Terbium coordination polymer for separating propyne/propylene gas mixture and preparation method thereof

A technology of coordination polymer and tetragonal crystal system, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high energy consumption, low selectivity, etc., and achieve good repeatability, good separation, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

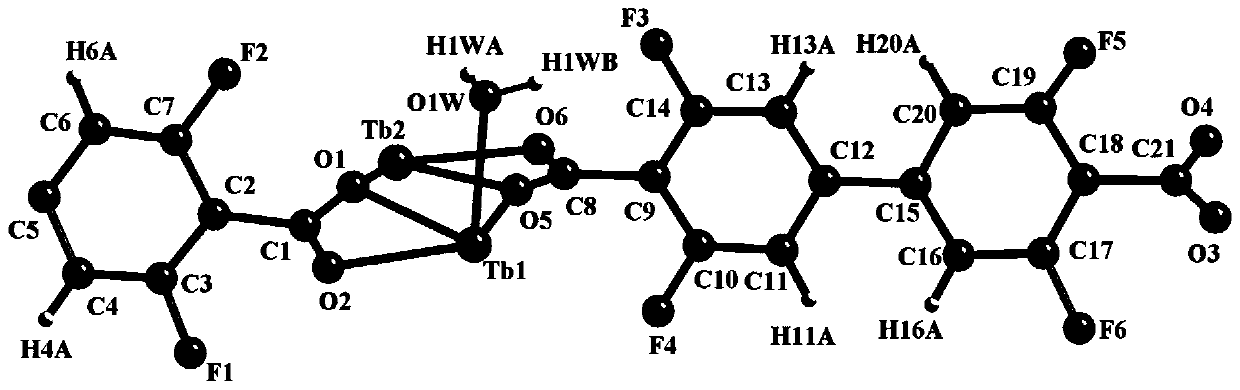

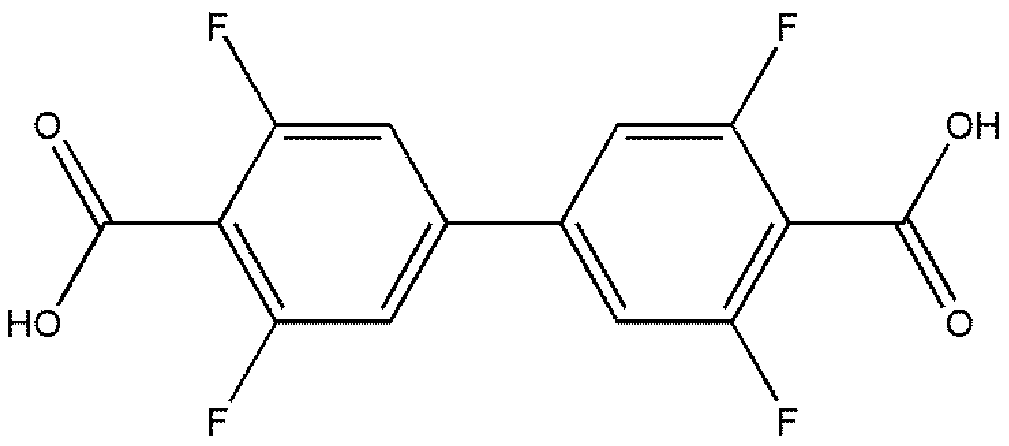

[0024] Mix terbium chloride, 3,3',5,5'-tetrafluorobiphenyl-4,4'-dicarboxylic acid and o-fluorobenzoic acid in a molar ratio of 2:1:5, and put in a 2 ml The volume of N,N-dimethylformamide solvent is 20 ml in a polytetrafluoroethylene-lined autoclave, the amount of terbium chloride is controlled at 5.5 mg, and then reacted at a constant temperature of 358K for 1 day to obtain colorless crystals , that is, the terbium coordination polymer [Tb 2 ·C 42 h 12 f 12 o 12 ·H 2 O], the yield was 48%.

Embodiment 2

[0026] Mix terbium nitrate, 3,3',5,5'-tetrafluorobiphenyl-4,4'-dicarboxylic acid and o-fluorobenzoic acid in a molar ratio of 2:1:5, and put them in a container containing 2 ml of N , the volume of N-dimethylformamide solvent is in the autoclave of polytetrafluoroethylene lining of 20 milliliters, the amount of terbium chloride is controlled at 7.0 milligrams, then constant temperature reacts 1 day under 358K, obtains colorless crystal, Terbium coordination polymer [Tb 2 ·C 42 h 12 f 12 o 12 ·H 2 O] with a yield of about 43%.

Embodiment 3

[0028] Mix terbium acetate, 3,3',5,5'-tetrafluorobiphenyl-4,4'-dicarboxylic acid and o-fluorobenzoic acid in a molar ratio of 2:1:5, and put them in a container containing 2 ml of N , the volume of N-dimethylformamide solvent is in the autoclave of polytetrafluoroethylene lining of 20 milliliters, the amount of terbium chloride is controlled at 6.7 milligrams, then constant temperature reacts 1 day under 358K, obtains colorless crystal, Terbium coordination polymer [Tb 2 ·C 42 h 12 f 12 o 12 ·H 2 O] with a yield of about 41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com