Antioxidant-free vitamin A microcapsule preparation and preparation method thereof

A technology of antioxidants and vitamins, applied in microcapsules, food ingredients as anticaking agents, medical preparations of non-active ingredients, etc., can solve the problems of no bioavailability and achieve high bioavailability and high embedding rate , high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

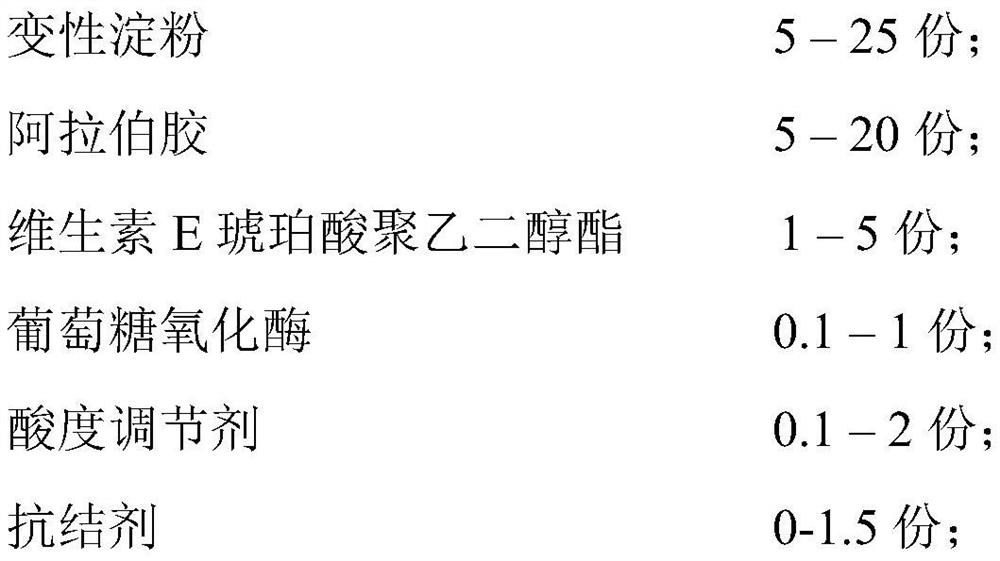

Method used

Image

Examples

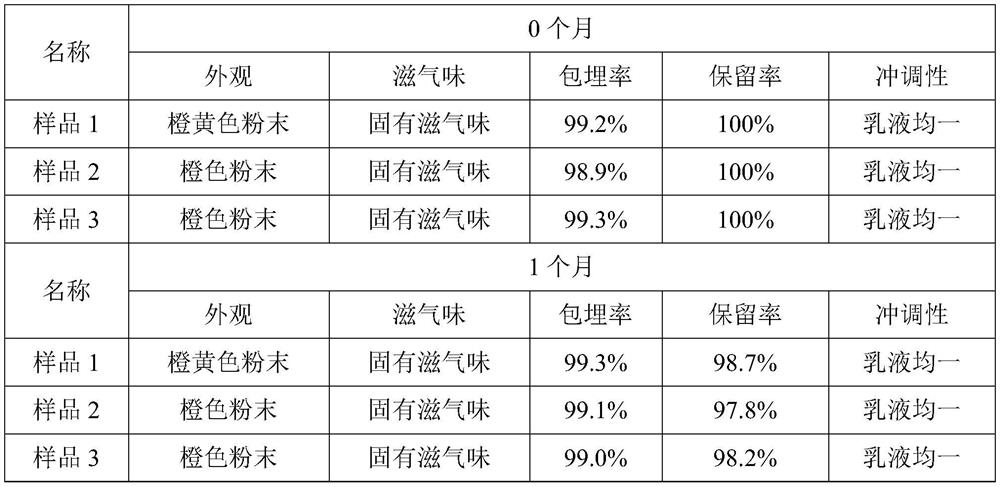

Embodiment 1

[0030] Weigh 409g of water into a 1000mL beaker at a temperature of 62°C, add 125g of sodium starch octenyl succinate and 100g of gum arabic to it, stir until completely dissolved, and lower the temperature to 35°C for later use. Add 6g of sodium bicarbonate into the water phase, control the pH at 6.8-7.1, and then add 4g of glucose oxidase. Mix 7.5g of vitamin E polyethylene glycol succinate and 252.5g of vitamin A acetate, melt in a 75°C water bath, stir evenly, and cool down to 35°C to obtain an oil phase. Slowly pour the oil phase into the water phase, shear emulsify at 35°C for 0.5h, homogenize twice under 40MPa high pressure, and then spray dry, the air inlet temperature is 170°C, and the outlet air temperature is 84°C. Sieve, add silicon dioxide, obtain vitamin A acetate microcapsule powder, record as sample 1.

Embodiment 2

[0032] Weigh 1000g of water into a 2000mL beaker at a temperature of 65°C, add 200g of sodium starch octenyl succinate and 150g of gum arabic, stir until completely dissolved, and lower the temperature to 38°C for later use. Add 5g of calcium hydroxide into the water phase, control the pH at 6.9-7.5, and then add 10g of glucose oxidase. Mix 20g of vitamin E polyethylene glycol succinate and 605g of vitamin A acetate, melt in an 80°C water bath, stir evenly, and cool down to 38°C to obtain an oil phase. Slowly pour the oil phase into the water phase, shear emulsify at 38°C for 0.5h, homogenize twice under 55MPa high pressure, and then spray dry, the air inlet temperature is 180°C, and the outlet air temperature is 90°C. Sieve, add silicon dioxide, obtain vitamin A acetate microcapsule powder, record as sample 2.

Embodiment 3

[0034] Weigh 2000g of water into a 3000mL beaker at a temperature of 75°C, add 240g of phosphorylated starch and 260g of gum arabic into it, stir until completely dissolved, and lower the temperature to 40°C for later use. Add 4g of sodium hydroxide into the water phase, control the pH at 7.0-7.3, and then add 16g of glucose oxidase. Mix 60g vitamin E polyethylene glycol succinate and 1400g vitamin A palmitate, melt in a water bath at 69°C, stir evenly, cool to 40°C to obtain an oil phase. Slowly pour the oil phase into the water phase, shear and emulsify at 40°C for 1 hour, homogenize twice under 50MPa high pressure, and then spray dry, the air inlet temperature is 175°C, and the outlet air temperature is 87°C. Sieve, add silicon dioxide, obtain vitamin A acetate microcapsule powder, record as sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com