High-purity hydrogen peroxide preparation method and purifying system

A hydrogen peroxide, high-purity technology, applied in chemical instruments and methods, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, inorganic chemistry, etc. Hydrogen peroxide and other problems, to achieve the effect of slowing down the thermal decomposition rate and the safety of the rectification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

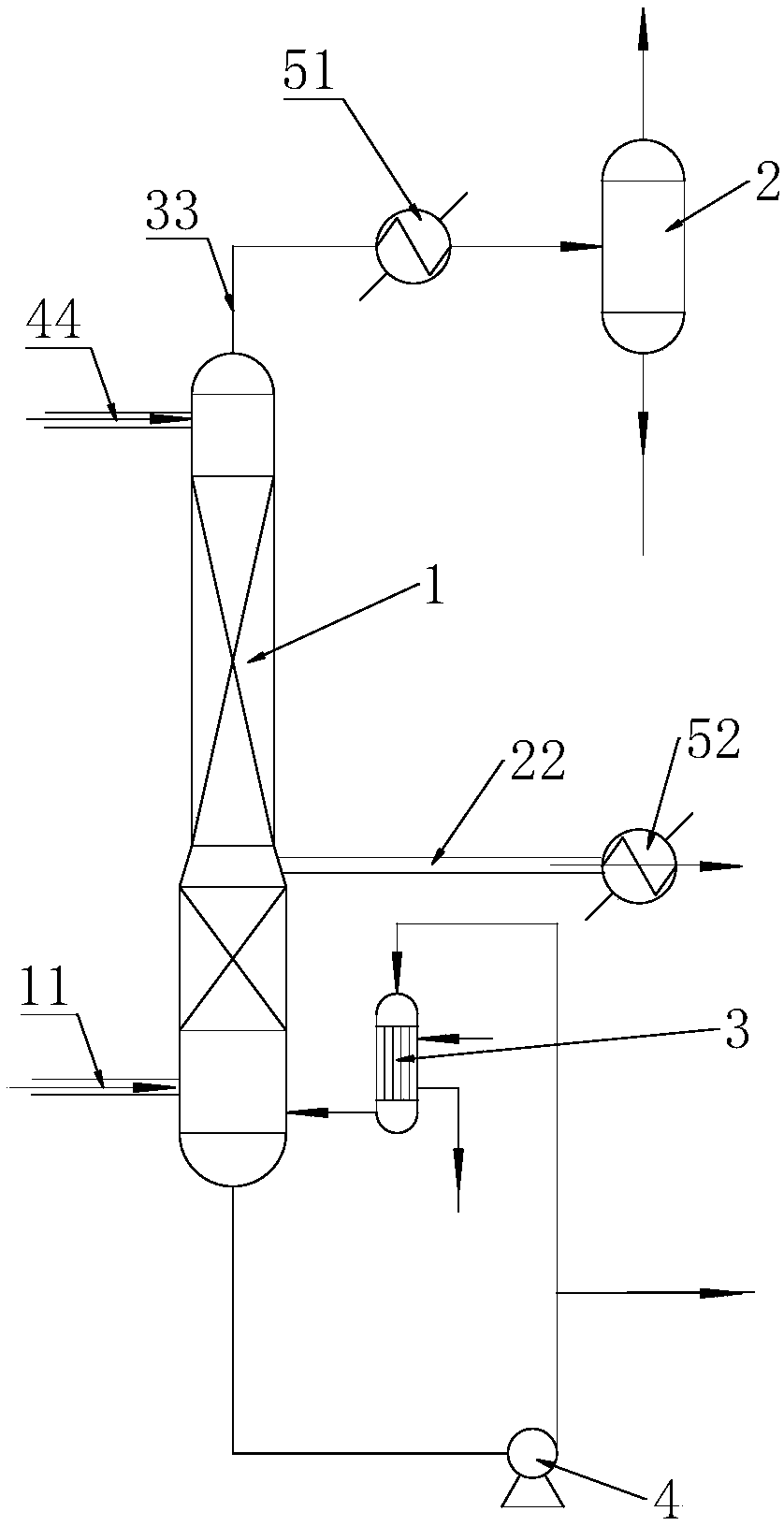

[0035] A method for preparing high-purity hydrogen peroxide includes the following steps:

[0036] a. Turn on the vacuum pump to keep the high vacuum of the rectification system at -0.095Mpa, even if the distillation tower 1 and the reboiler 3 maintain a high vacuum of -0.095Mpa;

[0037] b. Put 2 liters of phosphoric acid from the first pipe 11 into the rectification tower 1, and then pass the circulating pump 4 into the reboiler 3 to circulate and heat to 72°C;

[0038] c. The industrial hydrogen peroxide with a mass fraction of 35% is fed into the rectification tower 1 from the first pipe 11 at a flow rate of 2L / Hr at a uniform speed, and is heated by the reboiler 3 under high vacuum to become steam. After purification by the rectification tower 1, about 35% of high-purity hydrogen peroxide is extracted from the second pipe 22 in the middle and lower part of the rectification tower 1 at a flow rate of 1.9L / Hr; a small amount of hydrogen peroxide is decomposed into water due to hea...

Embodiment 2

[0043] a. Turn on the vacuum pump to keep the rectification system high vacuum at -0.093Mpa, even if the distillation tower 1 and reboiler 3 maintain a high vacuum environment of -0.093Mpa;

[0044] b. Put 2 liters of phosphoric acid from the first pipe 11 into the rectification tower 1, and then pump it into the reboiler 3 through the circulation pump 4 to circulate and heat to 76°C;

[0045] c. The industrial hydrogen peroxide with a mass fraction of 27% is fed into the distillation tower 1 from the first pipe 11 at a constant speed at a flow rate of 2L / Hr. Under high vacuum, it becomes steam after being heated by the reboiler 3, and is purified by the distillation tower 1. The second pipe 22 in the middle and lower part of the rectification tower 1 produces about 27% high-purity hydrogen peroxide at 1.9L / Hr.

[0046] d. The third pipe 33 at the top of the rectification tower 1 produces water at a flow rate of 0.3L / Hr, and supplements the high-purity water with a flow rate of 0.2L / ...

Embodiment 3

[0050] a. Turn on the vacuum pump to keep the rectification system high vacuum at -0.097Mpa, even if the rectification tower 1 and reboiler 3 maintain a high vacuum environment of -0.097Mpa;

[0051] b. Put 2 liters of phosphoric acid from the first pipe 11 into the rectification tower 1, and then pass the circulating pump 4 into the reboiler 3 to circulate and heat to 69°C;

[0052] c. Add 50% industrial hydrogen peroxide at a flow rate of 2L / Hr from the first pipe 11 into the rectification tower 1 at a uniform speed. Under high vacuum, it will become steam after being heated by the reboiler 3 and purified by the rectification tower 1. , From the second pipe 22 in the middle and lower part of the rectification tower 1 at a flow rate of 1.9L / Hr, about 50% of high-purity hydrogen peroxide is produced.

[0053] d. The third pipe 33 at the top of the rectification tower 1 produces water at a flow rate of 0.3L / Hr, and supplements the high-purity water with a flow rate of 0.2L / Hr from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com