Edge trimming device and method for lithium battery production

A lithium battery and edge trimming technology, applied in metal processing and other directions, can solve the problems of complicated operation and inconvenient fixing of lithium batteries, and achieve the effect of simple operation, avoiding potential safety hazards and facilitating fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

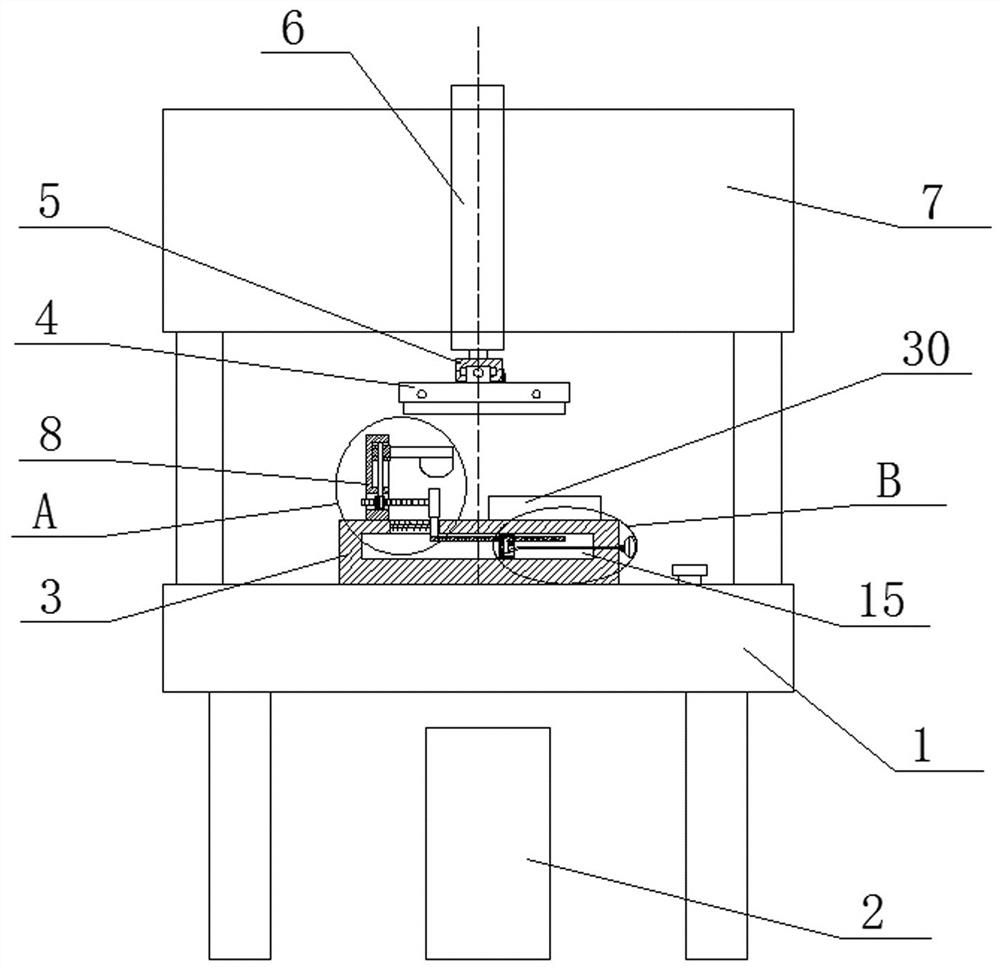

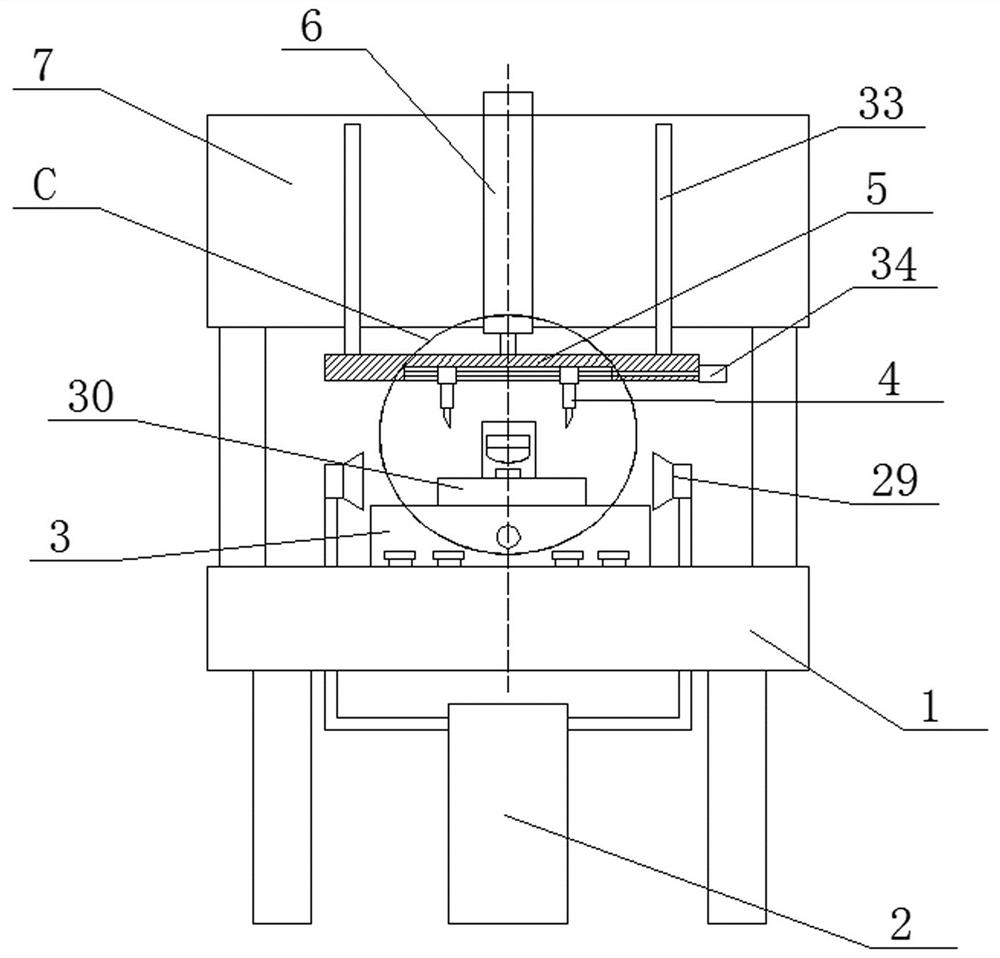

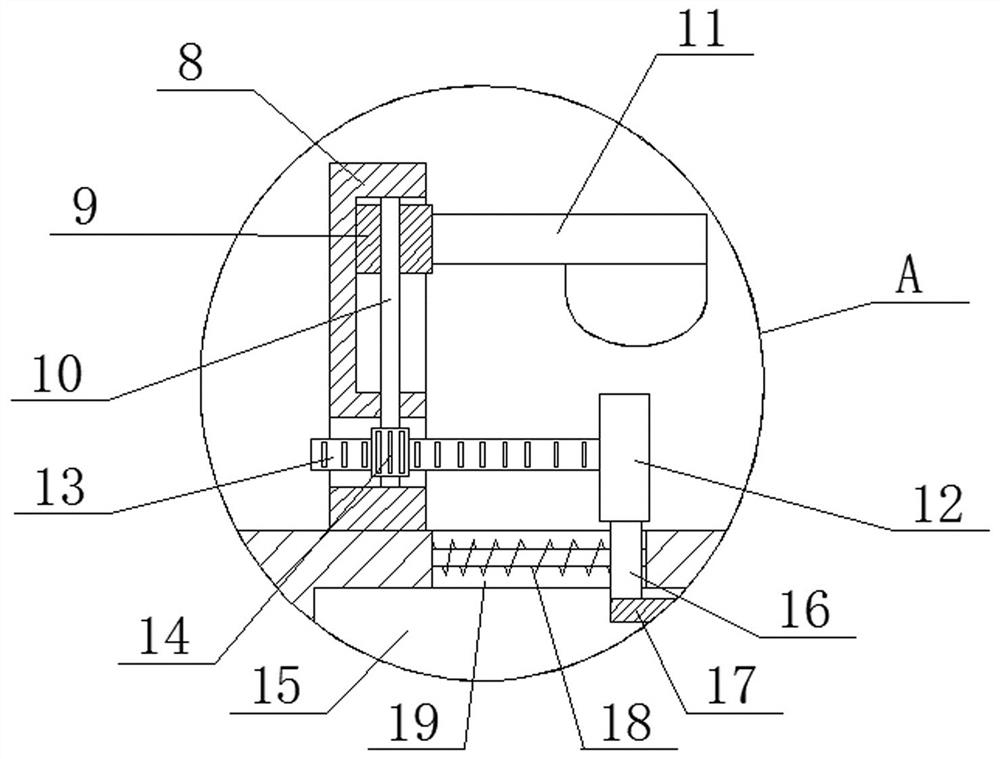

[0045] refer to Figure 1-6 , an edge trimming device for lithium battery production, comprising a console 1, a top frame 7 is arranged on the top of the console 1, a hydraulic push rod 6 is arranged on the top frame 7, and two output shafts of the hydraulic push rod 6 are installed Knives 4, a vacuum cleaner 2 is arranged under the operating table 1, a cutting table 3 is arranged on the top of the operating table 1, a lithium battery 30 is placed on the cutting table 3, and two dust suction cylinders 29 are connected to the vacuum cleaner 2, and two dust suction The cylinders 29 are respectively located on both sides of the cutting table 3, the top of the cutting table 3 is provided with a vertical plate 8, a pressure plate 11 is slidably installed on one side of the vertical plate 8, and a force plate 12 is movably installed on the vertical plate 8, and the force plate 12 cooperates with the pressure plate 11, and two dust suction cylinders 29 are respectively positioned at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com