[0021] Table 1: Propellant formulation of Example 1

[0022]

[0023] The properties of the propellants with the above formulations are listed in Table 2.

[0024] Table 2: Properties of the propellants formulated in Table 1

[0025]

Embodiment 2

[0027] A boron-containing fuel-rich propellant, the composition and content of which are shown in Table 3.

[0028] Table 3: Propellant formulation of Example 2

[0029]

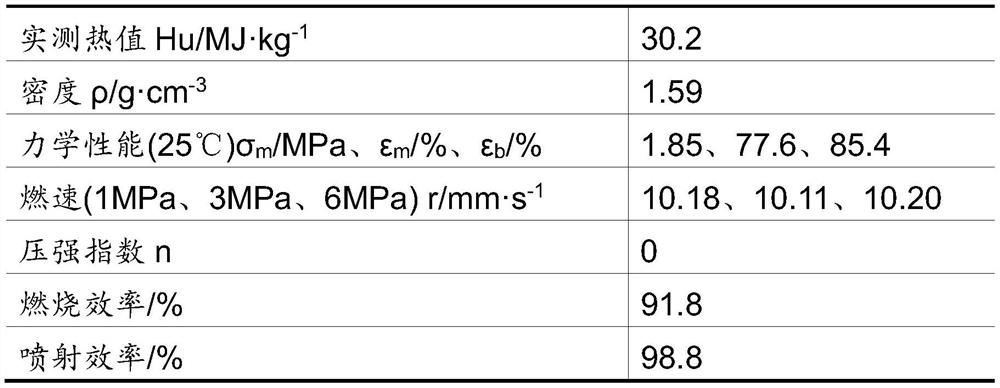

[0030] The properties of the propellants formulated above are listed in Table 4.

[0031] Table 4: Properties of the propellants formulated in Table 3

[0032]

Embodiment 3

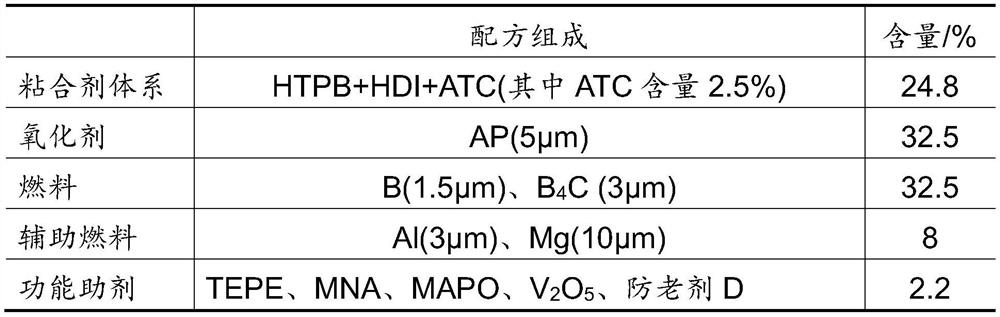

[0034] A boron-containing fuel-rich propellant, the formula composition and content of which are shown in Table 5.

[0035] Table 5: Propellant formulation of Example 3

[0036]

[0037] The properties of the propellants formulated above are listed in Table 6.

[0038] Table 6: Performance of the formula propellant of embodiment 3

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com