Microfiber black tea powder instant tea and preparation method thereof

A technology of microfiber and black tea powder, applied in the direction of tea treatment before extraction, can solve the problem of insufficient release of nutrients, and achieve the effects of enhanced silkiness, high stability and small fiber fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

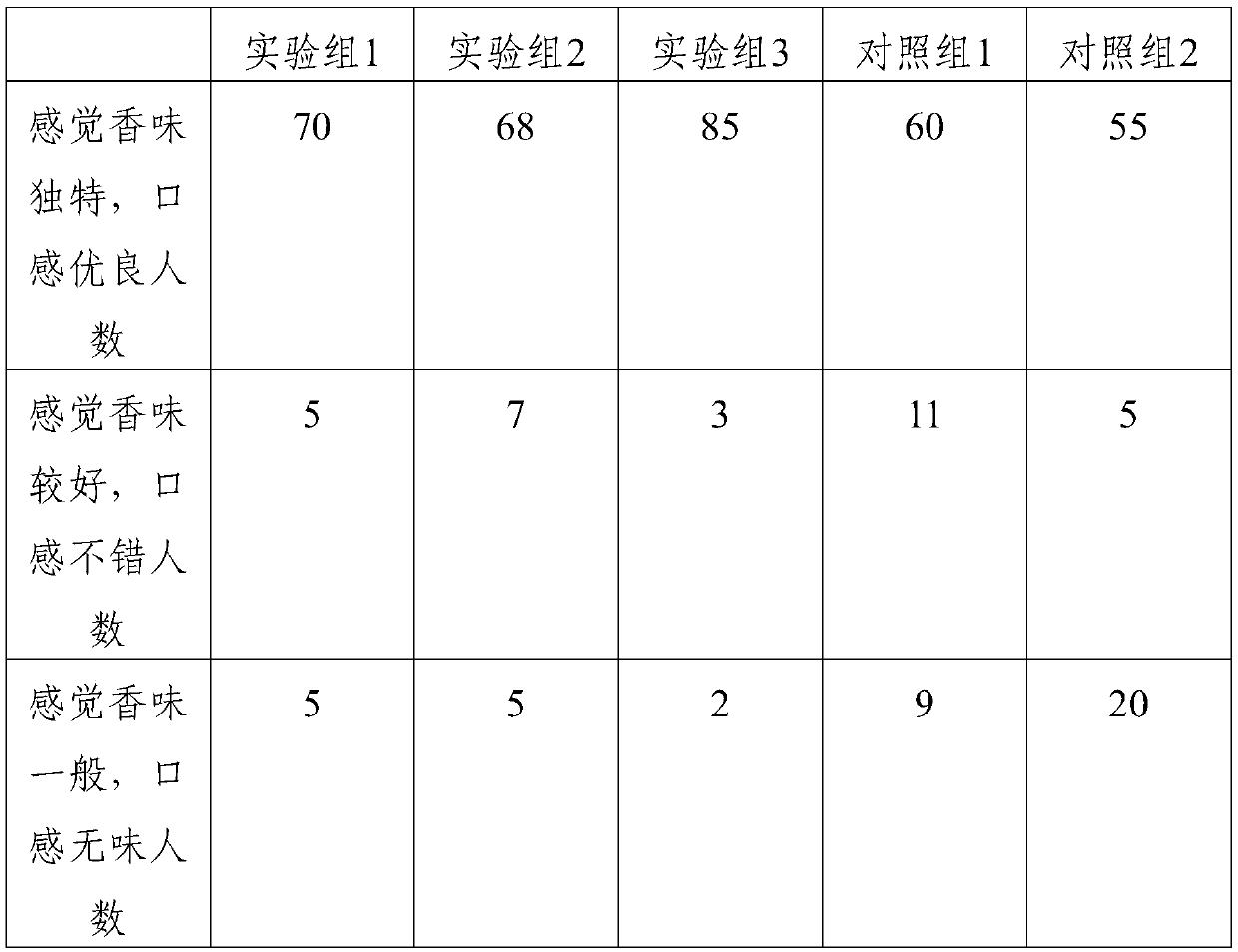

Examples

Embodiment 1

[0013] A microfiber black tea powder instant tea is prepared from the following raw materials by mass: 8 parts of black tea, 2 parts of microfiber fermented product, and 0.3 part of mineral salt;

[0014] The preparation method includes the following steps: (1) pulverizing the black tea into powder of 80 meshes, microwave treatment for 10 s, standing for 3 min, and then microwave treatment for 15 s; then pouring the powder into an ultra-fine pulverizer for ultra-fine pulverization to obtain black tea powder (2) Mix and beat hawthorn, mulberry and celery according to the mass ratio of 3:5:1, add fermenting microorganisms with 3% of the mass of the slurry to the obtained slurry and mix well, and ferment at 28 ° C for 20 hours; Under 34 ℃, ultrasonic treatment of 600W is carried out for 15 min, and then dried to a moisture content of 5% at 0.1 standard atmospheric pressure and 35 ℃, and the obtained dried product is ultrafinely pulverized to obtain a microfiber fermented product; ...

Embodiment 2

[0016] A microfiber black tea powder instant tea is prepared from the following raw materials by mass: 15 parts of black tea, 3 parts of microfiber fermented product, and 1 part of mineral salt;

[0017] The preparation method includes the following steps: (1) pulverizing the black tea into 100 mesh powder, microwave treatment for 12 s, standing for 5 min, and then microwave treatment for 20 s; then pouring the powder into an ultrafine pulverizer for ultrafine pulverization to obtain black tea powder (2) Mix and beat hawthorn, mulberry and celery according to the mass ratio of 3:5:1, add fermenting microorganisms with a mass of 4% of the slurry to the obtained slurry, mix well, and ferment at 32 ° C for 30 hours; Under 36 ℃, ultrasonic treatment of 700W is carried out for 20min, and dried to a moisture content of 8% at 0.3 standard atmospheric pressure and 38 ℃, and the obtained dried product is ultrafinely pulverized to obtain a microfiber fermented product; It is mixed from ...

Embodiment 3

[0019] A microfiber black tea powder instant tea is prepared from the following raw materials by mass: 9 parts of black tea, 2 parts of microfiber fermented product, and 0.8 part of mineral salt;

[0020] The preparation method includes the following steps: (1) pulverizing black tea into 90 mesh powder, microwave treatment for 11 s, standing for 4 min, and then microwave treatment for 18 s; then pouring the powder into an ultrafine pulverizer for ultrafine pulverization to obtain black tea powder (2) Mix and beat hawthorn, mulberry and celery according to the mass ratio of 3:5:1, add fermenting microorganisms with 3% of the mass of the slurry to the obtained slurry and mix evenly, and ferment at 32 ° C for 20h; Under 36 ℃, 600W of ultrasonic treatment was carried out for 20min, and dried to a moisture content of 5% at 0.1 standard atmospheric pressure and 38 ℃, and the obtained dried product was ultrafinely pulverized to obtain a microfiber fermented product; It is mixed from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com