Environmental-friendly harmless high-flame-retardant polymer material for plugging water and reinforcing coal and rock masses in coal mines and preparation method thereof

A polymer material and high flame-retardant technology, applied in the field of polyurethane materials, can solve problems such as environmental pollution and flame-retardant performance degradation, and achieve the effects of durable flame-retardant performance, enhanced rigidity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

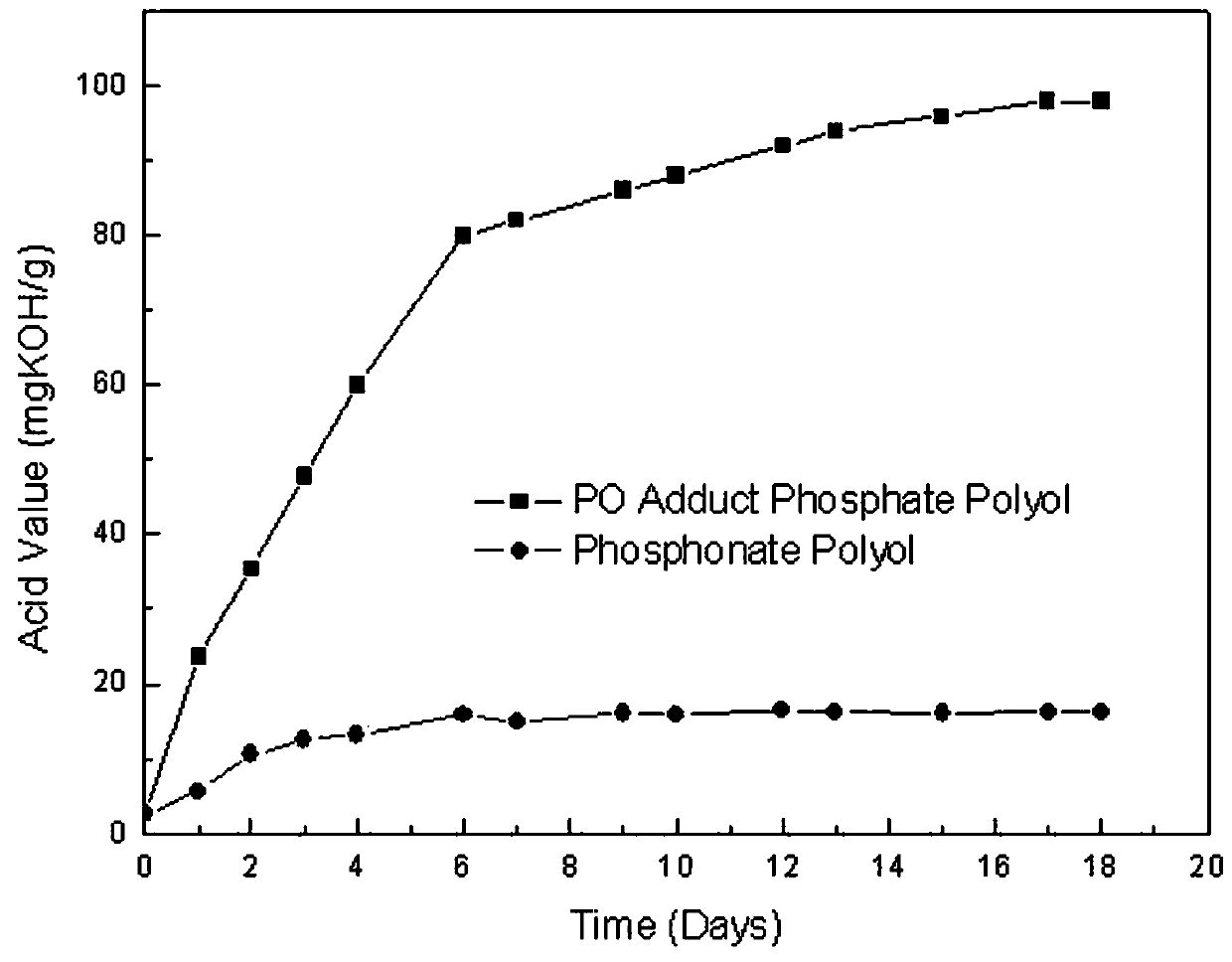

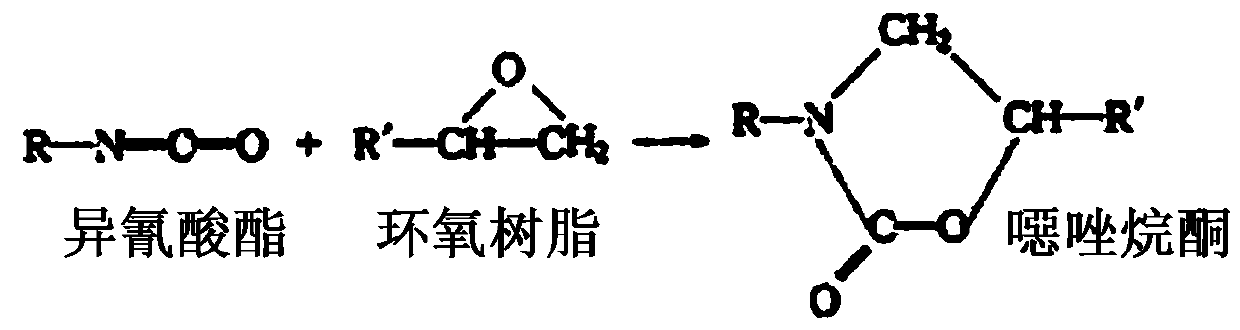

[0030] Example 1: The preparation method of phenolic phosphonate polyols is: 100g triphenyl phosphite, 50g DEG, 0.1g 2,6-di-tert-butyl p-cresol and 0.01g tetrabutyl titanate Ratio feeding in an autoclave to ensure the nitrogen environment in the autoclave, react at 135°C for 6 hours, cool down to 85°C, add 15g of formaldehyde, the reaction is exothermic, the temperature gradually rises to 105°C, and continue to react at 100°C for 4 hours. Remove unreacted formaldehyde, add 15g epoxy resin DYD-127, add ethylene oxide until the acid value drops below 5mgKOH / g, vacuum remove unreacted ethylene oxide, add 25g epoxy resin DYD-127 get the product. Phosphonate polyols with a phosphorus content of 4.88% were obtained after adsorption, filtration, distillation and other processes, and no hydrolysis was found during storage.

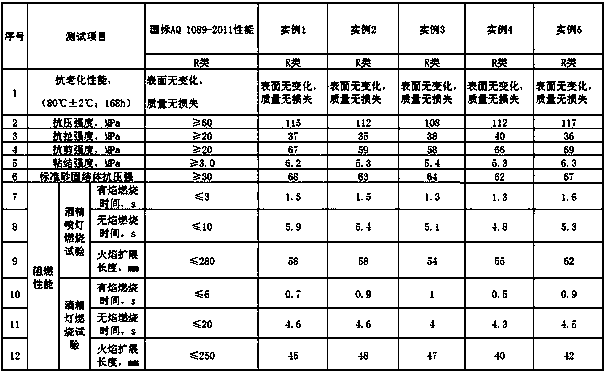

[0031] An environmentally friendly, harmless and highly flame-retardant polymer material for coal mine water plugging and reinforcement of coal rock mass. The ra...

Embodiment 2

[0032] Example 2: The preparation method of phenolic phosphonate polyols is: 150g triphenyl phosphite, 45g DEG, 0.1g 2,6-di-tert-butyl p-cresol and 0.01g tetrabutyl titanate Ratio feed in an autoclave to ensure the nitrogen environment in the autoclave, react at 135°C for 6 hours, cool down to 85°C, add 30g of formaldehyde, the reaction exotherms, the temperature gradually rises to 105°C, keep 100°C and continue to react for 4 hours. Remove unreacted formaldehyde, add 20g epoxy resin DYD-127, add ethylene oxide until the acid value drops below 5mgKOH / g, vacuum remove unreacted ethylene oxide, add 30g epoxy resin DYD-127 get the product. Phosphonate polyols with a phosphorus content of 5.45% were obtained after adsorption, filtration, distillation and other processes, and no hydrolysis was found during the storage period.

[0033] An environmentally friendly, harmless and highly flame-retardant polymer material for coal mine water plugging and reinforcement of coal rock mass. ...

Embodiment 3

[0034] Example 3: The preparation method of phenolic phosphonate polyols is: 170g triphenyl phosphite, 55g DEG, 0.1g 2,6-di-tert-butyl p-cresol and 0.01g tetrabutyl titanate Proportionally feed in an autoclave to ensure the nitrogen environment in the autoclave, react at 135°C for 6 hours, cool down to 85°C, add 35g of formaldehyde, the reaction is exothermic, the temperature gradually rises to 105°C, and continue to react at 100°C for 4 hours. Remove unreacted formaldehyde, add 40g epoxy resin DYD-127, add ethylene oxide until the acid value drops below 5mgKOH / g, vacuum remove unreacted ethylene oxide, add 35g epoxy resin DYD-127 get the product. Phosphonate polyols with a phosphorus content of 5.07% were obtained after adsorption, filtration, distillation and other processes, and no hydrolysis was found during the storage period.

[0035] An environmentally friendly, harmless and highly flame-retardant polymer material for coal mine water plugging and reinforcement of coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com