Preparation method of shape-controllable magnesium hydroxide with low specific surface area

A technology of magnesium hydroxide and sodium hydroxide, applied in the direction of magnesium hydroxide, etc., can solve the problems such as no magnesium hydroxide morphology, and achieve the effects of controllable morphology, extended flame retardancy, and increased phase boundary area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

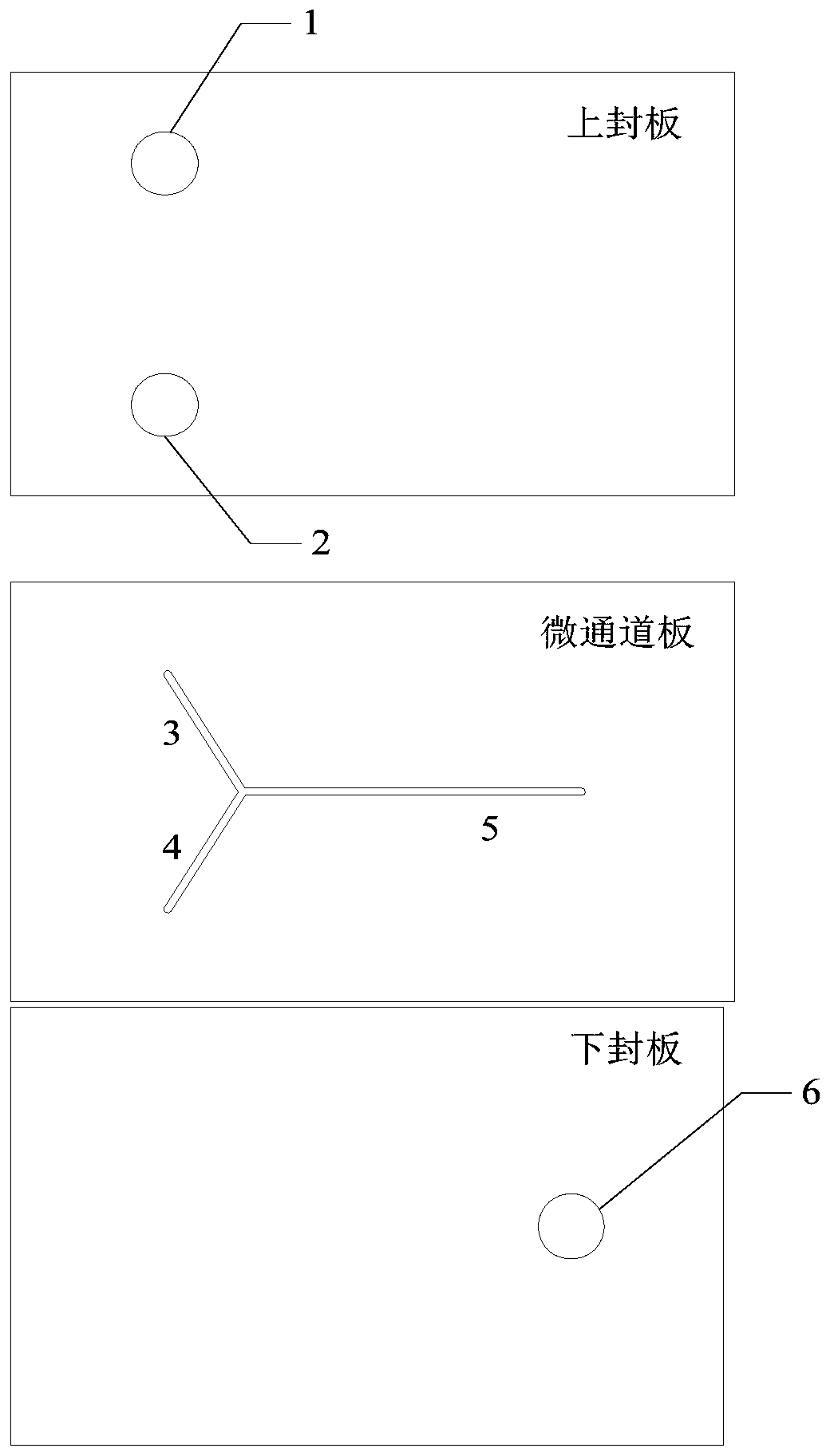

Method used

Image

Examples

Embodiment 1

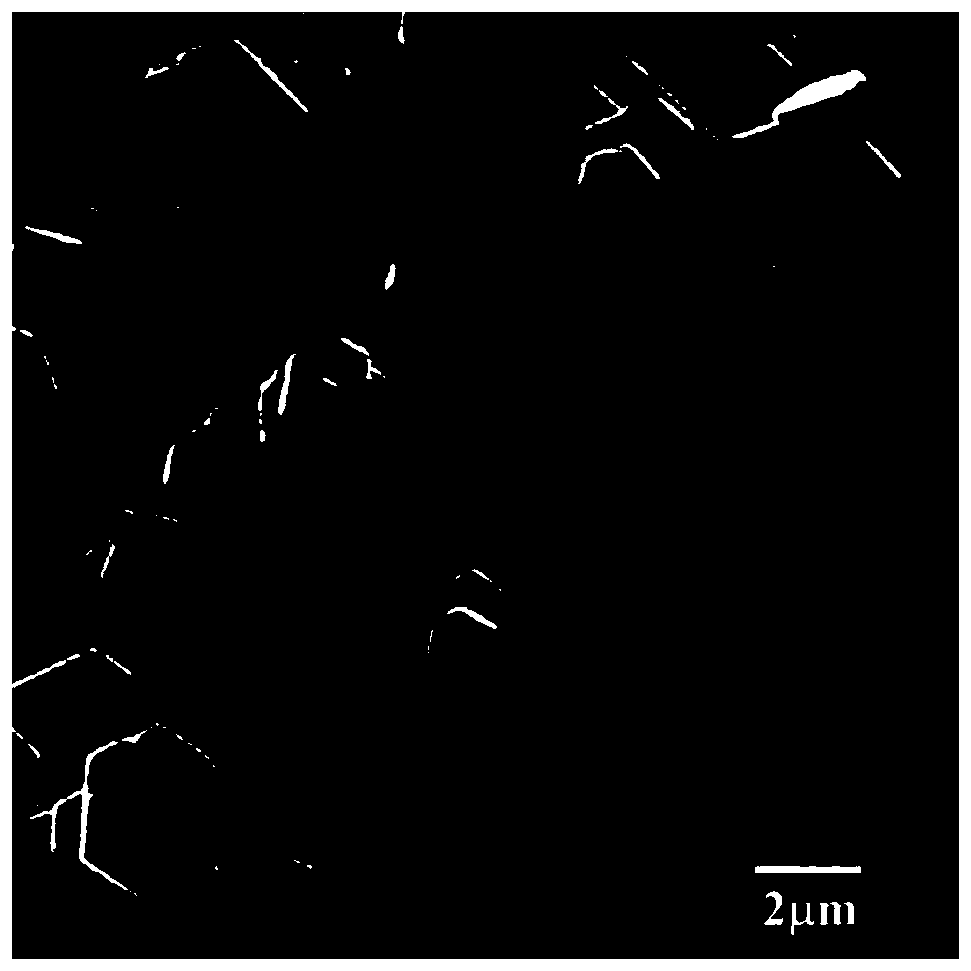

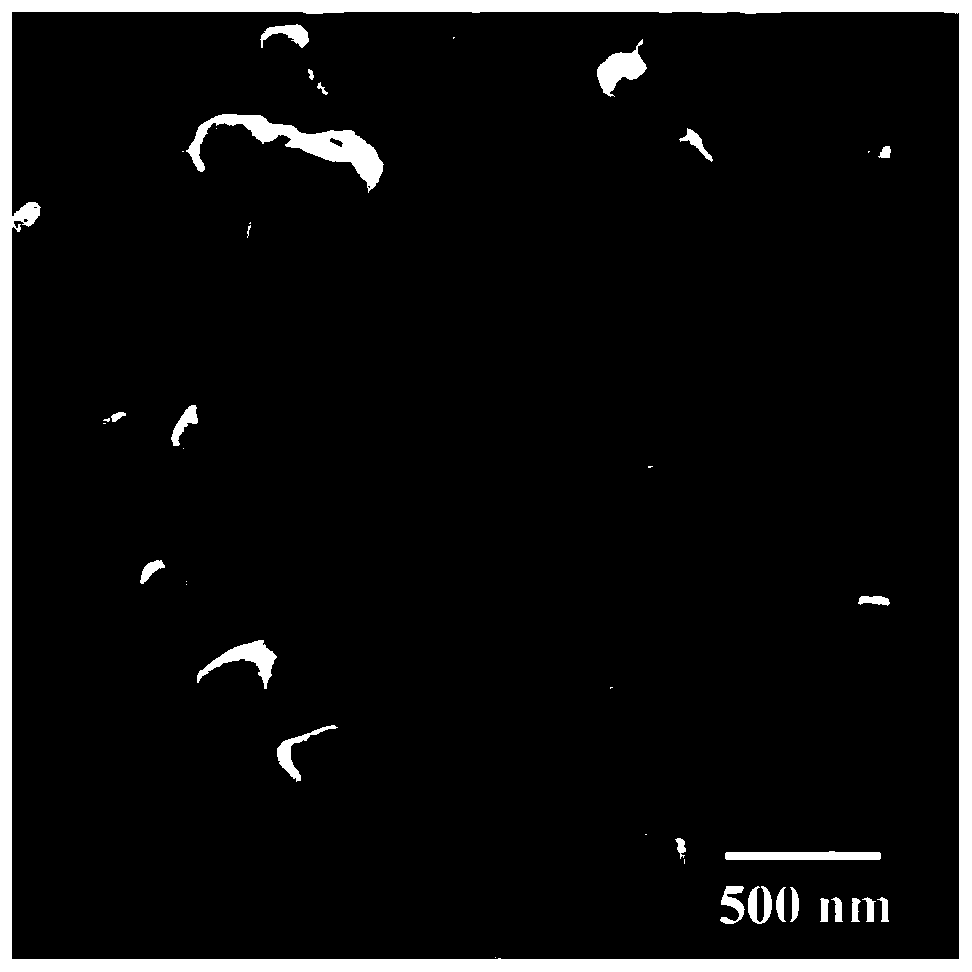

[0033] Configure 1.0mol / L MgCl 2 1L each of aqueous solution and 1.7mol / L NaOH aqueous solution. The above two aqueous solutions all entered the microreactor for contact, mixing and reaction at a flow rate of 100mL / min, n(Mg 2+ ):n(OH -)=1:1.7, the reaction temperature is 60°C. After the reaction slurry flows out from the outlet of the microreactor, it directly enters the hydrothermal synthesis kettle, and performs the first hydrothermal at 180° C., and the hydrothermal time is 4 hours. After the first hydrothermal treatment, the slurry was centrifuged to obtain a filter cake. At this time, the solid content of the filter cake was 18.49 wt.% calculated as magnesium hydroxide. Get 15g of filter cake, add 26.62g of water and 4.65g of NaOH to it, adjust the solid content and sodium hydroxide concentration in the slurry to 6wt.% and 3M in terms of magnesium hydroxide, and carry out the second hydrothermal treatment at 180°C , The water heating time is 4h. After the second hyd...

Embodiment 2

[0035] Configure 1mol / L MgCl 2 1L each of aqueous solution and 2.0mol / L NaOH aqueous solution. The above two aqueous solutions all entered the microreactor for contact, mixing and reaction at a flow rate of 100mL / min, n(Mg 2+ ):n(OH - )=1:2.0, the reaction temperature is 60°C. After the reaction slurry flows out from the outlet of the microreactor, it directly enters the hydrothermal synthesis kettle, and performs the first hydrothermal at 180° C., and the hydrothermal time is 4 hours. After the first hydrothermal treatment, the slurry was centrifuged to obtain a filter cake. At this time, the solid content in the filter cake was 36.33wt.% in terms of magnesium hydroxide. Take 15g of filter cake, add 66.67g of water and 9.14g of NaOH to it, adjust the solid content and sodium hydroxide concentration in the slurry to 6wt.% and 3M in terms of magnesium hydroxide, and carry out the second hydrothermal treatment at 180°C , The water heating time is 4h. After the second hydrot...

Embodiment 3

[0037] Configure 1mol / L MgCl 2 1L each of aqueous solution and 1.2mol / L NaOH aqueous solution. The above two aqueous solutions all entered the microreactor for contact, mixing and reaction at a flow rate of 100mL / min, n(Mg 2+ ):n(OH - )=1:1.7, the reaction temperature is 60°C. After the reaction slurry flows out from the outlet of the microreactor, it directly enters the hydrothermal synthesis kettle, and performs the first hydrothermal at 200° C., and the hydrothermal time is 4 hours. After the first hydrothermal treatment, the slurry was centrifuged to obtain a filter cake. At this time, the solid content of the filter cake was 18.49 wt.% calculated as magnesium hydroxide. Take 15g of filter cake, add 30.22g of water and 5.05g of NaOH therein, adjust the solid content and sodium hydroxide concentration in the slurry to 6wt.% and 3M in terms of magnesium hydroxide, and carry out the second hydrothermal treatment at 220°C , The water heating time is 6h. After the second h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com