Auxiliary gate electrode and solar cell

A technology of solar cells and auxiliary grids, applied in the field of solar cells, can solve the problems of difficult connection between main grids and auxiliary grids, large consumption of paste, affecting the process, etc., so as to save the unit consumption of auxiliary grid paste, reduce the volume, and reduce components. The effect of virtual welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

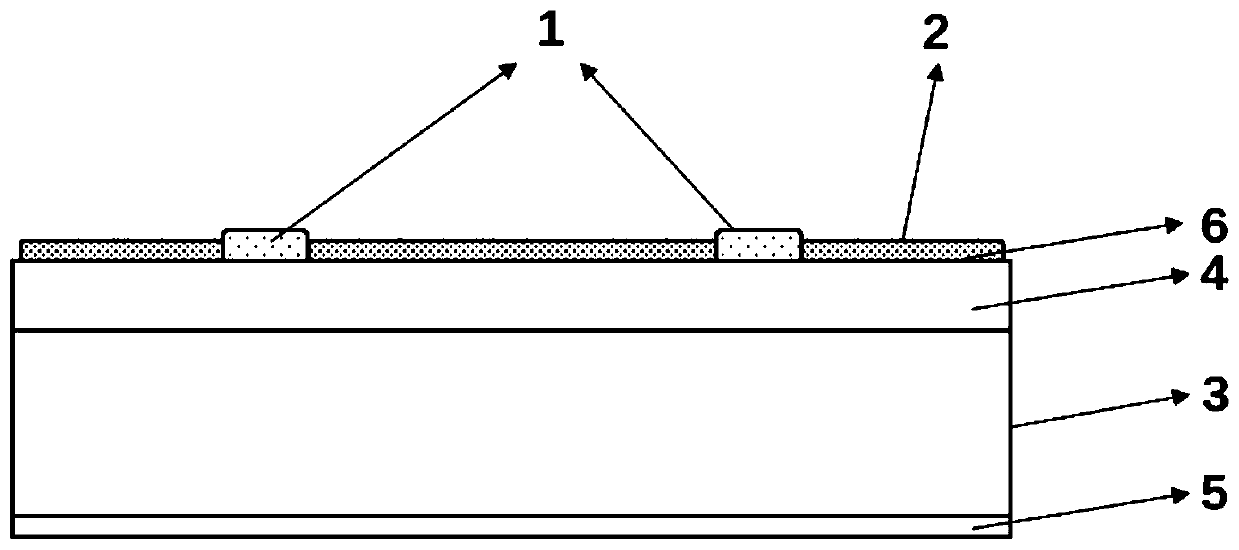

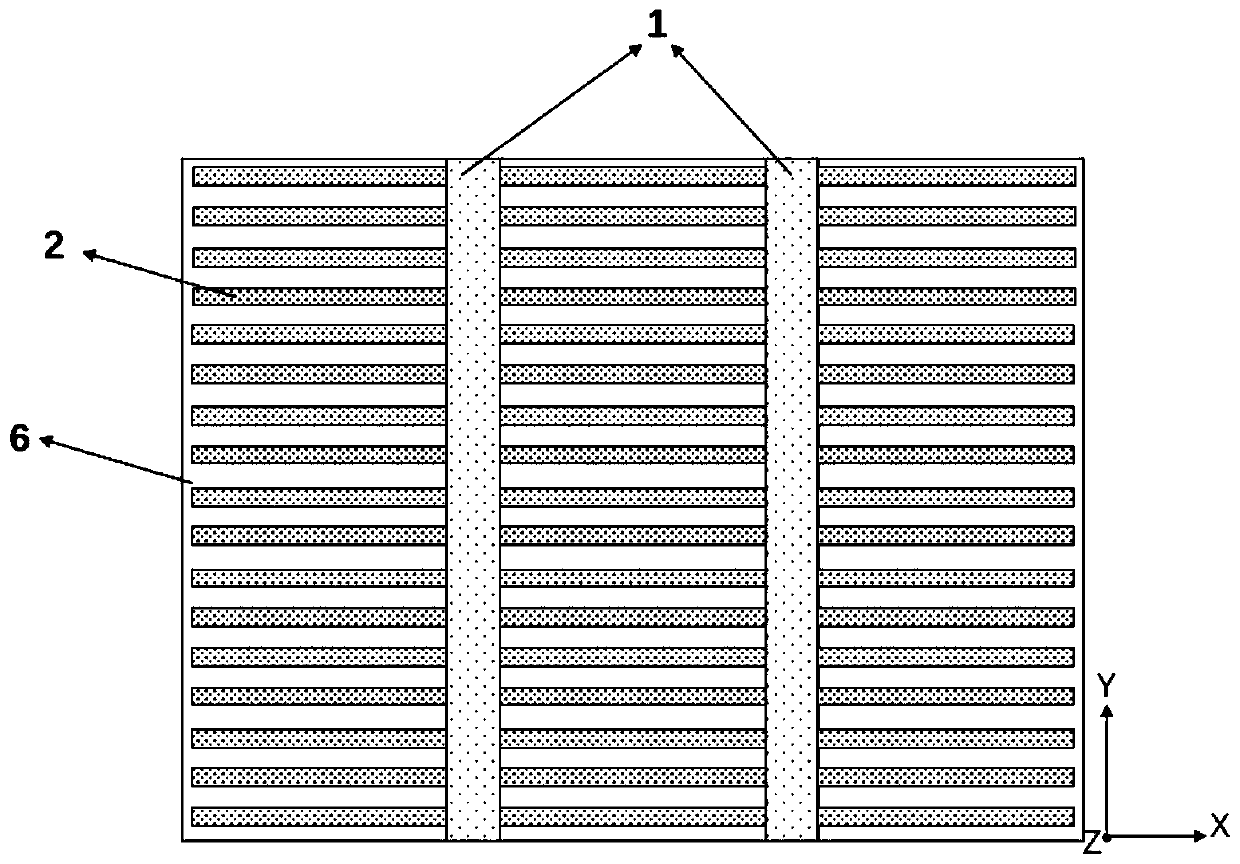

[0041] This patent is aimed at the grid-shaped main / sub-gate metal electrodes on the surface of the substrate, and the corresponding sub-gate electrodes adopt an improved and optimized innovative wedge shape such as Figure 8 As shown, the height of the side corresponding to the sub-gate 2 that overlaps the main grid 1 is the highest. In the corresponding Z direction, the maximum height of the general sub-gate can be 6um to 100um, and the height of the sub-gate 2 away from the main grid 1 must be smaller than that of the lap joint. The height of the auxiliary grid 2 at the main grid 1; the height value gradually decreases, that is, wedge-shaped, wherein the wedge-shaped auxiliary grid 2 gradually decreases from top to bottom, and the corresponding change can be linear or nonlinear, as long as it is consistent with the main grid 1 is higher than other parts, and the sub-gate 2 away from the main gate 1 is lower than the sub-gate 2 close to the main gate 1, so the silver paste is...

Embodiment 2

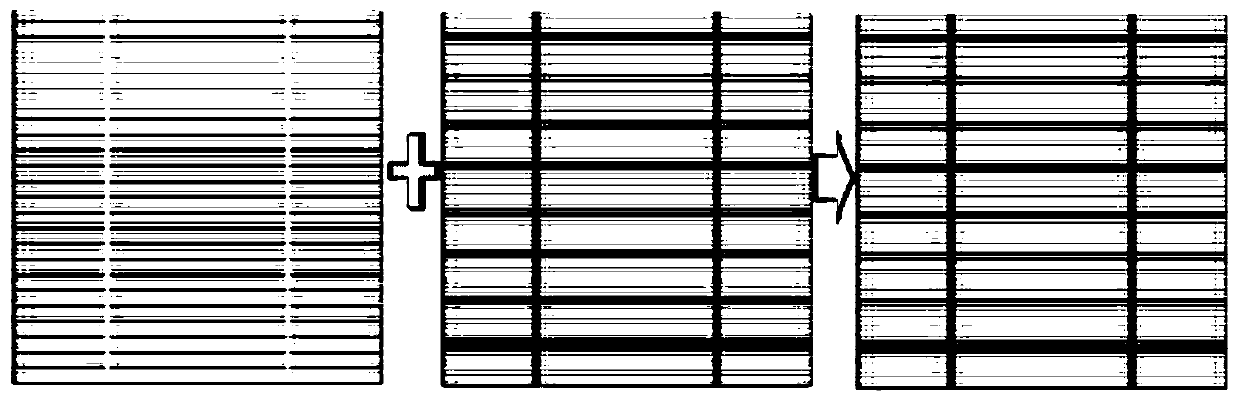

[0047] Embodiment 2 is basically the same as Embodiment 1, and in Embodiment 2, the lowered sub-gate 2 is a segmented lowered sub-gate 2 , such as Figure 10 As shown; the sub-gate 2 structure with segmental reduction can be a uniform width change, or a non-uniform change. Of course, the segmental reduction here is 90° iterative segmental reduction, that is, the sub-gate 2 in a ladder-shaped overlapping shape, Such as Figure 10 The step change shown can also be at other angles, such as a slant of 80°, as long as the section away from the main grid 1 is lower than the section close to the main grid 1, the silver paste will be reduced and the cost will be reduced . The corresponding effect can be guaranteed, and in terms of processing technology, it is more controllable and the cost of processing is lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap