Long glass fiber PP with stable flame-retardant structure and preparation method thereof

A technology with stable structure and long glass fiber, applied in the field of long glass fiber PP, can solve the problems of human and environmental hazards, poor flame retardancy, smoke and toxicity, etc., achieve human and environmental protection, reduce smoke generation, reduce The effect of smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

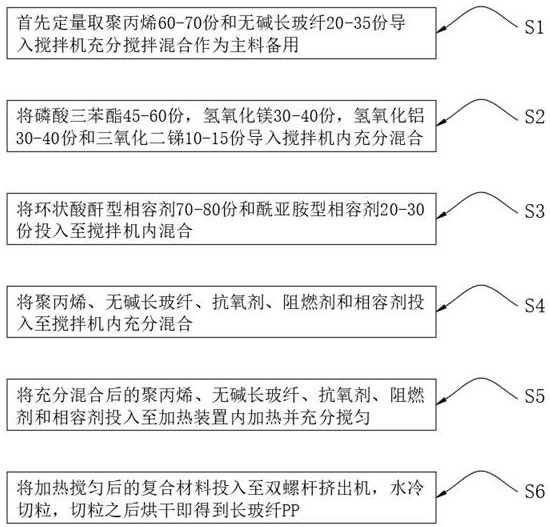

[0025] see figure 1 , the present invention provides a technical solution: a long glass fiber PP with stable flame retardant structure, including the following raw materials by weight: 68 parts of polypropylene, 30 parts of alkali-free long glass fiber, 23 parts of flame retardant, compatible 1.3 parts of antioxidants and 1.3 parts of antioxidants;

[0026] The flame retardant includes the following raw materials by weight: 58 parts of triphenyl phosphate, 38 parts of magnesium hydroxide, 36 parts of aluminum hydroxide and 14 parts of antimony trioxide;

[0027] The antioxidant includes the following raw materials by weight: 88 parts of methyl phenol, 18 parts of diphenylamine, and triphenyl phosphate, magnesium hydroxide, aluminum hydroxide and antimony trioxide are used as flame retardants, and the main part of triphenyl phosphate is used. The advantages are high efficiency, less impact on light stability or light stabilizer, less corrosive in processing and combustion, and...

Embodiment 2

[0042] see figure 1 , The present invention provides a technical solution: a long glass fiber PP with stable flame retardant structure, including the following raw materials by weight: 62 parts of polypropylene, 25 parts of alkali-free long glass fiber, 18 parts of flame retardant, compatible 0.9 parts of antioxidants and 1.2 parts of antioxidants;

[0043] The flame retardant includes the following raw materials by weight: 45 parts of triphenyl phosphate, 30 parts of magnesium hydroxide, 35 parts of aluminum hydroxide and 11 parts of antimony trioxide;

[0044]The antioxidant includes the following raw materials by weight: 85 parts of methyl phenol, 12 parts of diphenylamine, and triphenyl phosphate, magnesium hydroxide, aluminum hydroxide and antimony trioxide are used as flame retardants, and the main part of triphenyl phosphate is used. The advantages are high efficiency, less impact on light stability or light stabilizer, less corrosive in processing and combustion, and ...

Embodiment 3

[0059] see figure 1 , The present invention provides a technical solution: a long glass fiber PP with stable flame retardant structure, including the following raw materials by weight: 60 parts of polypropylene, 20 parts of alkali-free long glass fiber, 15 parts of flame retardant, compatible 0.8 parts of antioxidants and 1.1 parts of antioxidants;

[0060] The flame retardant includes the following raw materials by weight: 45 parts of triphenyl phosphate, 30 parts of magnesium hydroxide, 30 parts of aluminum hydroxide and 10 parts of antimony trioxide;

[0061] The antioxidant includes the following raw materials by weight: 80 parts of methyl phenol, 10 parts of diphenylamine, and triphenyl phosphate, magnesium hydroxide, aluminum hydroxide and antimony trioxide are used as flame retardants, and the main part of triphenyl phosphate is used. The advantages are high efficiency, less impact on light stability or light stabilizer, less corrosiveness in processing and combustion,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com