A production method for realizing the expansion of the solid phosphorus capacity of clay minerals

A technology of clay minerals and production methods, applied in the field of water pollution control, can solve problems such as secondary pollution, complex and cumbersome preparation procedures, etc., and achieve the effects of high loading capacity, broad application prospects, and significant phosphorus fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

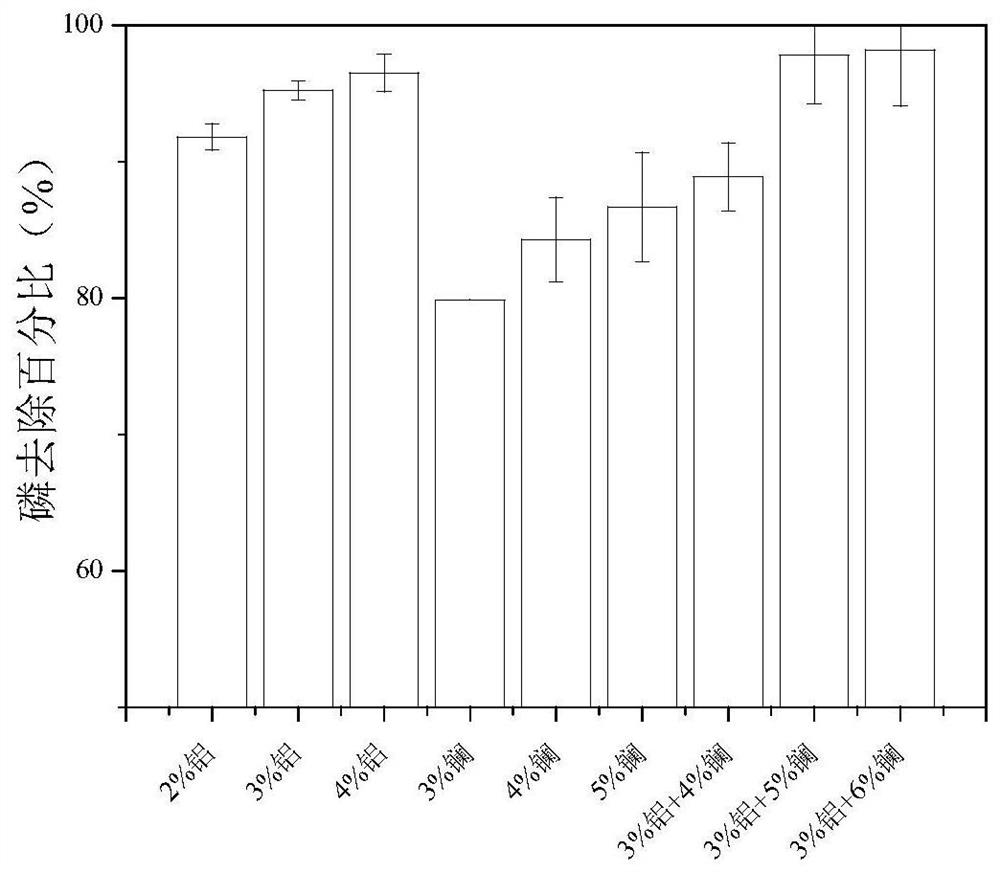

[0030] The attapulgite clay raw ore with a mass content of mineral components greater than or equal to 40% is screened and mechanically crushed into a powder with a sieve mesh greater than or equal to 100 mesh. Mix the powder of attapulgite clay with the mixed solution of polyaluminum chloride and lanthanum chloride according to the solid-to-liquid ratio of 6-9:1, carry out physical mixing for 4 hours, and then use commercially available extrusion equipment to prepare a diameter of 4-6mm , a columnar body phosphorus-locking agent with a length of 2-8mm. Weigh 0.5 g of the above-mentioned phosphorus-locking agent in phosphorus solutions of different solubility, and react for 24 hours to measure the removal efficiency of phosphorus. The result is as figure 1 shown.

Embodiment 2

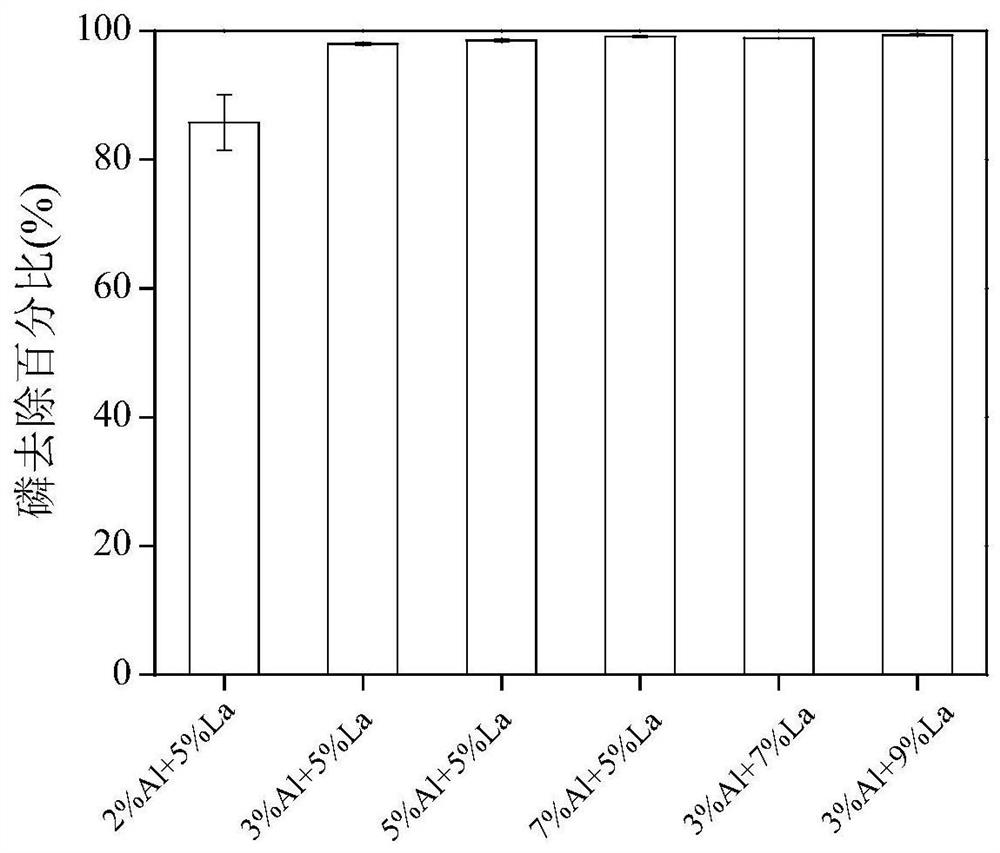

[0032] The raw ore of bentonite, sepiolite or diatomite with a mass content of mineral components greater than or equal to 40% is screened and mechanically crushed into a powder with a sieve mesh greater than or equal to 100 mesh. Mixing the powder of the attapulgite clay with the mixed solution of polyaluminum chloride and lanthanum chloride according to the solid-to-liquid ratio of 9 to 15:1, and the mass fraction of aluminum in the mixed solution and the mixture of the attapulgite clay is 1% , the mass fraction of lanthanum in the mixture of the mixed solution and the attapulgite clay is 2%. After sufficient physical mixing for 8 hours, a columnar phosphor-locking agent with a diameter of 4-6 mm and a length of 2-8 mm was prepared by commercially available extrusion equipment.

Embodiment 3

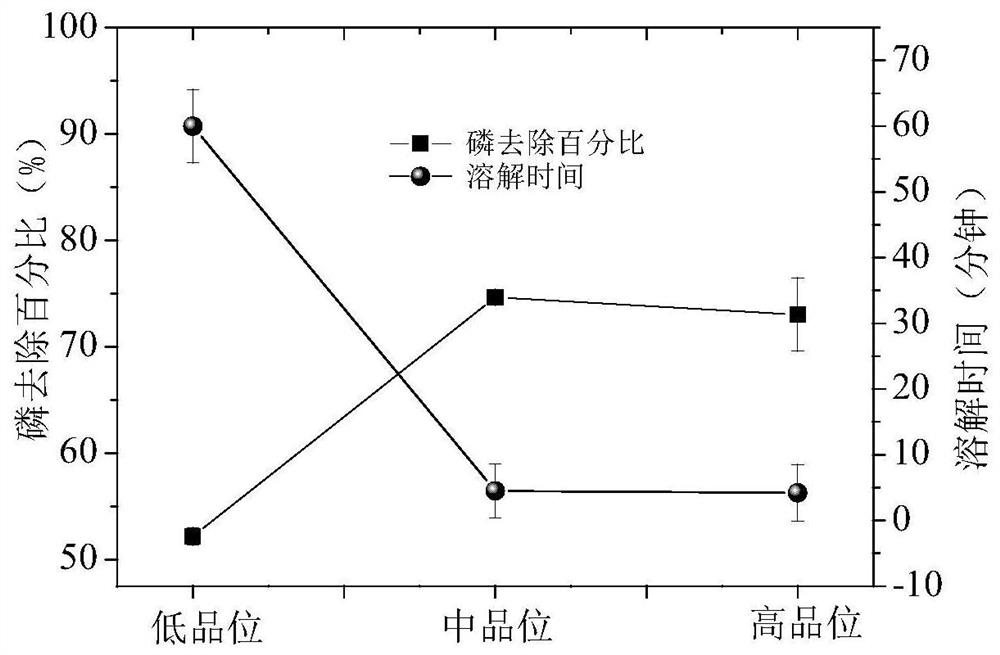

[0034] Attapulgite clays of different grades (low, medium, high) were selected as carriers, and mixed and extruded for physical shaping according to the method described in Example 1. In order to simulate the effect of actual use, 10.0g of different materials were put into 500mL of deionized water, and the dissolution rate and degree of dissolution of the analysis materials in water were observed. The degree of dispersion of the material in the water body determines its phosphorus removal effect in the water body. Phosphorus removal effects of different materials such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com