Homogenized incoherent light source device

An incoherent light source and light source technology, applied in optics, optical components, instruments, etc., can solve the problems of strong dependence and low energy utilization efficiency of the light source, and achieve low dependence, small pump uniformity, and obvious output light intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

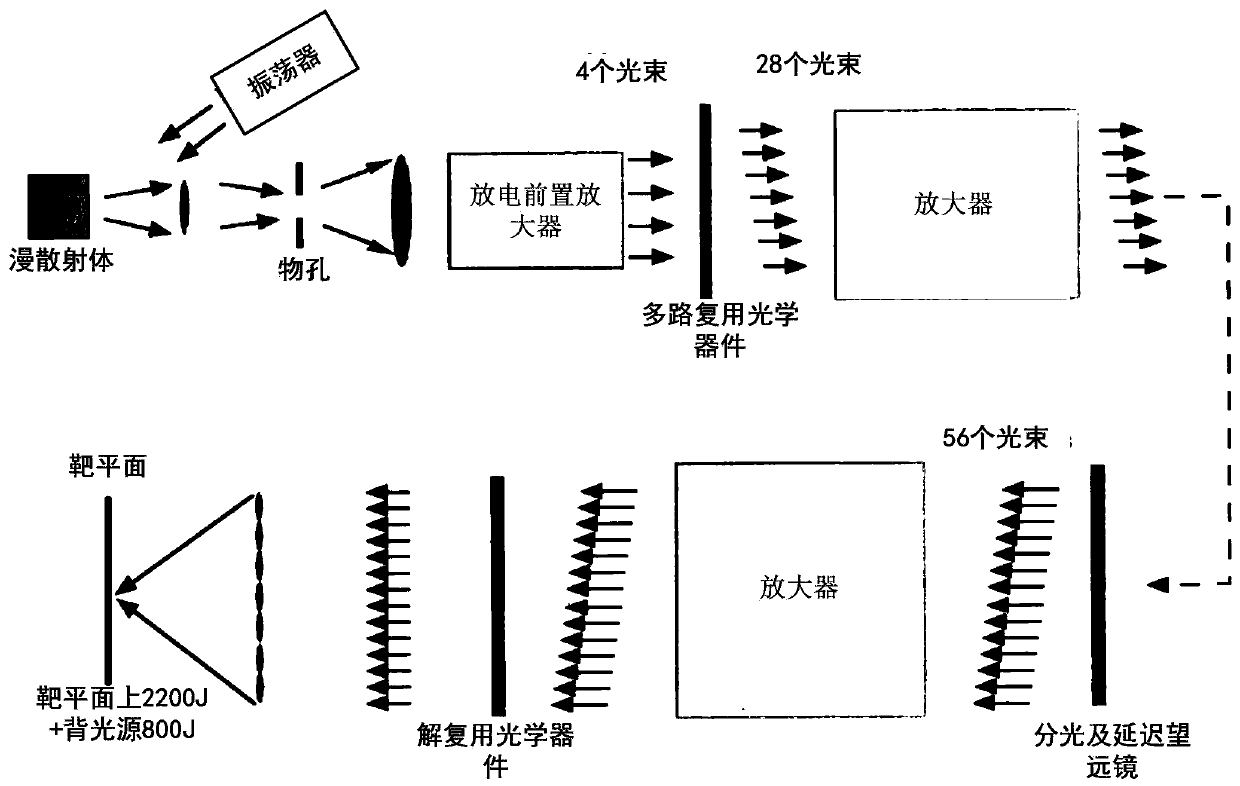

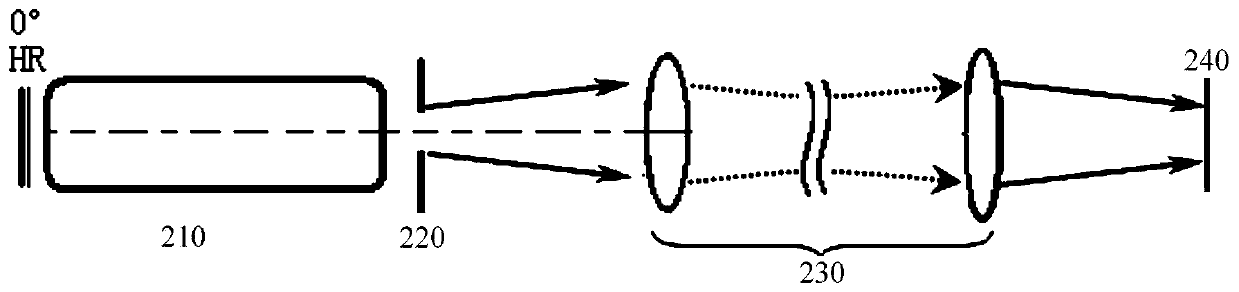

[0036] Figure 4 It is a schematic diagram of the optical path layout of the homogenized incoherent light source device of Embodiment 1 of the present disclosure. like Figure 4 As shown, the homogenized incoherent light source device of Embodiment 1 includes an amplified spontaneous emission (ASE) light source 410 , a beam coupling unit 420 , and a homogenized light guide 430 . The ASE light source 410, the beam coupling unit 420, and the uniform light guide 430 are sequentially placed along the beam propagation direction, and the position and orientation of the placement make the light emitted by the amplified spontaneous radiation source 410 coupled to the input end surface of the uniform light guide 430, and the uniform light guide The ratio of the length to the aperture of 430 is greater than or equal to a preset ratio, so that the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com