Sludge drying and incineration system

A technology of sludge drying and sludge, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of increasing the cost of sludge drying and incineration and not being able to effectively use it Problems such as waste and waste heat utilization rate are not high, and the design is reasonable, the energy consumption and cost of drying are reduced, and the effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

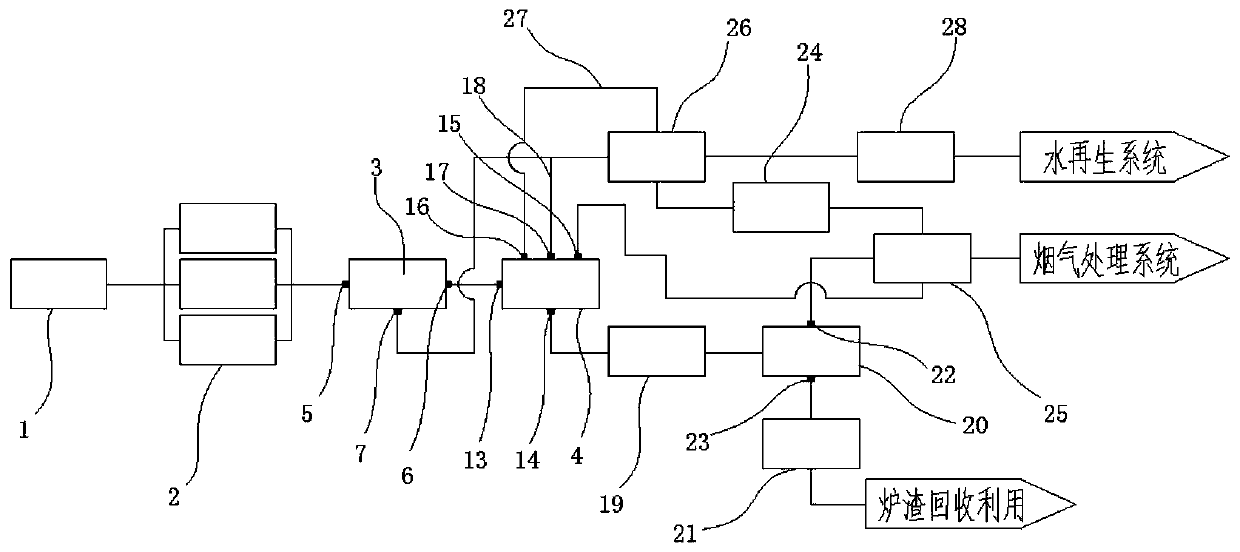

[0040] A sludge drying and incineration system is characterized in that it includes a sludge tank 1 for storing sludge, a drying system for sludge drying, an incineration system for sludge incineration and slagging, and a Water reclamation system for sludge moisture recovery treatment and heat recovery system for thermal energy recovery and utilization.

Embodiment 2

[0042] A sludge drying and incineration system in this embodiment, wherein the drying system includes an evaporation pool 2, a centrifugal dryer 3 and a heat source dryer 4;

[0043] The number of the evaporation pools 2 is multiple, and the multiple evaporation pools 2 are arranged in sequence, and receive the sludge from the sludge pool 1 in sequence, and the centrifugal dryer 3 includes a first inlet 5, a first outlet 6 and a water outlet 7 , the first inlet 5 communicates with the evaporation pool 2 through a pipeline, and adjusts the communication order with multiple evaporation pools 2 through a multi-way valve, and the first outlet 6 communicates with the heat source drier 4;

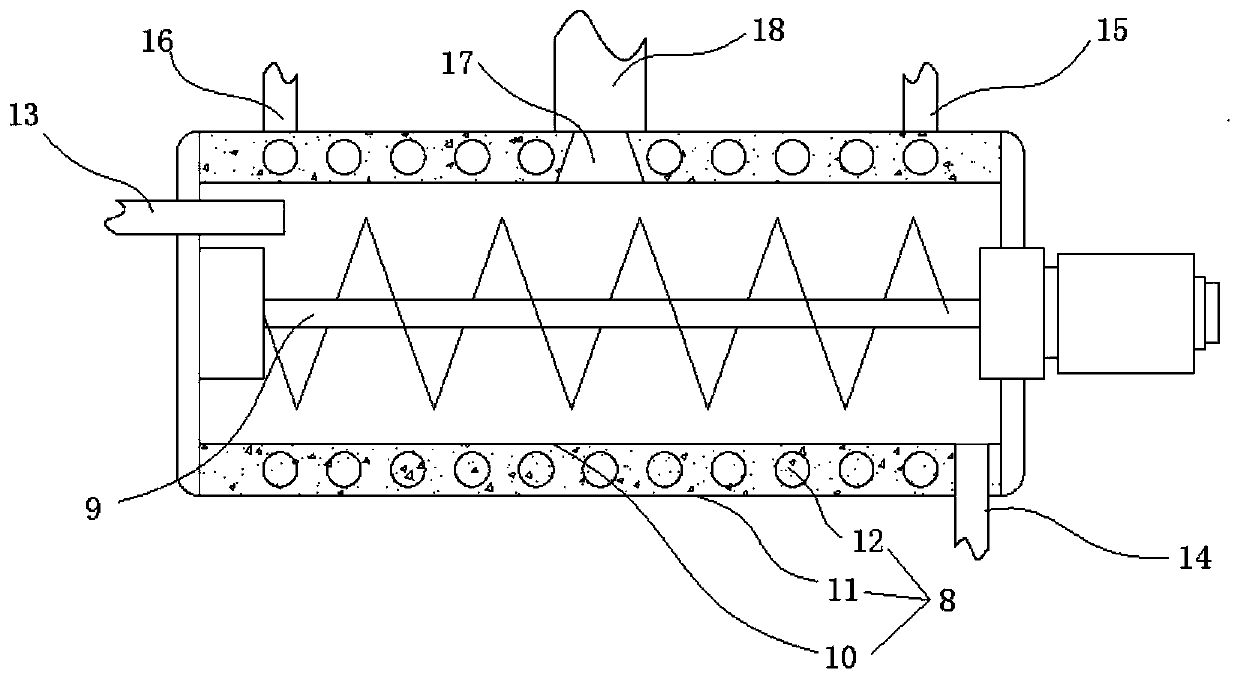

[0044] The heat source dryer 4 includes a drying shell 8 and an auger 9, and the drying shell 8 is composed of an inner shell 10, an outer shell 11, and a heat conduction coil 12 arranged between the inner shell 10 and the outer shell 11. , the inner casing 10 and the outer casing 11 are nested a...

Embodiment 3

[0050] A sludge drying and incineration system in this embodiment, wherein the incineration system includes a sludge intermediate bin 19, an incinerator 20, and a screening and slag removal machine 21, and the sludge intermediate bin 19 communicates with the second outlet 14 , receive the sludge, and transport the sludge to the incinerator 20 through the pipeline. The incinerator 20 includes a waste gas outlet 22 and a slag discharge port 23. The discharged incineration slag, the waste gas outlet 22 is connected to the waste gas pipeline, and the waste gas pipeline is connected to the flue gas treatment system;

[0051] The screening and slag removing machine 21 screens the incineration slag into granular slag and lumpy slag according to the particle size of the incineration slag, so as to facilitate subsequent slag recovery.

[0052] In this embodiment, an incinerator is used to incinerate the sludge. The incinerator can be an incinerator, or a power generation boiler can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com