Preparation method of high activity copper-loaded alumina nanosheet root inhibitor

A nano-alumina, high-activity technology, applied in the field of root inhibitors, can solve the problems of further increase in the specific surface area of copper loading, overflow of metal elements, and reduction of overflow rate, etc., and achieve broad market application prospects, low cost, and restraint The effect of growing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

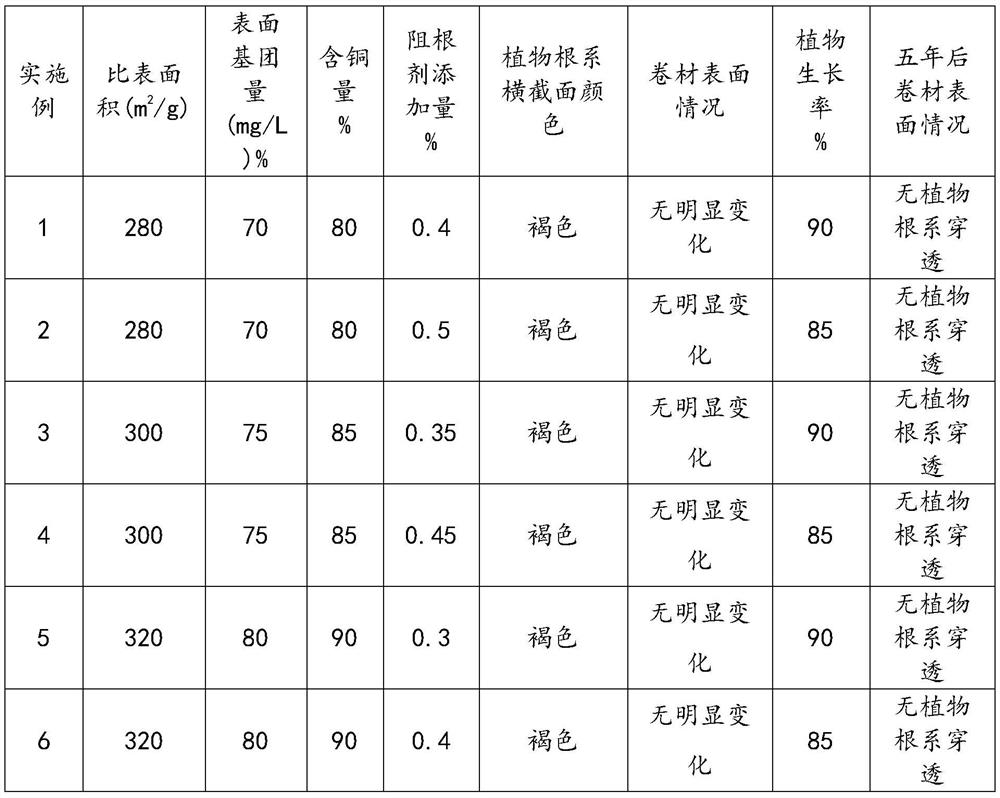

Examples

Embodiment 1

[0018] Embodiment 1: The parts are parts by weight.

[0019] The preparation method of highly active copper-loaded aluminum oxide nanosheet root inhibitor comprises the following steps:

[0020] (1) Solution preparation: adding 10 parts of aluminum chloride solution with a mass fraction of 10% to 50 parts of diethylene glycol, and adding 0.5 parts of a surfactant to mix and stir evenly, adding a mass fraction of 25% concentrated 2 parts of ammonia water continued to stir, and continued at 80° C. for 60 minutes.

[0021] (2) High-temperature combustion: transfer the above mixed solution into a high-temperature reactor, keep it at 180° C. for 5 hours, cool to room temperature, wash the product with absolute ethanol, centrifuge, and finally dry to obtain highly active alumina nanosheets.

[0022] (3) Stirring and centrifugation: Disperse 5 parts of alumina nanosheets in 50 parts of cyclohexane, add 1 part of copper acetylacetonate and 2 parts of sodium borohydride, stir and reac...

Embodiment 2

[0024] Embodiment 2: The parts are parts by weight.

[0025] The preparation method of highly active copper-loaded aluminum oxide nanosheet root inhibitor comprises the following steps:

[0026] (1) Solution preparation: adding 10 parts of aluminum chloride solution with a mass fraction of 10% to 50 parts of diethylene glycol, and adding 0.5 parts of a surfactant to mix and stir evenly, adding a mass fraction of 25% concentrated 2 parts of ammonia water continued to stir, and continued at 80° C. for 60 minutes.

[0027] (2) High-temperature combustion: transfer the above mixed solution into a high-temperature reactor, keep it at 180° C. for 5 hours, cool to room temperature, wash the product with absolute ethanol, centrifuge, and finally dry to obtain highly active alumina nanosheets.

[0028] (3) Stirring and centrifugation: Disperse 5 parts of alumina nanosheets in 50 parts of cyclohexane, add 1 part of copper acetylacetonate and 2 parts of sodium borohydride, stir and reac...

Embodiment 3

[0030] Embodiment 3: The parts are parts by weight.

[0031] The preparation method of highly active copper-loaded aluminum oxide nanosheet root inhibitor comprises the following steps:

[0032] (1) Solution preparation: adding 12 parts of aluminum chloride solution with a mass fraction of 10% to 50 parts of diethylene glycol, and adding 0.7 parts of surfactant to mix and stir evenly, adding a mass fraction of 25% concentrated 3 parts of aqueous ammonia continued to stir, and continued at 80° C. for 90 minutes.

[0033] (2) High-temperature combustion: transfer the above mixed solution into a high-temperature reactor, keep it at 190° C. for 4 hours, cool to room temperature, wash the product with absolute ethanol, centrifuge, and finally dry to obtain high-activity alumina nanosheets.

[0034] (3) Stirring and centrifugation: Disperse 7 parts of alumina nanosheets in 50 parts of cyclohexane, add 2 parts of copper acetylacetonate and 3 parts of sodium borohydride, stir and rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com