Preparation method of kudzuvine root essence electuary

A technology for essences and granules, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve the problems of reducing production processes, low production efficiency, and cumbersome preparation processes, and achieves reduction of production processes. The effect of re-production and high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

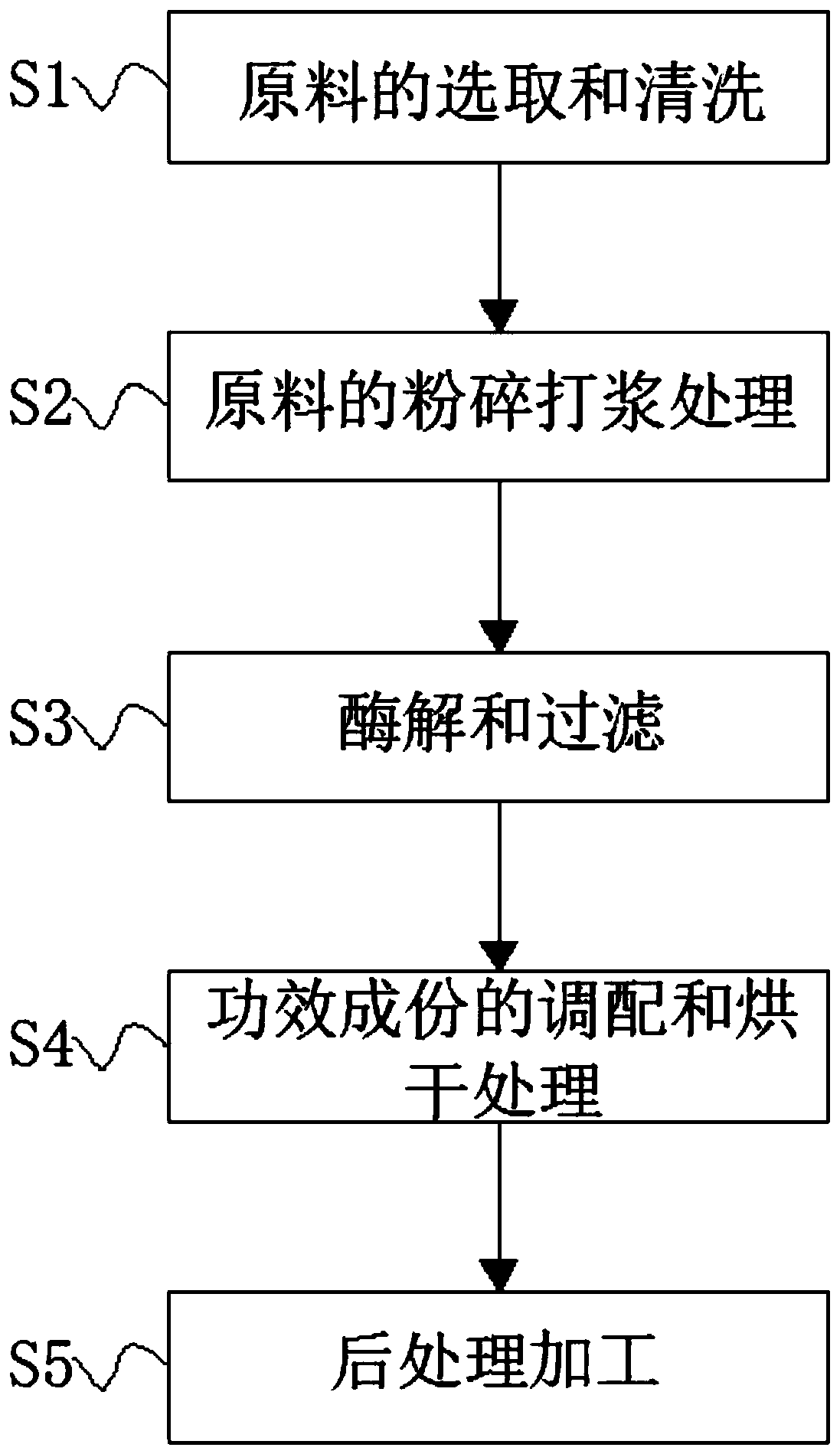

Method used

Image

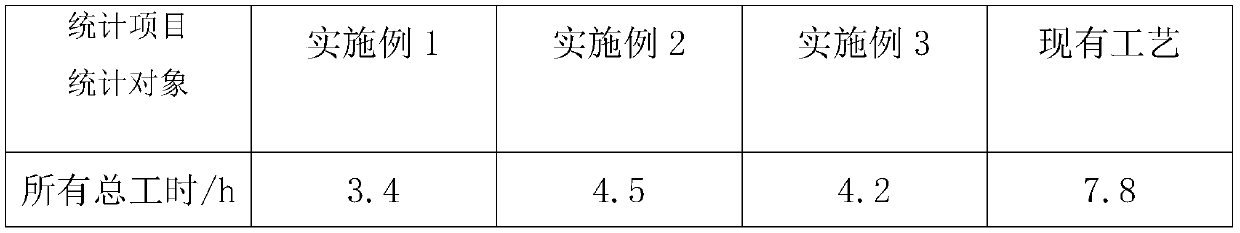

Examples

Embodiment 1

[0027] S1. Selection and cleaning of raw materials: firstly select the kudzu root grown in that year as the raw material, and then wash it with clean water 3 times to clean the large impurities on the surface of the selected kudzu root raw material, and then put the selected kudzu root raw material into the ultrasonic cleaning equipment for cleaning Ultrasonic cleaning for 17 minutes, so that small impurities fall off the surface of the kudzu root raw material. The selected kudzu root raw material is the fresh and tender kudzu root that grew in the same year without pests and damage;

[0028] S2. Crushing and beating treatment of raw materials: Pour the kudzu root raw material cleaned in step S1 into the pulverization and beating equipment, first squeeze and crush the kudzu root raw material through the crushing roller in the pulverization and beating equipment, and the crushed raw material and juice will pass through the guide The material plate enters the beating chamber, and...

Embodiment 2

[0033] S1. Selection and cleaning of raw materials: firstly select the kudzu root that grew in that year as the raw material, then wash it twice with clean water to clean the large impurities on the surface of the selected kudzu root raw material, and then put the selected kudzu root raw material into the ultrasonic cleaning equipment for cleaning Ultrasonic cleaning for 15 minutes to make small impurities fall off the surface of the kudzu root raw material. The selected kudzu root raw material is the fresh and tender kudzu root that grew in the same year without pests and damage;

[0034] S2. Crushing and beating treatment of raw materials: Pour the kudzu root raw material cleaned in step S1 into the pulverization and beating equipment, first squeeze and crush the kudzu root raw material through the crushing roller in the pulverization and beating equipment, and the crushed raw material and juice will pass through the guide The material plate enters the beating chamber, and wh...

Embodiment 3

[0039] S1. Selection and cleaning of raw materials: firstly select the kudzu root grown in that year as the raw material, and then wash it with clean water 3 times to clean the large impurities on the surface of the selected kudzu root raw material, and then put the selected kudzu root raw material into the ultrasonic cleaning equipment for cleaning Ultrasonic cleaning for 20 minutes to make small impurities fall off the surface of the kudzu root raw material. The selected kudzu root raw material is the fresh and tender kudzu root that grew in the same year without pests and damage;

[0040] S2. Crushing and beating treatment of raw materials: Pour the kudzu root raw material cleaned in step S1 into the pulverization and beating equipment, first squeeze and crush the kudzu root raw material through the crushing roller in the pulverization and beating equipment, and the crushed raw material and juice will pass through the guide The material plate enters the beating chamber, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com