Method for preparing indium bumps of reading circuit of infrared detector

A technology for infrared detectors and readout circuits, which is applied in the direction of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of inability to prepare high-uniformity indium bumps, and achieve low preparation difficulty and high uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

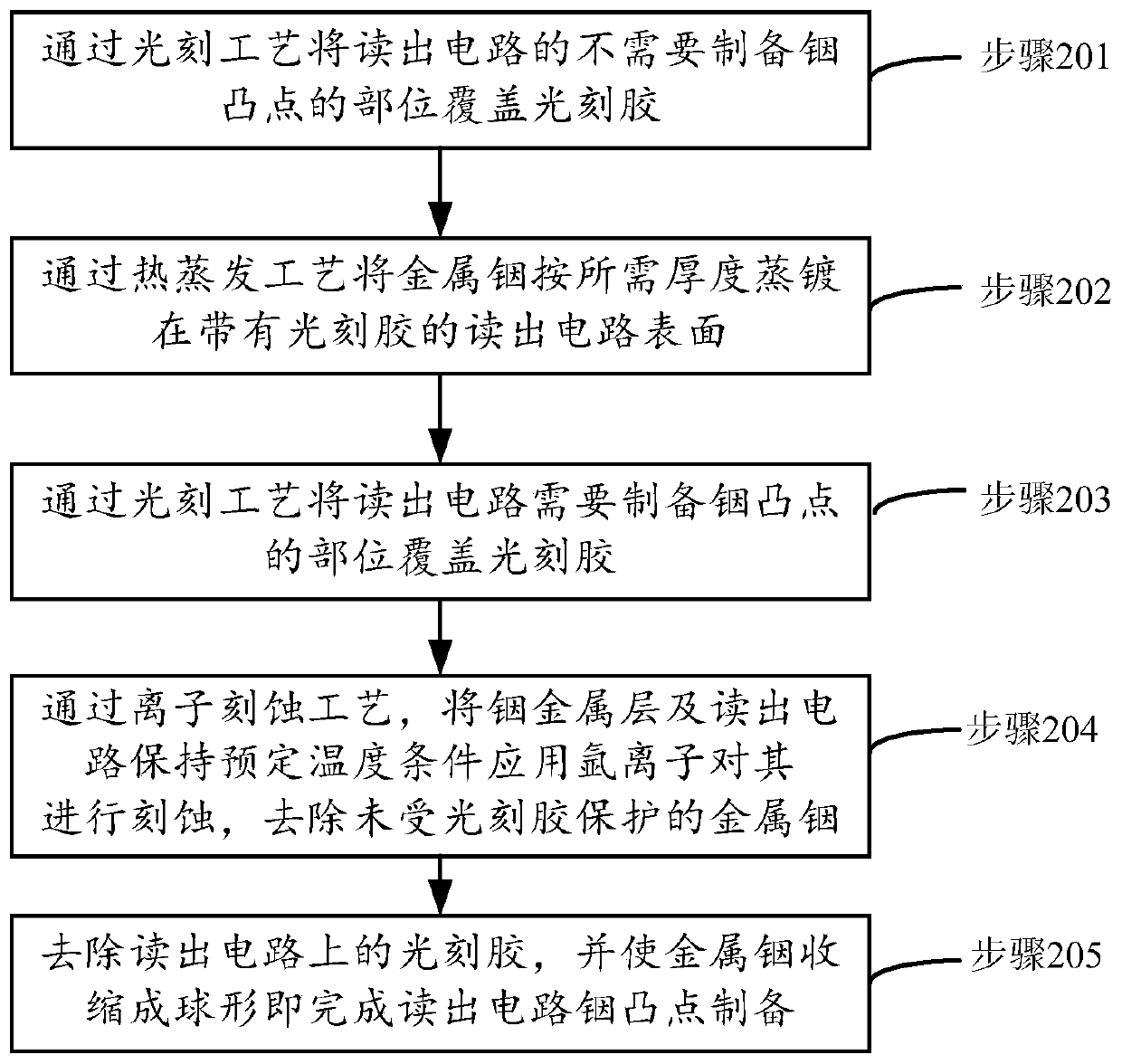

[0025] According to an embodiment of the present invention, a method for preparing an indium bump for an infrared detector readout circuit is provided, figure 2 It is a flow chart of the method for preparing an indium bump for an infrared detector readout circuit according to an embodiment of the present invention, such as figure 2 As shown, the method for preparing an indium bump for an infrared detector readout circuit according to an embodiment of the present invention specifically includes:

[0026] Step 201 , covering the parts of the readout circuit that do not require indium bumps with photoresist through a photolithography process; wherein, the thickness of the photoresist covering the parts that do not need indium bumps is 1 μm.

[0027] Step 202, evaporating metal indium on the surface of the readout circuit with photoresist according to the required thickness by thermal evaporation process;

[0028] Step 203, covering the parts of the readout circuit where indium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com