Concrete filled steel tubular structure internally provided with composite tubes and seawater sea sand concrete

A technology of concrete filled steel tubes and composite pipes, which is applied to building components, building structures, columns, etc., can solve the problems of unsuitable sea sand resources, lack of effective ways to directly utilize sea sand resources, disadvantageous cost savings and construction operations, etc. Conducive to sustainable development, assembly development, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

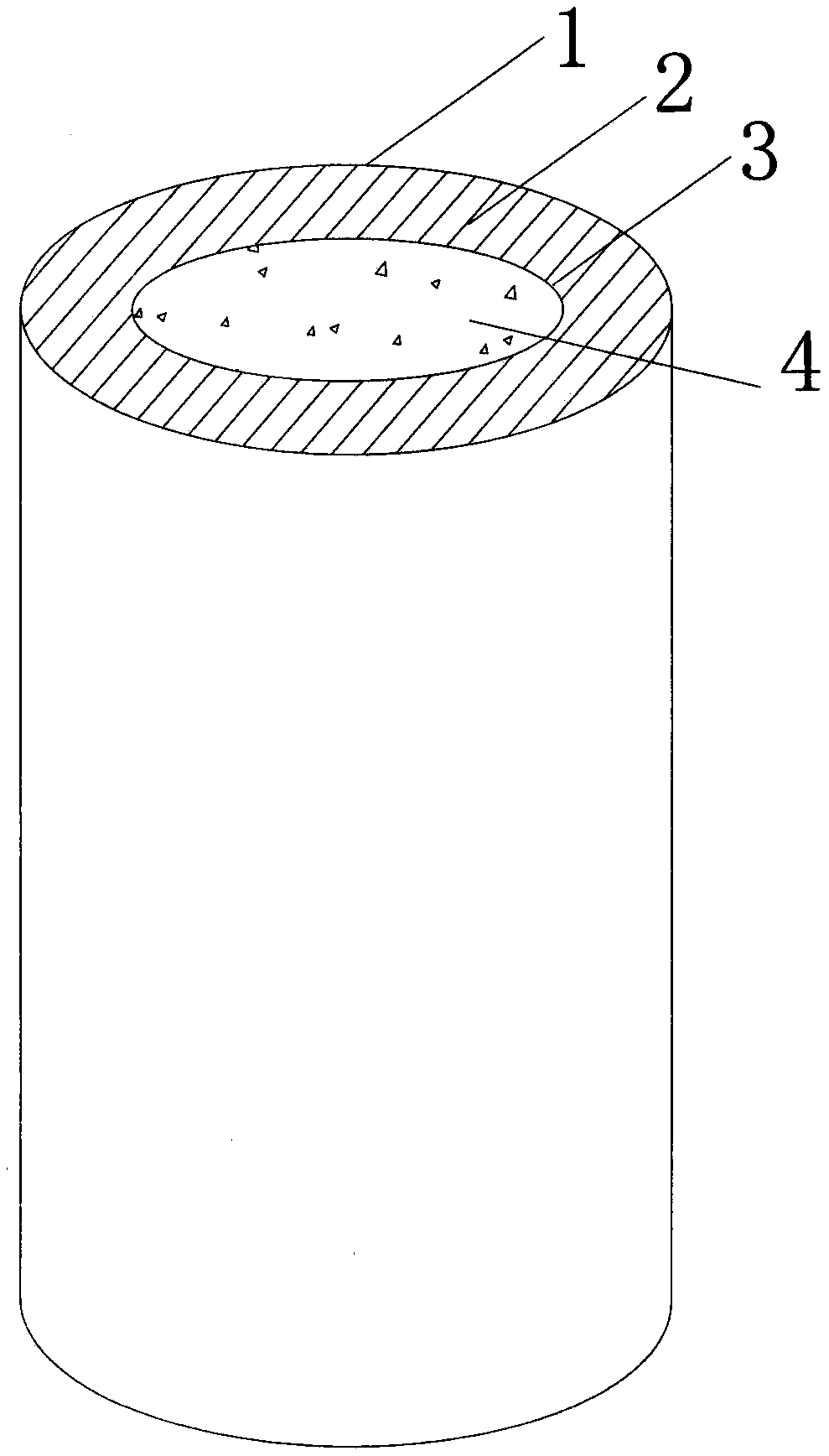

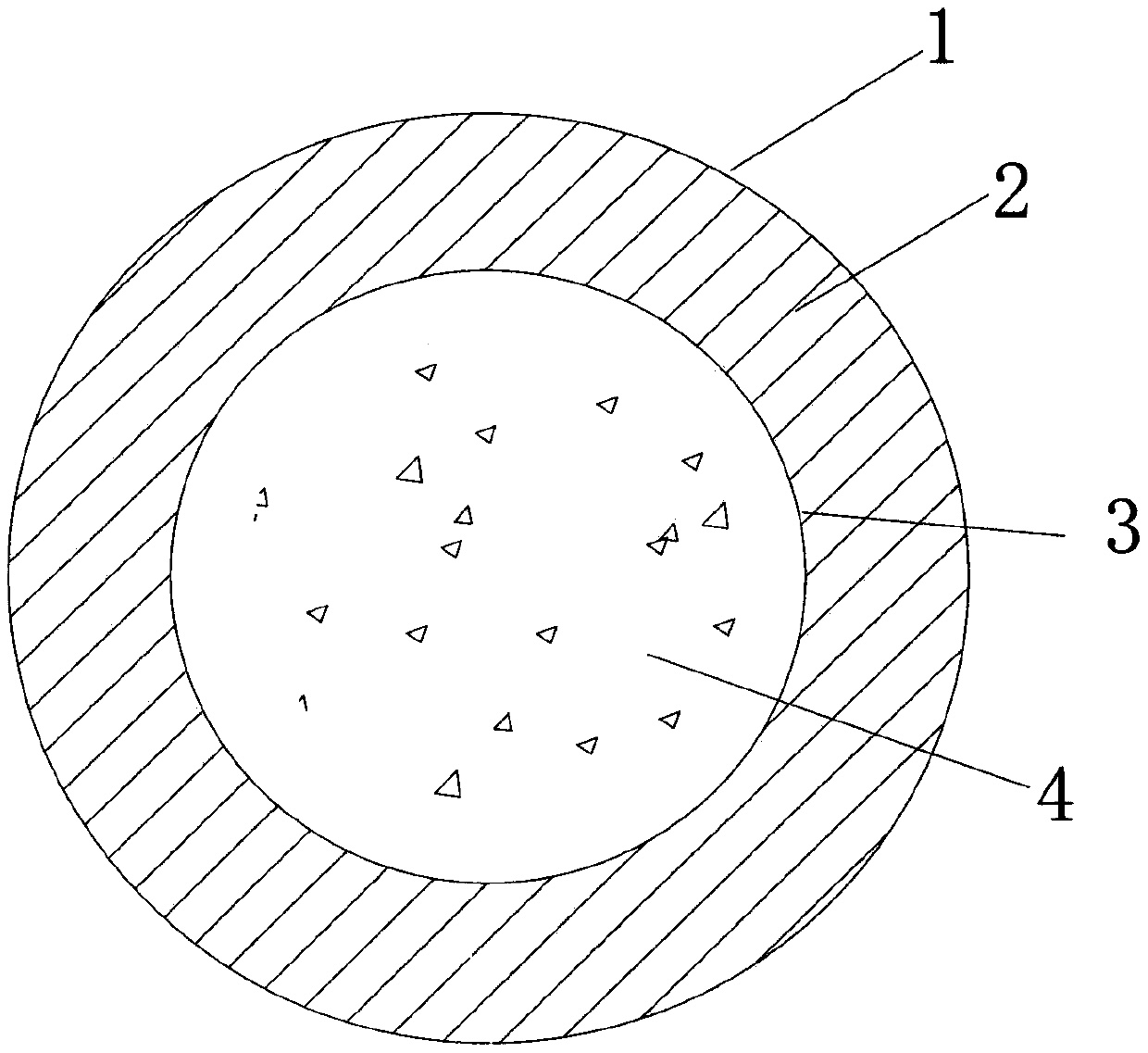

[0039] Such as Figure 1-Figure 2 As shown, a steel pipe concrete structure with built-in composite pipe seawater sea sand concrete includes steel pipe 1 , ordinary concrete 2 , composite pipe 3 , and seawater sea sand concrete 4 . A composite pipe 3 is concentrically distributed inside the cross section of the steel pipe 1, seawater sea sand concrete 4 is filled inside the cross section of the composite pipe 3, the gap between the composite pipe 3 and the steel pipe 1 is poured and filled with ordinary concrete 2, and the steel pipe 1 is a circular steel pipe , the steel pipe 1, the ordinary concrete 2, the composite pipe 3 and the seawater sea sand concrete 4 are bonded by concrete pouring to form an integral component.

Embodiment 2

[0041] Such as Figure 3-Figure 4 As shown, a steel pipe concrete structure with built-in composite pipe seawater sea sand concrete includes steel pipe 1 , ordinary concrete 2 , composite pipe 3 , and seawater sea sand concrete 4 . A composite pipe 3 is eccentrically distributed inside the cross section of the steel pipe 1, seawater sea sand concrete 4 is filled inside the cross section of each composite pipe 3, the gap between the composite pipe 3 and the steel pipe 1 is poured and filled with ordinary concrete 2, and the steel pipe 1 is circular Steel pipes, steel pipes 1, ordinary concrete 2, composite pipes 3 and seawater sea sand concrete 4 are bonded by concrete pouring to form integral components.

Embodiment 3

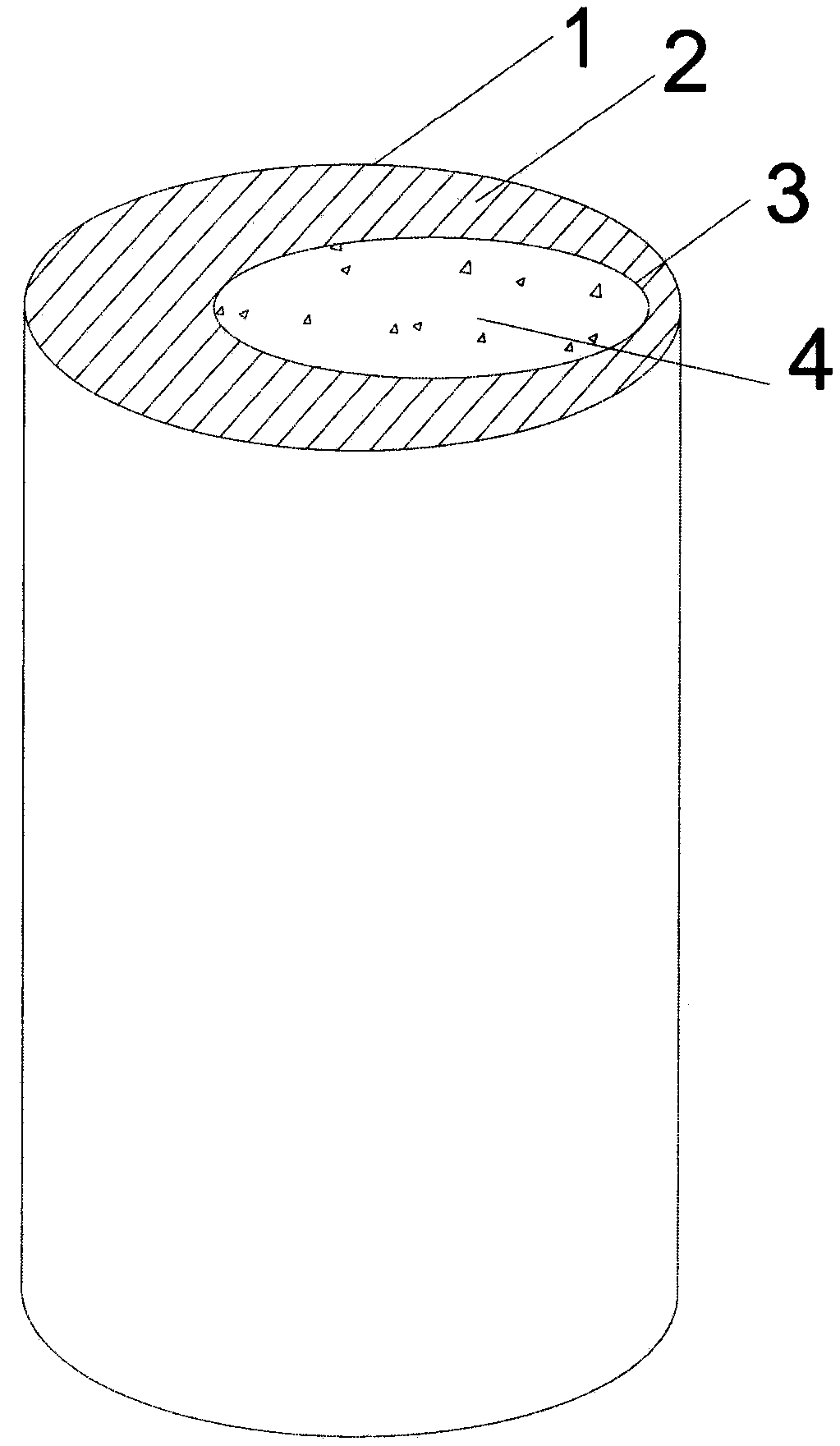

[0043] Such as Figure 5-Figure 6 As shown, a steel pipe concrete structure with built-in composite pipe seawater sea sand concrete includes steel pipe 1 , ordinary concrete 2 , composite pipe 3 , and seawater sea sand concrete 4 . Four composite pipes 3 are evenly arranged inside the section of steel pipe 1, seawater sea sand concrete 4 is filled inside the section of each composite pipe 3, the gap between composite pipe 3 and steel pipe 1 is poured and filled with ordinary concrete 2, and steel pipe 1 is a circular steel pipe , the steel pipe 1, the ordinary concrete 2, the composite pipe 3, and the seawater sea sand concrete 4 are bonded by concrete pouring to form an integral component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com