A kind of fishy-free plant-based high oil-carrying microcapsule powder and its preparation method

A plant-based, microencapsulated powder technology is applied in food science, food ingredients as antioxidants, and food forming. It can solve the problems of high production cost, low solid content, and unresolved fishy smell of plant protein powder. High embedding rate, solve the problem of fishy smell, and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

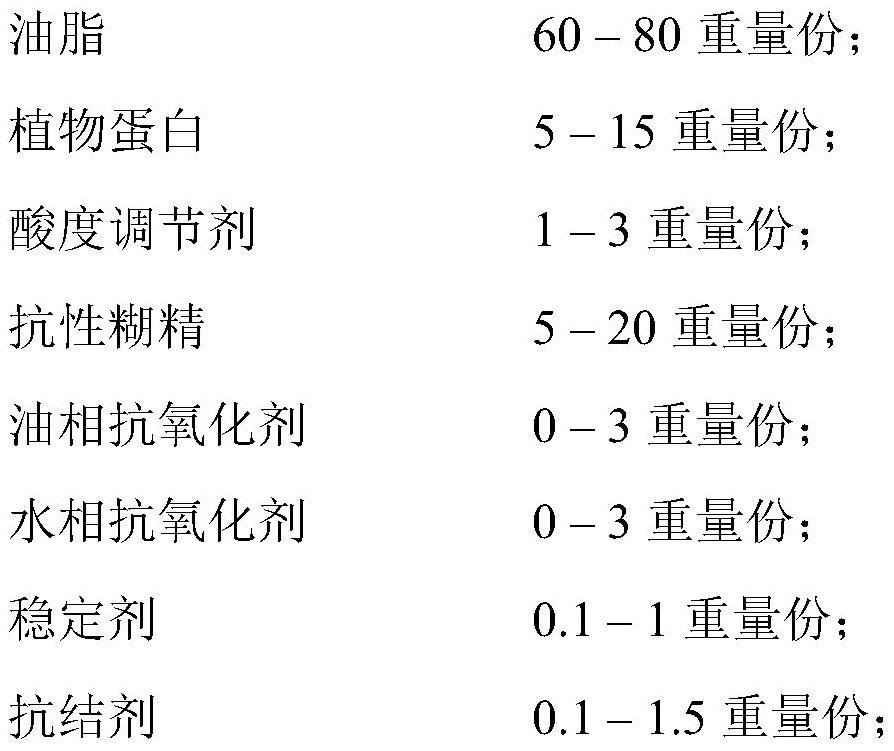

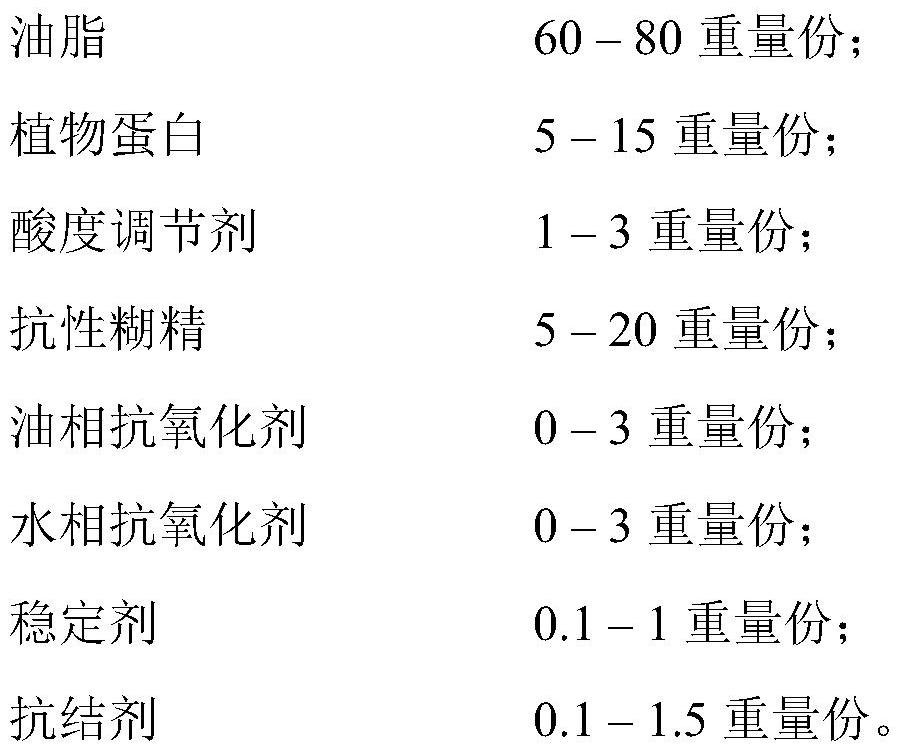

[0026] The present invention provides the preparation method of described fat microcapsule powder, comprises the following steps:

[0027] (1) Disperse 5-15 parts by weight of vegetable protein in water at 60-80°C, adjust the pH of the solution to 2.5-4, perform heat preservation and hydrolysis, and control the molecular weight of vegetable protein at 10000-25000Da;

[0028] (2) Add 5-20 parts by weight of resistant dextrin and 0.1-1 part by weight of stabilizer into (1), and stir until completely dissolved;

[0029] (3) Adjust the pH of the (2) solution to 8-9, add 0-3 parts by weight of water-phase antioxidant, and then add 42-72 parts by weight of oil, emulsify at 60-80 ° C, and then 20- 40MPa homogenization at least once;

[0030] (4) Adjust the pH of the solution of (3) to 7-7.5, add 6-24 parts by weight of oil and 0-3 parts by weight of oil phase antioxidant, emulsify at 60-80 ° C, and then 50- 70MPa high pressure homogenization at least twice;

[0031] (5) Spray-dry ...

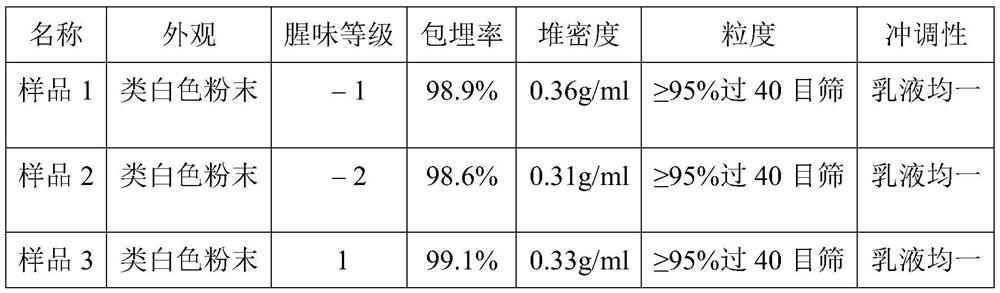

Embodiment 1

[0042]Weigh 400g of water into a 1000mL beaker at a temperature of 65°C, add 48g of soybean protein to it, stir and disperse evenly, adjust the pH of the emulsion to 2.7 with 3.2g of phosphoric acid, and carry out heat preservation and acid hydrolysis for 1.5h to obtain a protein with a molecular weight of 12000Da. Add 78.8g of resistant dextrin and 3.2g of potassium citrate into the water phase, stir to dissolve. Then adjust the pH of the system to 8.3 with 2 g of sodium hydroxide, add 0.8 g of sodium ascorbate, and stir to dissolve. Add 182g of sunflower oil, emulsify at 65°C, and then homogenize once at 30MPa. Then use 0.1g of phosphoric acid to adjust the pH of the emulsion to 7.3, then add the remaining 78g of sunflower oil and 0.1g of mixed tocopherols, emulsify at 70°C, and homogenize twice under 65MPa high pressure. The prepared emulsion was spray-dried: the inlet air temperature was 180°C, and the outlet air temperature was 90°C. Finally, 4g of silicon dioxide was ad...

Embodiment 2

[0044] Weigh 800g of water into a 2000mL beaker at a temperature of 70°C, add 120g of pea protein to it, stir and disperse evenly, adjust the pH of the emulsion to 2.6 with 5.6g of hydrochloric acid, and carry out acidolysis for 1 hour to obtain a protein with a molecular weight of 20,000Da. Add 56g of resistant dextrin and 8g of dipotassium hydrogen phosphate into the water phase and stir to dissolve. Then adjust the pH of the system to 8.8 with 4 g of calcium hydroxide, add 1.6 g of ascorbic acid, and stir to dissolve. Add 480g of soybean oil, emulsify at 70°C, and then homogenize once at 25MPa. Then adjust the pH of the emulsion to 7.5 with 0.1g hydrochloric acid, then add the remaining 120g soybean oil and 0.8g d-a-tocopherol, emulsify at 75°C, and homogenize twice under 70MPa high pressure. The prepared emulsion was spray-dried: the inlet air temperature was 170°C, and the outlet air temperature was 85°C. Finally, 8g of silicon dioxide was added to the powder and sieved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com