A steel slag modifier with structure grinding aid and surface wrapping effect and preparation method thereof

A modifier and steel slag technology, applied in chemical instruments and methods, other chemical processes, grain processing, etc., can solve the problems of poor grindability and poor dispersibility of steel slag, and achieve reduced grinding energy consumption, low cost, and obvious economy Effects of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

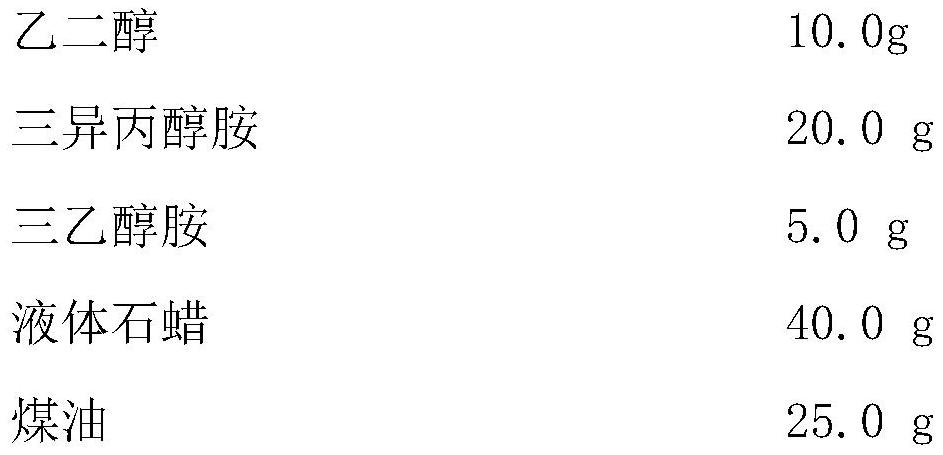

[0024] A steel slag modifier with structural grinding aid and surface wrapping effect, made of raw materials of the following quality:

[0025]

[0026] A preparation method of a steel slag modifier having the functions of structural grinding aid and surface wrapping, comprising the following steps:

[0027] 1) After mixing the above-mentioned ethylene glycol, triisopropanolamine and triethanolamine, use a constant temperature magnetic stirrer to stir at a temperature of 35°C at a speed of 900r / min for 80min to obtain ethylene glycol-triisopropanolamine - Triethanolamine mixture.

[0028] 2) After mixing the above-mentioned liquid paraffin and kerosene, stir with a constant temperature magnetic stirrer at a temperature of 40° C. at a speed of 600 r / min for 110 min to obtain a liquid paraffin-kerosene mixture.

[0029] 3) After mixing the ethylene glycol-triisopropanolamine-triethanolamine mixed solution obtained above with the liquid paraffin-kerosene mixed solution, use a...

Embodiment 2

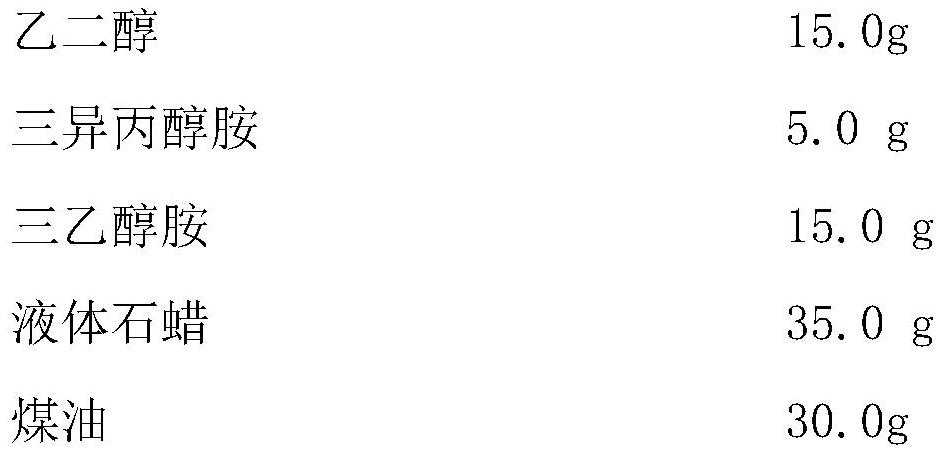

[0031] A steel slag modifier with structural grinding aid and surface wrapping effect, made of raw materials of the following quality:

[0032]

[0033] A preparation method of a steel slag modifier having the functions of structural grinding aid and surface wrapping, comprising the following steps:

[0034] 1) After mixing the above-mentioned ethylene glycol, triisopropanolamine and triethanolamine, use a constant temperature magnetic stirrer to stir at a temperature of 40°C at a speed of 700r / min for 120min to obtain ethylene glycol-triisopropanolamine - Triethanolamine mixture.

[0035] 2) After mixing the above-mentioned liquid paraffin and kerosene, stir with a constant temperature magnetic stirrer at a temperature of 30° C. at a speed of 900 r / min for 90 min to obtain a liquid paraffin-kerosene mixture.

[0036] 3) Finally, after mixing the ethylene glycol-triisopropanolamine-triethanolamine mixed solution obtained above with the liquid paraffin-kerosene mixed soluti...

Embodiment 3

[0038] A steel slag modifier with structural grinding aid and surface wrapping effect, made of raw materials of the following quality:

[0039]

[0040] A preparation method of a steel slag modifier having the functions of structural grinding aid and surface wrapping, comprising the following steps:

[0041] 1) After mixing the above-mentioned ethylene glycol, triisopropanolamine and triethanolamine, use a constant temperature magnetic stirrer to stir at a temperature of 30°C at a speed of 500r / min for 100min to obtain ethylene glycol-triisopropanolamine - Triethanolamine mixture.

[0042] 2) After mixing the above-mentioned liquid paraffin and kerosene, stir with a constant temperature magnetic stirrer at a temperature of 35° C. at a speed of 1000 r / min for 70 min to obtain a liquid paraffin-kerosene mixture.

[0043] 3) After mixing the ethylene glycol-triisopropanolamine-triethanolamine mixed solution obtained above with the liquid paraffin-kerosene mixed solution, use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com