Admixture for marine engineering concrete and preparation method of admixture

A marine engineering and concrete technology, which is applied in the field of marine engineering concrete admixtures and its preparation, can solve the problems that marine engineering concrete cannot achieve marine engineering performance, poor adaptability of cement varieties, and affect quality uniformity, etc., to reduce the direct contact area , Reduce water consumption and increase density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

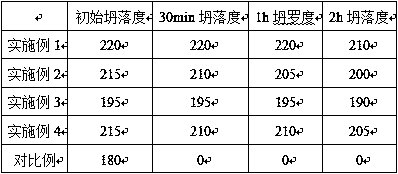

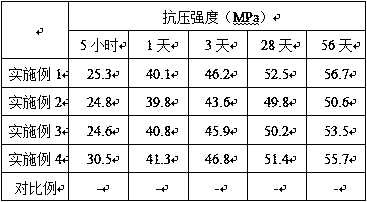

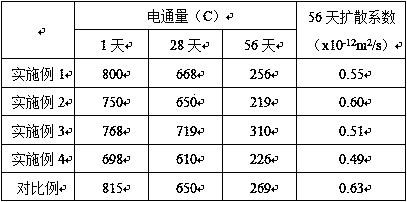

Embodiment 1

[0056] An admixture for marine engineering concrete, comprising the following raw materials in parts by weight: 100 parts of water reducing agent; 0.5 part of tetramethylammonium iodide; 1 part of sodium ethylate; 3 parts of polyacrylamide; 30 parts of surfactant; 15 parts of agent; 30 parts of expansion agent; 3 parts of retarder; 6 parts of defoamer; 50 parts of water.

[0057] The preparation method of the admixture for marine engineering concrete is as follows:

[0058] (1) Add tetramethylammonium iodide, sodium ethoxide and polyacrylamide into the mixing water according to parts by weight, stir and dissolve, put them into a grinder and grind them evenly, then put them into a mixer and stir them for 10 minutes to obtain solution A;

[0059] (2) Put solution A in a constant temperature water bath, add water reducer, surfactant, rust inhibitor, expansion agent, retarder, defoamer in parts by weight, and stir it evenly. The temperature of the water bath is 35°C to obtain an ...

Embodiment 2

[0061] An admixture for marine engineering concrete, comprising the following raw materials in parts by weight: 150 parts of water reducing agent; 1 part of tetramethylammonium iodide; 5 parts of sodium ethylate; 5 parts of polyacrylamide; 50 parts of surfactant; 20 parts of agent; 50 parts of expansion agent; 5 parts of retarder; 10 parts of defoamer; 80 parts of water.

[0062] The preparation method of the admixture for marine engineering concrete is as follows:

[0063] (1) Add tetramethylammonium iodide, sodium ethoxide and polyacrylamide into the mixing water according to the parts by weight, stir and dissolve, put them into a grinder and grind them evenly, then put them into a mixer and stir for 13 minutes to obtain solution A;

[0064] (2) Put solution A in a constant temperature water bath, add water reducer, surfactant, rust inhibitor, expansion agent, retarder, defoamer in parts by weight, and stir it evenly. The temperature of the water bath is 38°C to obtain an a...

Embodiment 3

[0066] An admixture for marine engineering concrete, comprising the following raw materials in parts by weight: 125 parts of water reducing agent; 0.7 part of tetramethylammonium iodide; 3 parts of sodium ethylate; 4 parts of polyacrylamide; 40 parts of surfactant; 17 parts of agent; 40 parts of expansion agent; 4 parts of retarder; 8 parts of defoamer; 75 parts of water.

[0067] The preparation method of the admixture for marine engineering concrete is as follows:

[0068] (1) Add tetramethylammonium iodide, sodium ethoxide and polyacrylamide into the mixing water according to parts by weight, stir and dissolve, put them into a grinder and grind them evenly, then put them into a mixer and stir them for 15 minutes to obtain solution A;

[0069] (2) Put solution A in a constant temperature water bath, add water reducer, surfactant, rust inhibitor, expansion agent, retarder, defoamer in parts by weight, and stir it evenly. The temperature of the water bath is 40°C to obtain an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com