High-temperature-resistant and environment-friendly plastic material for textile machinery and preparation method of high-temperature-resistant and environment-friendly plastic material

A technology for plastic materials and textile machinery, which is applied in the field of high-temperature-resistant and environmentally-friendly plastic materials for textile machinery and its preparation. High temperature performance, effect of improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

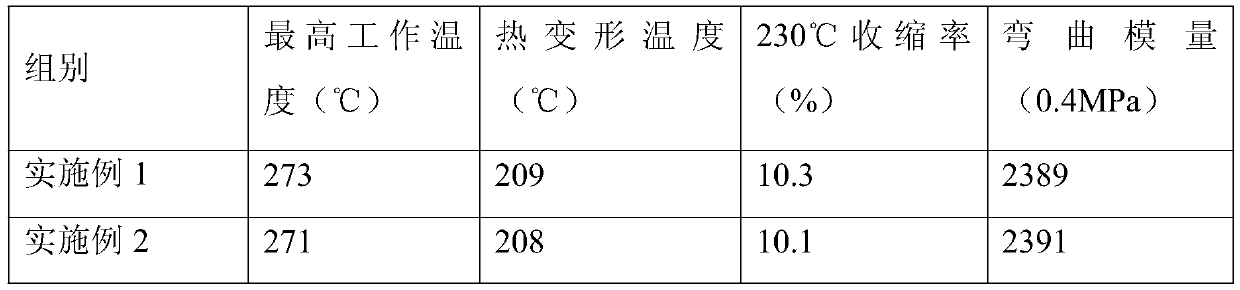

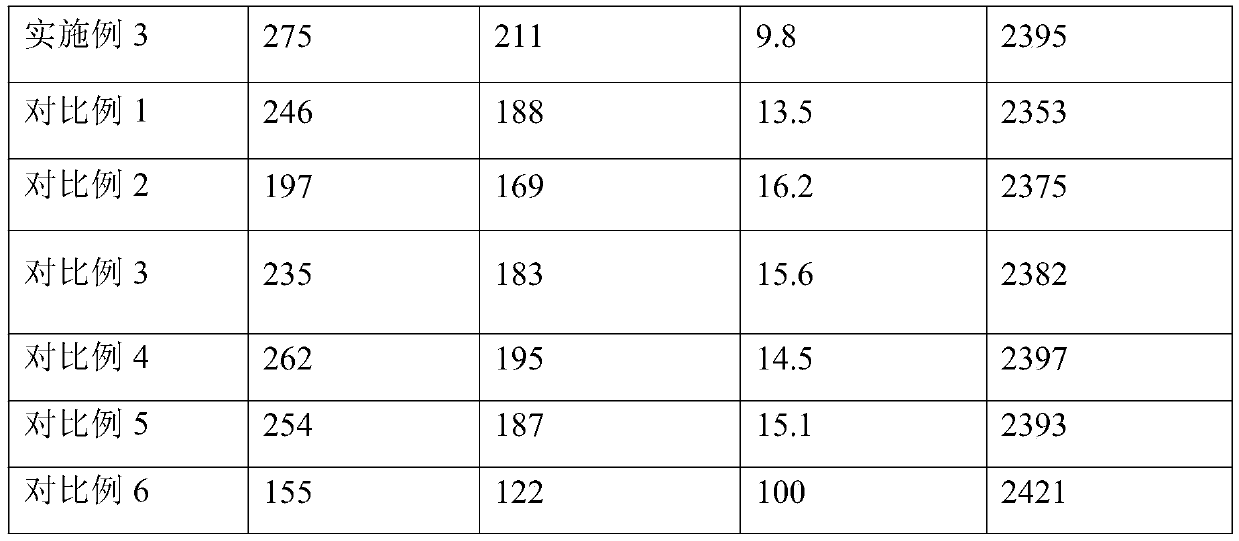

Examples

Embodiment 1

[0031] A method for preparing a high-temperature-resistant environment-friendly plastic material for textile machinery in this embodiment comprises the following steps:

[0032] Step 1, weigh each component raw material as required: 45g of high temperature resistant resin, 20g of plastic additives, 10g of zirconium quartz powder, 7g of nanoporous fiber, 5g of andalusite, Ni 3 Al powder 2g, high temperature additive 1g;

[0033] The preparation method of plastic additives: Add aluminum dihydrogen phosphate into a high-temperature stirring tank, then add magnesium antimonide whiskers with 10% weight of aluminum dihydrogen phosphate and stir at a speed of 600r / min for 25 minutes, then add magnesium antimonide Nano-TiC ceramic powder with a total whisker content of 35%, and finally stirred at a low speed of 200r / min for 3h;

[0034] Step 2: Add high-temperature resistant resin and plastic additives to a high-speed shearing machine for shearing treatment. The shearing treatment sp...

Embodiment 2

[0043] A method for preparing a high-temperature-resistant environment-friendly plastic material for textile machinery in this embodiment comprises the following steps:

[0044] Step 1. Weigh the raw materials of each component as required: 55g of high temperature resistant resin, 25g of plastic additives, 20g of zirconium quartz powder, 13g of nanoporous fiber, 9g of andalusite, Ni 3 Al powder 5g, high temperature additive 3g;

[0045] Preparation method of plastic additives Add aluminum dihydrogen phosphate into a high-temperature stirred tank, then add magnesium antimonide whiskers with 20% weight of aluminum dihydrogen phosphate and stir for 35 minutes at a speed of 800r / min, and then add magnesium antimonide Nano-TiC ceramic powder with a total whisker content of 35%, and finally stirred at a low speed of 200r / min for 5h;

[0046] Step 2: Add the high-temperature resistant resin and plastic additives to the high-speed shearing machine for shearing treatment. The shearing...

Embodiment 3

[0055] A method for preparing a high-temperature-resistant environment-friendly plastic material for textile machinery in this embodiment comprises the following steps:

[0056] Step 1, weigh each component raw material as required: 50g of high temperature resistant resin, 22.5g of plastic additives, 15g of zirconium quartz powder, 10g of nanoporous fiber, 7g of andalusite, Ni 3 Al powder 3.5g, high temperature additive 2g;

[0057] The preparation method of plastic additives: Add aluminum dihydrogen phosphate into a high-temperature stirred tank, then add magnesium antimonide whiskers with 15% weight of aluminum dihydrogen phosphate and stir for 30 minutes at a speed of 700r / min, and then add magnesium antimonide Nano-TiC ceramic powder with a total whisker content of 35%, and finally stirred at a low speed of 200r / min for 4h;

[0058] Step 2: Add the high temperature resistant resin and plastic additives to the high-speed shearing machine for shearing treatment. The shearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com