Pneumatic device and lithographic device

A pneumatic device and pneumatic control technology, applied in the field of lithography machines, can solve the problems such as the large volume of the pneumatic device and the inability to set a position close to the silicon wafer in the lithography equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

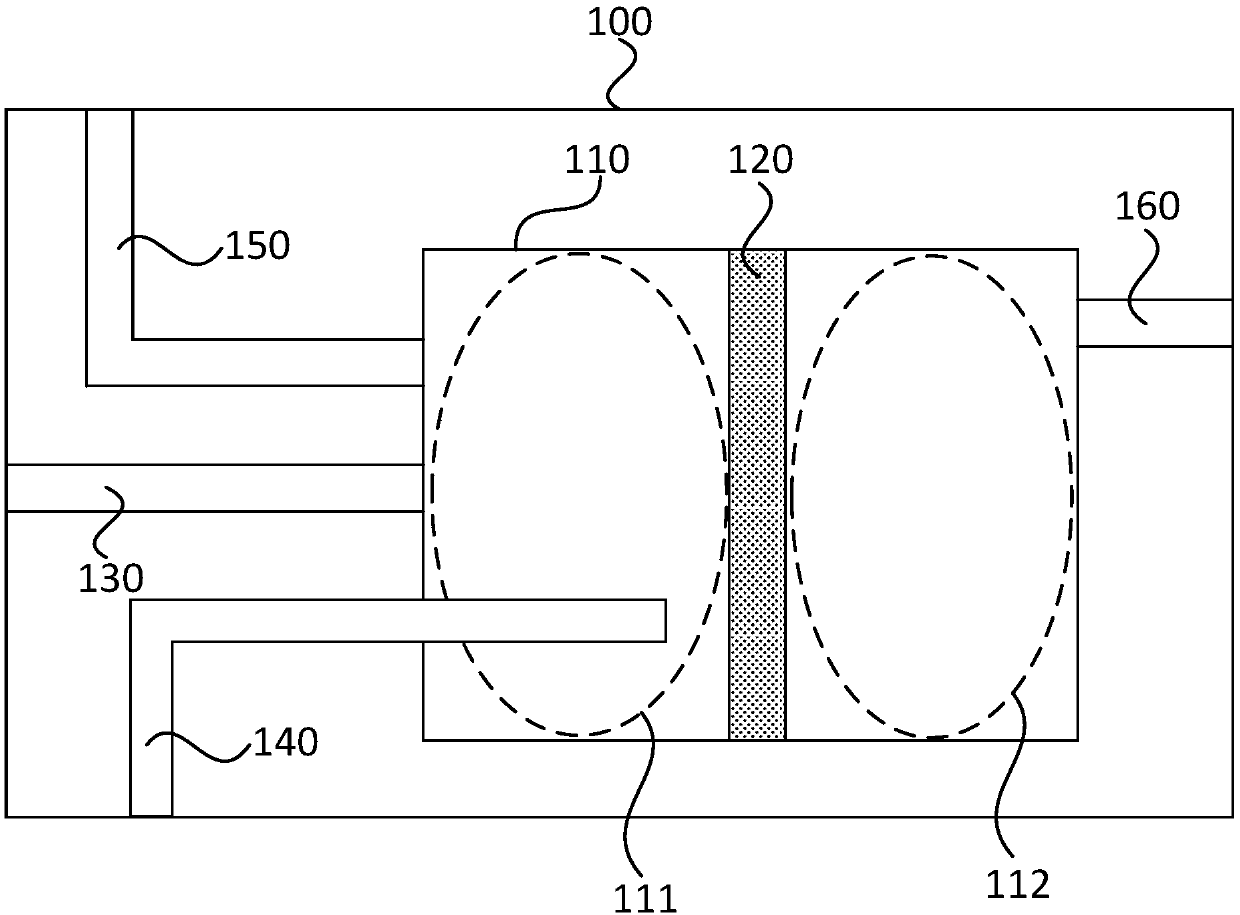

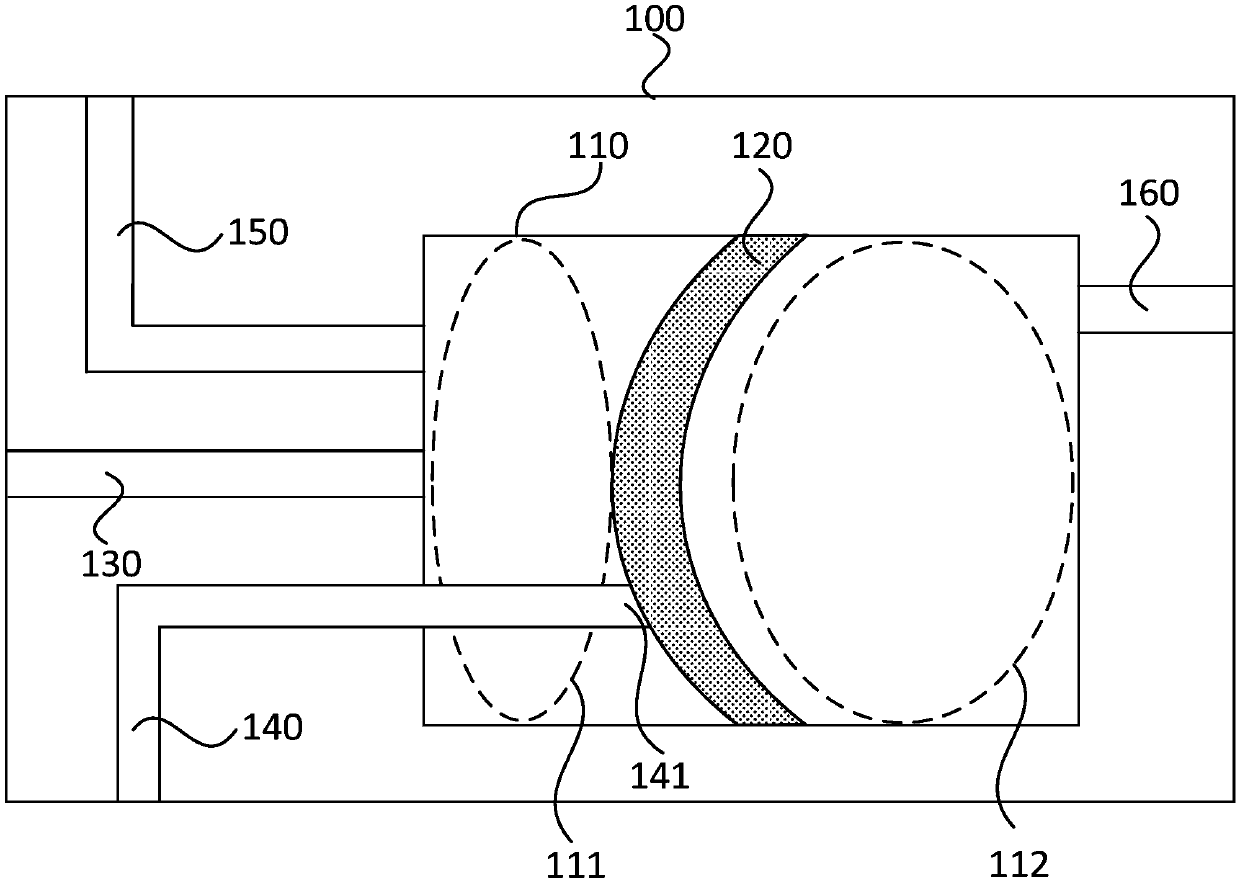

[0048] figure 1 For the sectional view of the pneumatic device provided by Embodiment 1 of the present invention, see figure 1, the pneumatic device includes an air control block 100 and an air control passage 130, and the air control block 100 is provided with a gas switching chamber 110, a flexible sheet 120, an atmospheric pipeline 140, a first vacuum branch 150 and a second vacuum branch 160, The two ends of the gas control channel 130 are respectively connected with the gas switching chamber 110 and the object to be controlled ( figure 1 not shown) connected. The gas switching chamber 110 is sealed, and the flexible sheet 120 is arranged in the gas switching chamber 110, and is used to divide the gas switching chamber 110 into a first isolation area 111 and a second isolation area 112, which are isolated from each other. The first isolation area 111 It is always connected with the first vacuum branch 150 and the air control passage 130, and the second isolation area 112...

Embodiment 2

[0055] Figure 4 For the sectional view of the pneumatic device provided by Embodiment 2 of the present invention, see Figure 4 On the basis of the first embodiment, optionally, the air control block 100 of the pneumatic device is formed by splicing the first flow distribution block 210 and the second flow distribution block 220; One side of the two diversion block 220, the second isolation area 112 is set on the side of the second diversion block 220 facing the first diversion block 111, after the first diversion block 210 and the second diversion block 220 are spliced, the first isolation area 111 and The second isolation area 112 forms the gas switching chamber 110 , and the flexible sheet 120 is located at the junction of the first flow distribution block 210 and the second flow distribution block 220 , serving as sealing surfaces of the first isolation area 111 and the second isolation area 112 respectively.

[0056] Wherein, a plurality of gas paths may be provided in ...

Embodiment 3

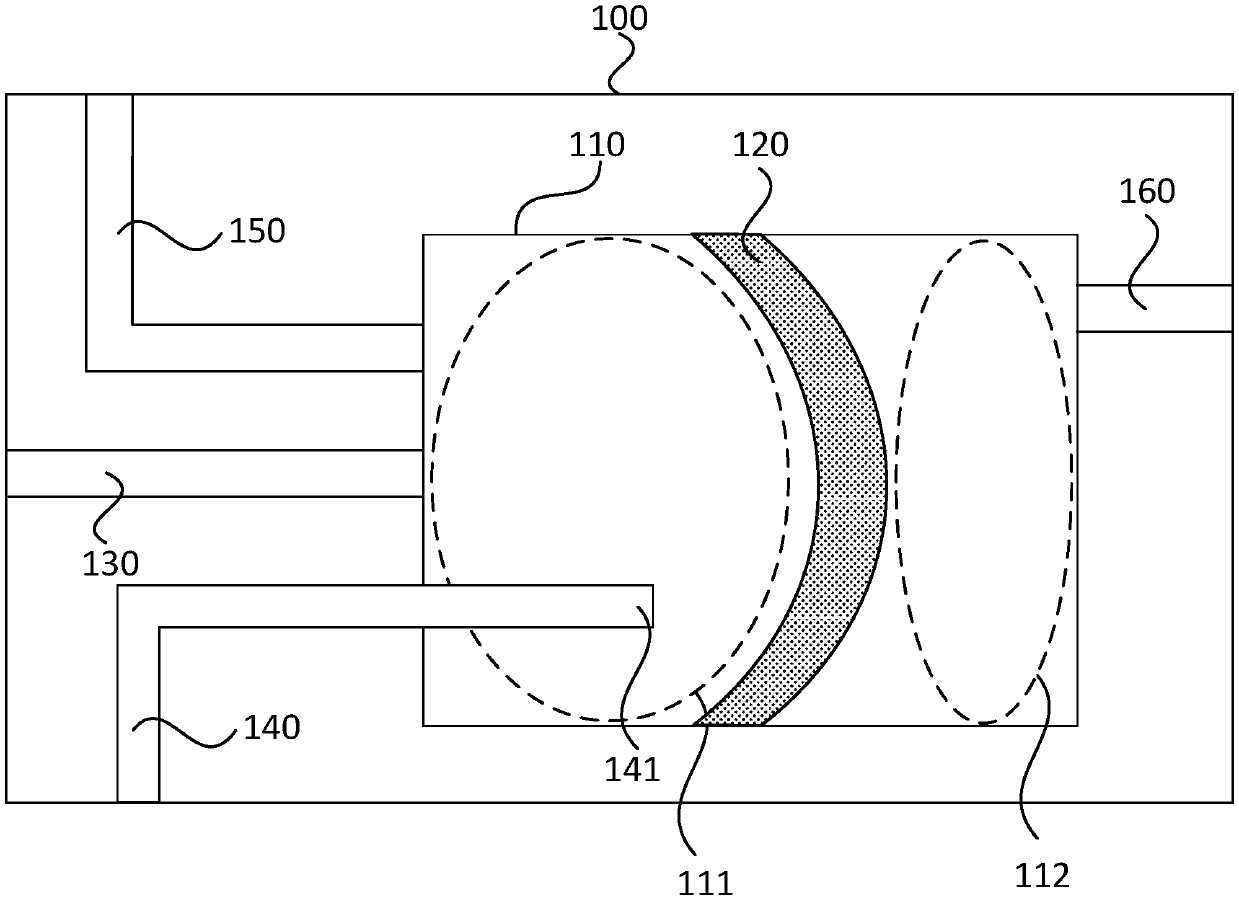

[0083] Figure 7 For the sectional view of the pneumatic device provided by Embodiment 3 of the present invention, see Figure 7 , on the basis of Embodiment 1, optionally, the second vacuum branch 160 includes a first sub-branch 161 and a second sub-branch 162, the output end of the first sub-branch 161 is vertical to the flexible sheet 120 The projection is located between the first protrusion 121 and the annular protrusion 122 , and the vertical projection of the output end of the second sub-branch 162 on the flexible sheet 120 is located in the first protrusion 121 .

[0084] When the first solenoid valve 230 switches the first vacuum branch 150 to conduction, the first vacuum branch 150 is evacuated, and the flexible sheet 120 is moved to the top 113 of the gas switching chamber 110 by the vacuum of the first vacuum branch 150 Bending deformation, the flexible sheet 120 is in close contact with the end of the isolation pipeline 240, the inner space 1111 is isolated from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com