Method for improving corrosion resistance of welding joint between aluminum plate and steel plate

A welded joint and corrosion-resistant technology, which is applied in welding equipment, cold-pressed connections, connected components, etc., can solve problems affecting the safety and service life of welded components, galvanic corrosion, and reduce joint performance, etc., to achieve control of intermetallic compound content , Improve corrosion resistance, improve the effect of joint performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

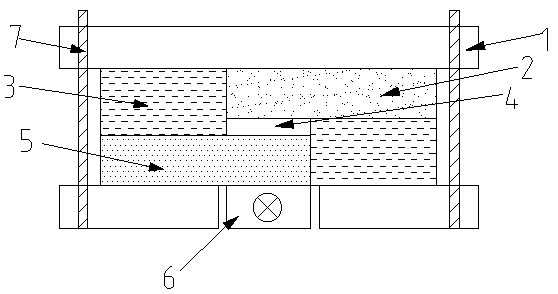

[0038] The dimensions of aluminum plate and stainless steel plate are both 75 mm×20 mm×1.5 mm, and the specific steps of electromagnetic pulse welding are as follows:

[0039](1) Grind the surface of the steel plate to be welded with sandpaper until the surface is bright, and clean it with alcohol, then scrub it with acetone and dry it naturally, so as to remove the oil and impurities on the surface of the welding material to be welded;

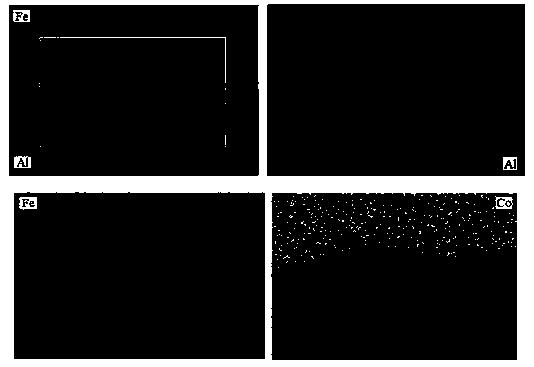

[0040] (2) The treated steel plate is plated with a layer of cobalt on the surface to be welded by electroplating, and the cobalt-plated steel plate obtained is ready for use;

[0041] (3) Assemble the prepared aluminum plate and steel plate on the welding fixture, use the aluminum plate as the double plate, and the steel plate as the base plate, adjust the weld gap and lap length through the insulating backing plate, where the lap gap is 2.0 mm, and the lap joint The length is 20 mm, for electromagnetic pulse lap welding of aluminum plate / st...

Embodiment 2

[0047] The dimensions of aluminum plate and stainless steel plate are both 75 mm × 20 mm × 2 mm, and the specific steps of electromagnetic pulse welding are as follows:

[0048] (1) Grind the surface of the steel plate to be welded with sandpaper until the surface is bright, and clean it with alcohol, then scrub it with acetone and dry it naturally, so as to remove the oil and impurities on the surface of the welding material to be welded;

[0049] (2) Apply electroplating to the treated steel plate to coat a layer of cobalt on the surface to be welded, and then perform the following operations on the obtained cobalt-plated steel plate;

[0050] (3) Assemble the prepared aluminum plate and steel plate on the welding fixture. The aluminum plate is used as the double plate and the steel plate is used as the base plate. The weld gap and lap length are adjusted through the insulating backing plate. The lap gap is 1.8 mm, and the lap joint Length 15 mm, for electromagnetic pulse la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com