A kind of polymer composite material regeneration treatment equipment and treatment method

A composite material and processing equipment technology, which is applied in the field of polymer composite material regeneration processing equipment, can solve a large amount of waste gas, waste liquid and waste impurities, endanger the ecological environment and human health, and achieve energy saving, high flexibility, and equipment Process adjustable and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will introduce the embodiments and the accompanying drawings of the prior art operation scheme. The following embodiments will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention. These belong to the protection scope of the present invention.

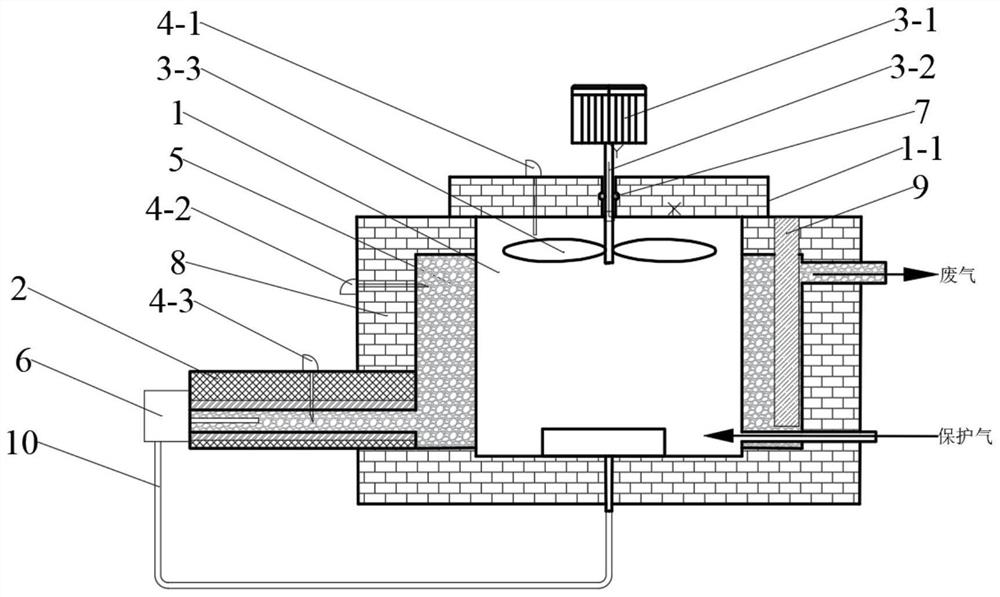

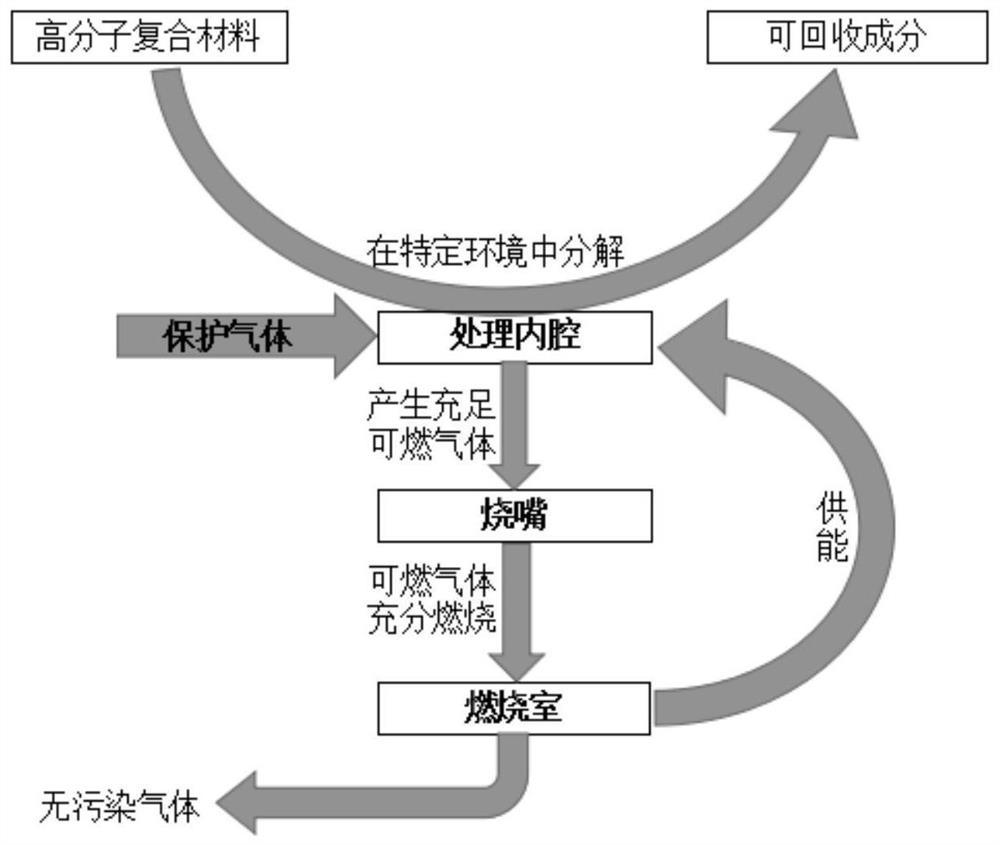

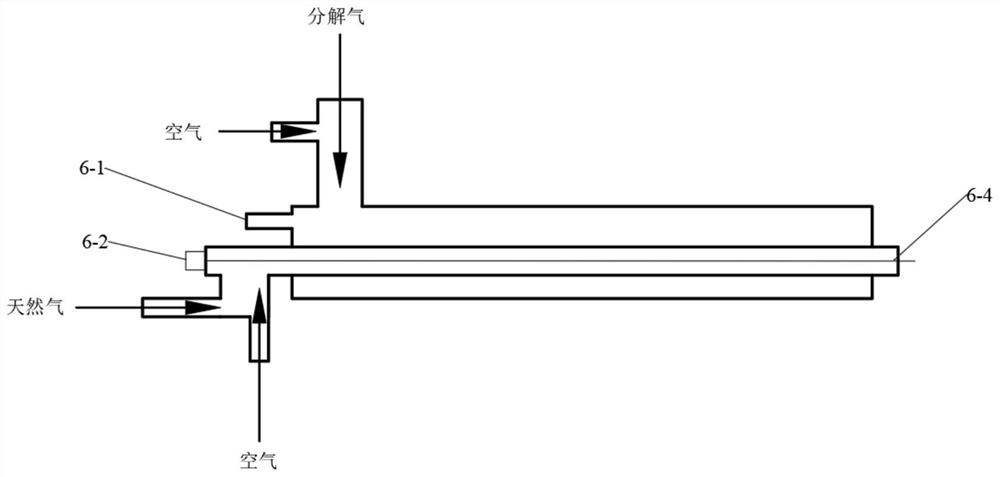

[0032] Such as figure 1 As shown, a polymer composite regeneration treatment equipment includes a treatment furnace 1, an auxiliary purification device 2, a gas flow control device 3, a temperature detection device 4, a combustion chamber 5 and a burner 6, and the combustion chamber 5 converts the treatment furnace 1 is packaged as a whole, and the gas flow control device 3 is embedded in the furnace cover of the treatment furnace 1. The inner cavity of the treatment furnace 1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com