A kind of back contact crystalline silicon cell and its manufacturing method

A technology of crystalline silicon battery and manufacturing method, which is applied in the field of solar cells, can solve the problems of increasing the difficulty and complexity of the manufacturing process, affecting the mechanical strength of the device, and increasing the production cost, so as to avoid shading loss and improve electrical performance and reliability , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific production method steps include:

[0038] Step 1: If figure 1 As shown, the surface of the silicon wafer is pretreated to remove surface impurities and surface oxide layers, and after completion, it is cleaned with deionized water.

[0039] Step 2: Anisotropic texture is chemically etched on the surface of the N-type silicon substrate 1 to produce a pyramid-shaped light-trapping structure.

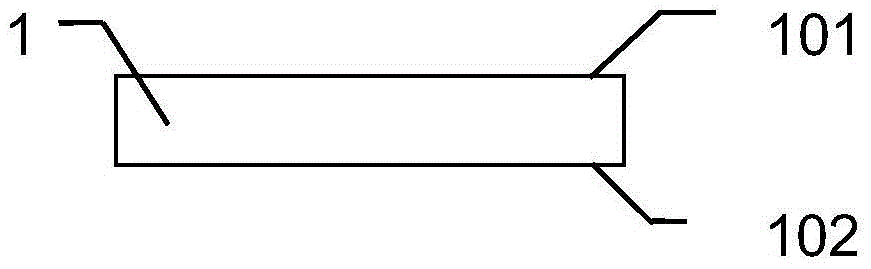

[0040] Step 3: If figure 2 1. Perform a polishing process on the non-light-receiving surface 101 of the silicon substrate 1 forming the textured structure, and perform standard cleaning on the silicon wafer after polishing. The cleaning process is the same as step 1.

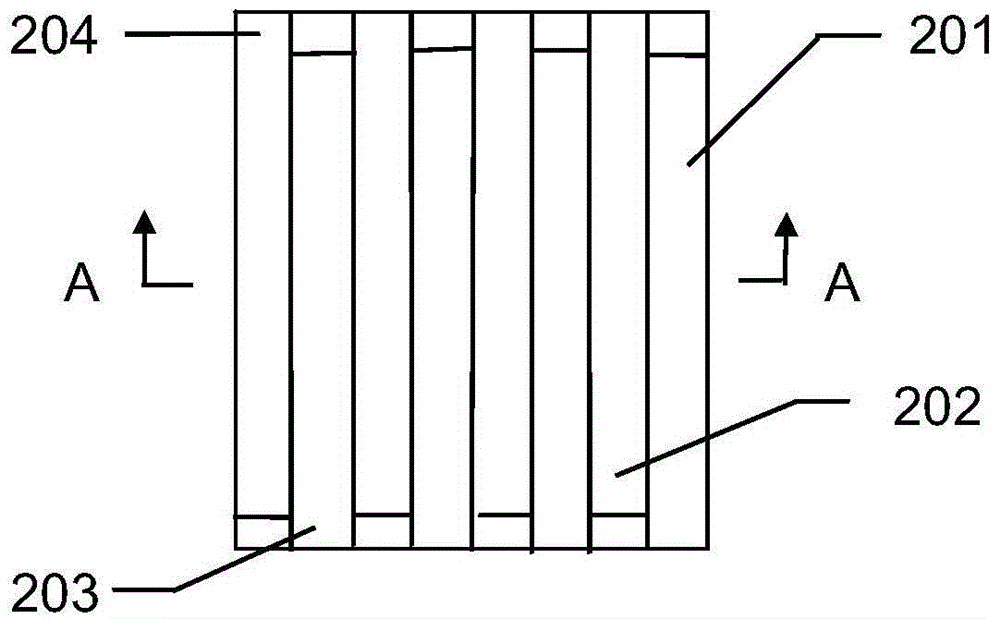

[0041] Step 4: If Figures 3 to 4As shown, the method of ion implantation is used to do boron (B) doping on the non-light-receiving surface 101 of the silicon substrate, the energy of ion implantation is 1-200keV, and the dose is 5x10 14 ~5x10 17 / cm 2 , the time is 1-60s, and the substrate tempera...

Embodiment 2

[0053] Optimized with respect to Example 1.

[0054] Step 9: Using sputtering, thermal evaporation or electroplating metallization process, fabricate a P-type area converging conductive belt 301 above the P-type area 201 of the solar cell, and fabricate an N-type area converging conductive belt 302 above the N-type area 202 of the non-light-receiving surface of the battery .

Embodiment 3

[0056] Optimized with respect to Example 1.

[0057] Step 9: Using sputtering, thermal evaporation or electroplating metallization process, fabricate a P-type area converging conductive belt 301 above the P-type area 201 of the solar cell, and fabricate an N-type area converging conductive belt 302 above the N-type area 202 of the non-light-receiving surface of the battery . The P-type region converging conductive strip 301 and the N-type region converging conductive strip 302 are Al, Ag, Au, Ni, Cu, Cu / Ni, Al / Ni or Ti / Pd / Ag electrodes, and their thickness is 0.05um-600um , and the P-type area busbars 301 and the N-type area busbars 302 are alternately arranged, that is, an arrangement structure of P-N-P-N area busbars is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap