Memristor with double resistance change layer and preparation method

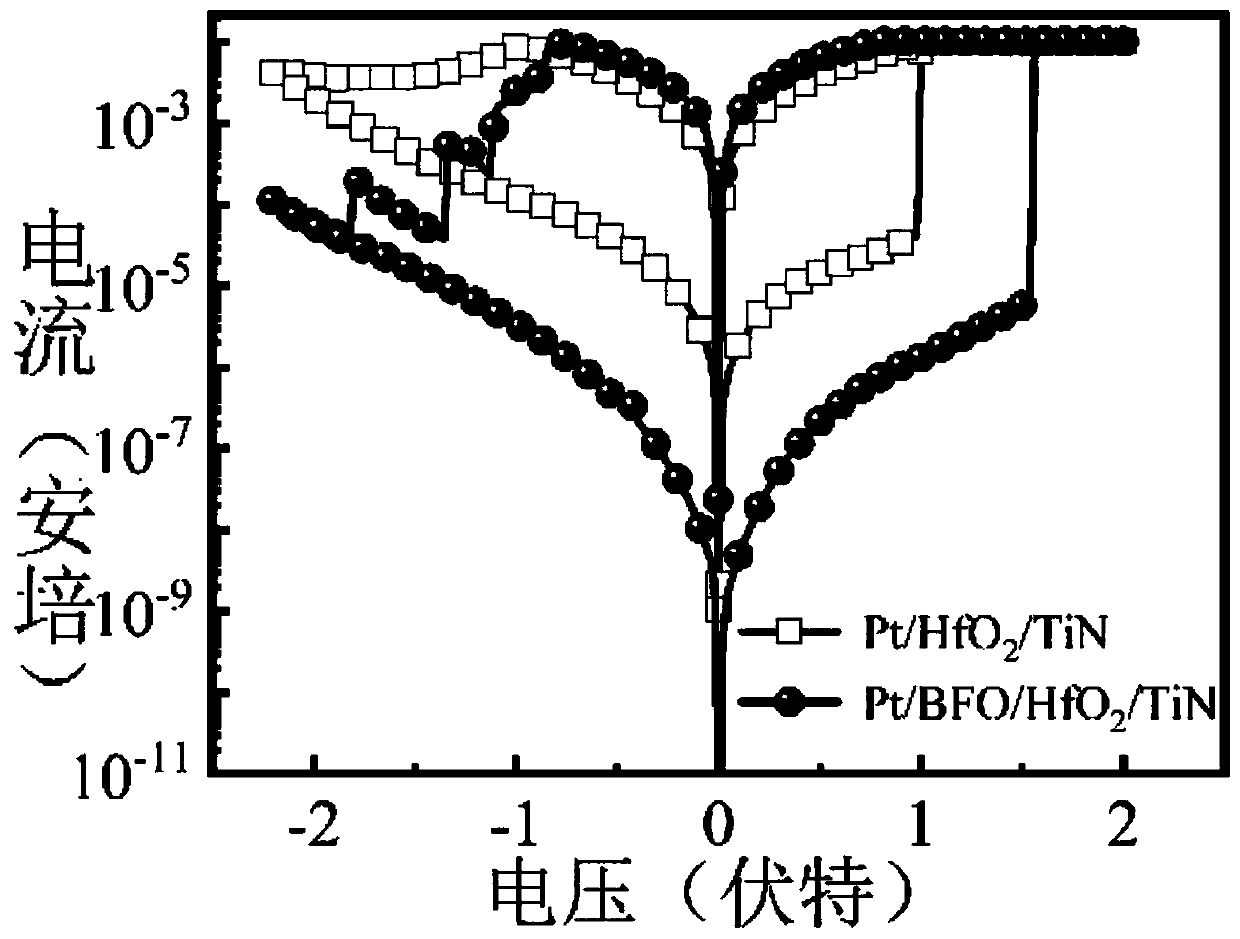

A technology of resistive variable layer and memristor, which is applied in the direction of electrical components, etc., can solve the problems of uneven distribution of high and low resistance states, weak photoferroelectric response, and poor durability, and achieve good durability, long retention time, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

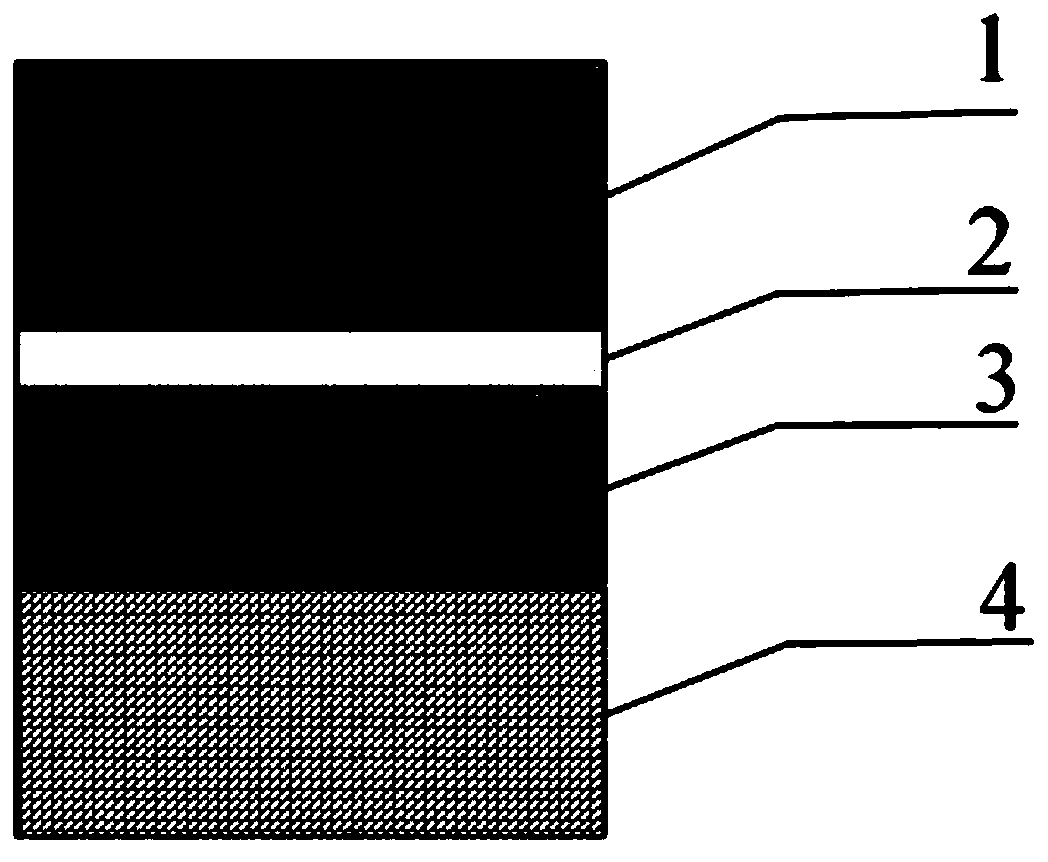

[0038] A memristor, which is mainly composed of a silicon oxide substrate, a bottom electrode, a first resistive layer, a second resistive layer and a top electrode, wherein the material of the bottom electrode is titanium nitride (TiN) with a thickness of 200nm, The material of the first resistive layer is hafnium oxide (HfO 2 ), the material of the second resistive switch layer is bismuth ferrite (BFO) with a thickness of 8nm and 2nm respectively, and the material of the top electrode is platinum (Pt) with a thickness of 200nm.

[0039] Step 1, cleaning the silicon oxide wafer

[0040] Place the silicon oxide wafer in an ultrasonic instrument, and use acetone, absolute ethanol, and deionized water to sonicate for 15 minutes respectively;

[0041] Step 2, prepare the bottom electrode

[0042] Prepare a layer of titanium nitride bottom electrode on the silicon substrate by magnetron sputtering method, and the vacuum degree of magnetron sputtering is less than 10 - 4 Pa, th...

Embodiment 2

[0052] A memristor, which is mainly composed of a silicon oxide substrate, a bottom electrode, a first resistive layer, a second resistive layer and a top electrode, wherein the material of the bottom electrode is titanium nitride (TiN) with a thickness of 200nm, The material of the first resistive layer is hafnium oxide (HfO 2 ), the material of the second resistive switch layer is bismuth ferrite (BFO) with a thickness of 8nm and 1nm respectively, and the material of the top electrode is platinum (Pt) with a thickness of 200nm.

[0053] Step 1, cleaning the silicon oxide wafer

[0054] Place the silicon oxide wafer in an ultrasonic instrument, and use acetone, absolute ethanol, and deionized water to sonicate for 15 minutes respectively;

[0055] Step 2, prepare the bottom electrode

[0056] Prepare a layer of titanium nitride bottom electrode on the silicon substrate by magnetron sputtering method, and the vacuum degree of magnetron sputtering is less than 10 - 4 Pa, th...

Embodiment 3

[0066] A memristor, which is mainly composed of a silicon oxide substrate, a bottom electrode, a first resistive layer, a second resistive layer and a top electrode, wherein the material of the bottom electrode is titanium nitride (TiN) with a thickness of 200nm, The material of the first resistive layer is hafnium oxide (HfO 2 ), the material of the second resistive switch layer is bismuth ferrite (BFO) with a thickness of 8nm and 9nm respectively, and the material of the top electrode is platinum (Pt) with a thickness of 200nm.

[0067] Step 1, cleaning the silicon oxide wafer

[0068] Place the silicon oxide wafer in an ultrasonic instrument, and use acetone, absolute ethanol, and deionized water to sonicate for 15 minutes respectively;

[0069] Step 2, prepare the bottom electrode

[0070] Prepare a layer of titanium nitride bottom electrode on the silicon substrate by magnetron sputtering method, and the vacuum degree of magnetron sputtering is less than 10 - 4 Pa, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com