Preparation method and application of PVDF/UiO-66-NH2 imprinted composite membrane

A uio-66-nh2, composite membrane technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of limited use range, inability to achieve selective separation, low specificity, etc., and achieve low prices. , excellent anti-fouling performance, the effect of improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

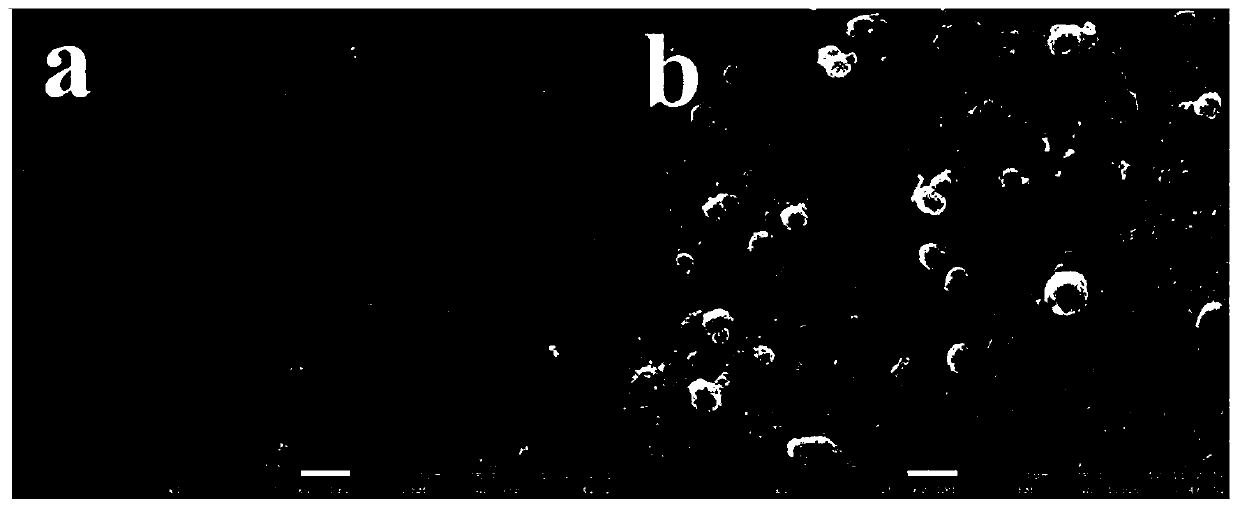

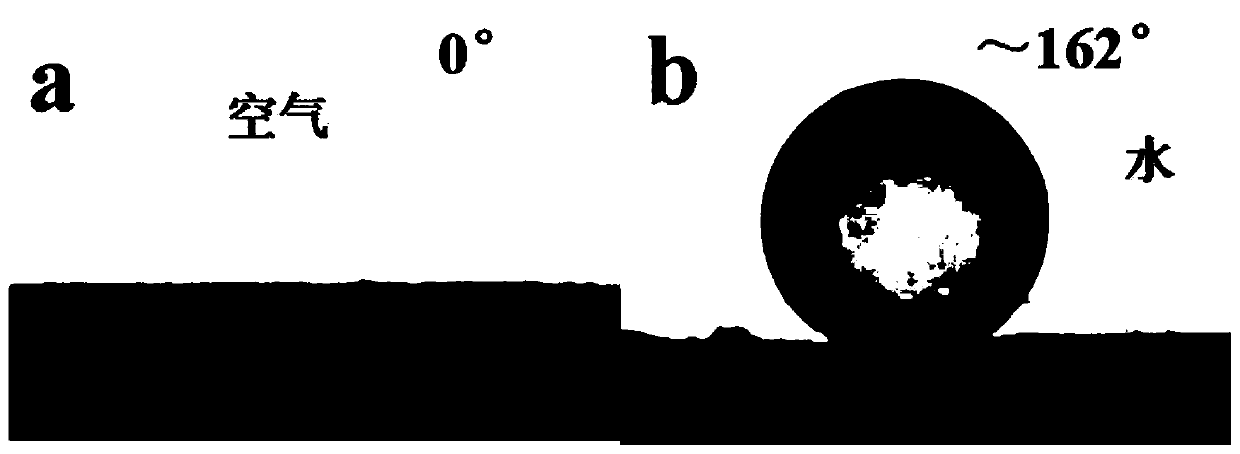

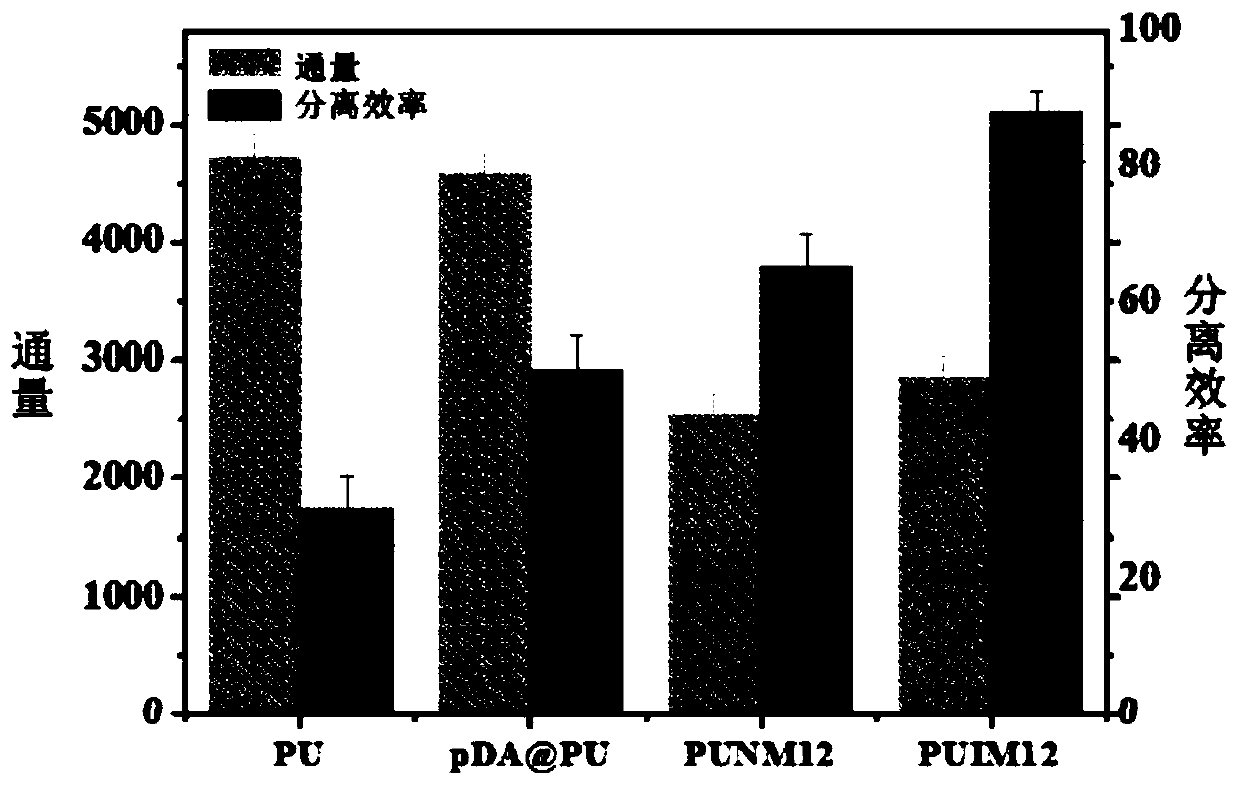

Image

Examples

Embodiment 1

[0029] (1) UiO-66-NH 2 Preparation of nanoparticles: 141 mg 2-aminoterephthalic acid, 181 mg ZrCl 4 and 3 mL of formic acid were dissolved in 30 mL of dimethylformamide (DMF) solution, poured into a hydrothermal kettle, and subjected to constant temperature hydrothermal reaction at 120°C for 24 hours; after natural cooling, DMF and ethanol solution were centrifugally washed and dried to obtain UiO-66-NH 2 Nanoparticles;

[0030] (2) PVDF / UiO-66-NH 2 Preparation of hybrid film (PU hybrid film): 0.2 g of UiO-66-NH prepared in step (1) 2 Nanoparticles were dispersed into an ethanol / water mixed solution with a volume ratio of 1:4 as a coagulation bath; 3 g of PVDF was dissolved in 30 mL of N-methylpyrrolidone (NMP) solution, and mechanically stirred at 50 °C for 12 h to obtain PVDF Casting solution; put PVDF in a coagulation bath at 25°C for 6 h to delay phase inversion to obtain a PU hybrid film;

[0031] (3) Dopamine-modified PU membrane (pDA@PU): immerse the PU hybrid memb...

Embodiment 2

[0039] (1) UiO-66-NH 2 Preparation of nanoparticles: 281mg 2-aminoterephthalic acid, 362mg ZrCl 4 and 4 mL of formic acid were dissolved in 40 mL of dimethylformamide (DMF) solution, poured into a hydrothermal kettle, and subjected to constant temperature hydrothermal reaction at 110 °C for 30 h; after natural cooling, DMF and ethanol solution were centrifugally washed and dried. Get UiO-66-NH 2 Nanoparticles;

[0040] (2) PVDF / UiO-66-NH 2 Preparation of hybrid film (PU hybrid film): 0.3 g of UiO-66-NH prepared in step (1) 2 Nanoparticles were dispersed into an ethanol / water mixed solution with a volume ratio of 1:4 as a coagulation bath, 4 g of PVDF was dissolved in 40 mL of N-methylpyrrolidone (NMP) solution, and mechanically stirred at 50 °C for 12 h to obtain PVDF Casting solution; put PVDF in a coagulation bath at 25°C for 6 h to delay phase inversion to obtain a PU hybrid film;

[0041] (3) Dopamine-modified PU membrane (pDA@PU): immerse the PU hybrid membrane prepa...

Embodiment 3

[0044] (1) UiO-66-NH 2 Preparation of nanoparticles: 422mg 2-aminoterephthalic acid, 543mg ZrCl 4 and 5 mL of formic acid were dissolved in 50 mL of dimethylformamide (DMF) solution, poured into a hydrothermal kettle, and subjected to a constant temperature hydrothermal reaction at 130°C for 20 h; after natural cooling, centrifugal washing with DMF and ethanol solution, and drying , to get UiO-66-NH 2 Nanoparticles;

[0045] (2) PVDF / UiO-66-NH 2 Preparation of hybrid film (PU hybrid film): 0.4 g of UiO-66-NH prepared in step (1) 2 Nanoparticles were dispersed into an ethanol / water mixed solution with a volume ratio of 1:4 as a coagulation bath, 5 g of PVDF was dissolved in 50 mL of N-methylpyrrolidone (NMP) solution, and mechanically stirred at 50 °C for 12 h to obtain PVDF Casting solution; put PVDF in a coagulation bath at 30°C for 5 hours to delay phase inversion to obtain a PU hybrid film;

[0046] (3) Dopamine-modified PU membrane (pDA@PU): immerse the PU hybrid memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com