Aqueous high-temperature-resistant thermosetting methylphenyl silicone resin and preparation method thereof

A methyl phenyl silicon, high-resistant technology, applied in the field of polymer compound synthesis, can solve the problems of changing the performance of silicone resin, not meeting environmental protection requirements, not high temperature resistance, etc., to improve heat resistance and realize self-emulsification , Good effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

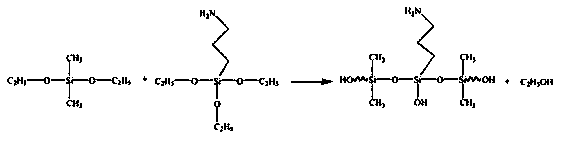

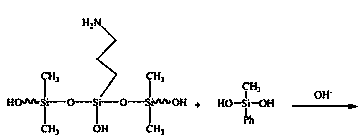

Method used

Image

Examples

Embodiment 1

[0023] Add 6.8g of polydimethylsiloxane, 2.8g of polyethylene glycol (PEG800) and 1.3g of Lewis acid catalyst (zinc chloride used in this example) and 48ml of ethanol into a 500mL three-necked flask, and stir at room temperature for 10h to obtain the prepared Obtain hydrophilic sol-gel silicone. Then in a 500 mL three-necked flask, add 10 g of methyltrichlorosilane, 9 g of dimethyldichlorosilane, 25 g of phenyltrichlorosilane, and 13 g of diphenyldichlorosilane into 150 mL of xylene in sequence, and stir at 60 ° C. A mixture of acetone and excess water was added dropwise, and stirring was continued for 2 h to obtain a silicone resin. Then add the hydrophilic sol-gel silicone prepared above into the silicone resin, stir in a 1000mL three-necked flask at 100°C under normal pressure for 6h, add water to the product and stir for 3h to complete the preparation of the hydrophilic hybrid silicone resin. Self-emulsifying. The resulting hydrophilic silicone resin has good hydrophilic...

Embodiment 2

[0025] Add 4.4g of methyldiethoxysilane, 3.0g of γ-aminopropyltriethoxysilane, 1.2g of Lewis acid catalyst (such as titanium tetrachloride TiCl4) and 36ml of ethanol into a 500mL enamel reaction kettle, and stir at room temperature for 10h to obtain Prepared hydrophilic sol-gel silicone. Then add 53.4ml xylene, 4.24g methyltrichlorosilane, 3.83g dimethyldichlorosilane, 9.95g phenyltrichlorosilane, 5.15g diphenyldichlorosilane in the 500 L enamel reaction kettle successively. Under stirring at 60°C, a mixture of acetone and excess water was added dropwise, and the stirring was continued for 100 min to obtain a silicone resin. Then add the hydrophilic sol-gel silicone prepared above into the silicone resin, stir in a 2000L enamel reactor at 100°C for 6 hours under normal pressure, add water to the product and stir for 5 hours to form a water-based high temperature resistant thermosetting methyl phenyl Silicone.

Embodiment 3

[0027] The water-based high-temperature-resistant thermosetting methylphenyl silicone resin in the above-mentioned example 2 and the methylphenyl silicone resin that has not been graft-modified are tested for related performance. °C / min) thermal weight loss l -m 0 ) / m 0 ×100%, where m 0 and m 1 Respectively, the mass of the film before and after immersion, the water-based high-temperature resistant thermosetting methylphenyl silicone resin has a water absorption rate of 23%, and there is no change after immersion in water at room temperature for 48 hours. The viscosity refers to GB / T 2794-1995, and is measured with a NDJ-7 rotary viscometer at a constant temperature of 25°C. The viscosity of the water-based high-temperature-resistant thermosetting methylphenyl silicone resin is 340mpa s, and the stickiness is 2.78min. Longer, able to meet market requirements. The impact strength of the resin is increased from 35 kg·cm to 50kg·cm, and the hardness reaches the 4H standard. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com