Method for detecting type of FSW welding seam defect by using ultrasonic phased array

An ultrasonic phased array and friction stir welding technology, which is used in the analysis of solids, instruments, and materials by using sonic/ultrasonic/infrasonic waves. The effect of high detection efficiency and enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Three vertical non-penetration butt joint specimens of different lengths were prepared. The 2A14 aluminum alloy plate with a size of 200mm×150mm×8mm is used to make the butt weld. The material of the stirring head is H13 steel. The thread on the surface of the needle is a left-handed thread, the welding parameter selection speed is 950r / min, the welding speed is 75mm / min, and the inclination angle of the stirring head is 2°. The inclination angle of the butt joint surface of the test plate is processed by wire cutting and milling machine. In this embodiment, the inclination angle of 90° is selected as the vertical butt joint surface. The shape of the docking surface and the insertion position of the stirring needle are as follows: figure 1 shown.

[0033] In order to study the influence of different lengths of vertical non-penetration defects on the detection, the vertical butt joint test panels were welded with stirring heads with different lengths of left-handed thr...

Embodiment 2

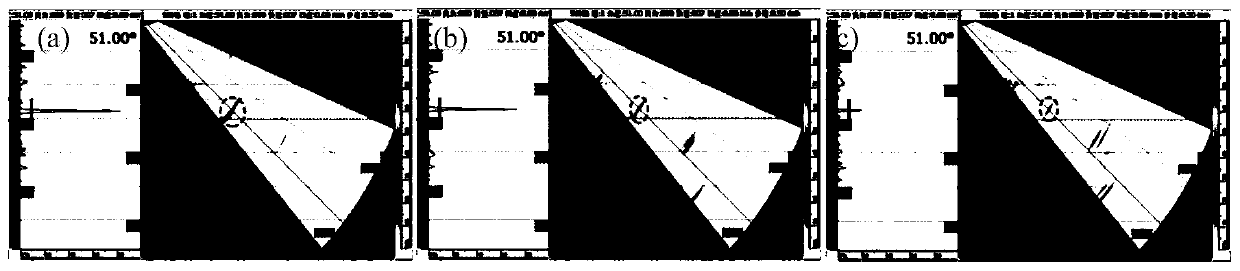

[0036] Using the same material and FSW process as in Example 1, the plate was processed at an inclination angle of 45°, and the non-threaded stirring pin was used for FSW butt jointing to obtain a welding defect test plate. Since the inclination angle of the butt joint surface of the test plate and the length of the stirring tip change compared with that of Example 1, the incomplete penetration form of the butt weld will change. Due to the low plastic flow effect caused by the non-threaded stirring needle, the prepared incomplete penetration defect is a flat interface, so that the plastic metal on the retreating side is not enough to fill the instantaneous cavity on the advancing side during the welding process, while the welding on the advancing side (welding The direction is the same as the direction of rotation of the stirring head) tunnel holes appear (such as Figure 5 shown). At the same time, the same ultrasonic phased array as in Example 1 was used to conduct phased a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com