High-strength steel member

A high-strength steel and component technology, applied in the field of high-strength steel components, can solve the problems of ductility or toughness reduction, quenching cracks, etc., and achieve the effect of excellent delayed fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

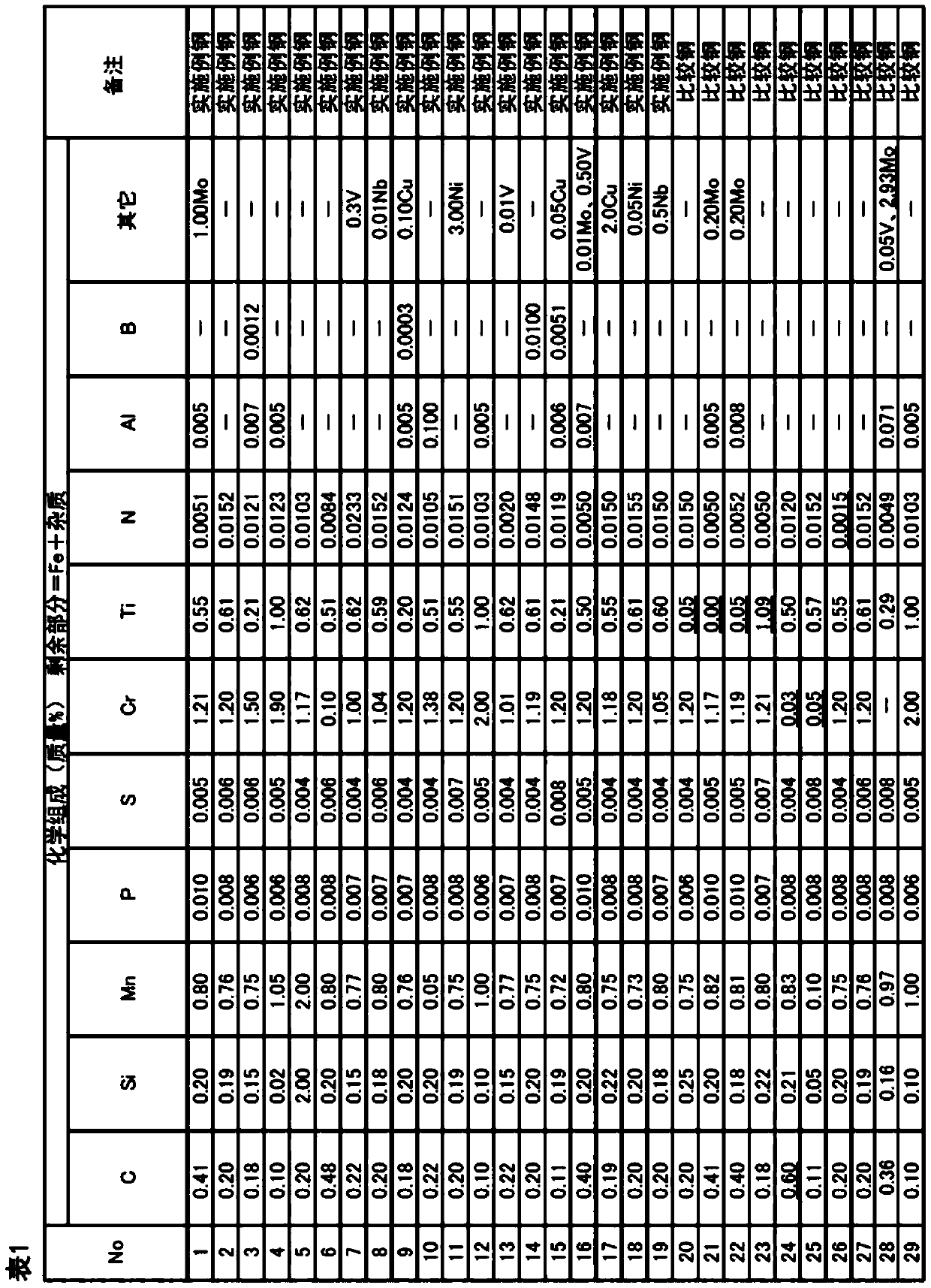

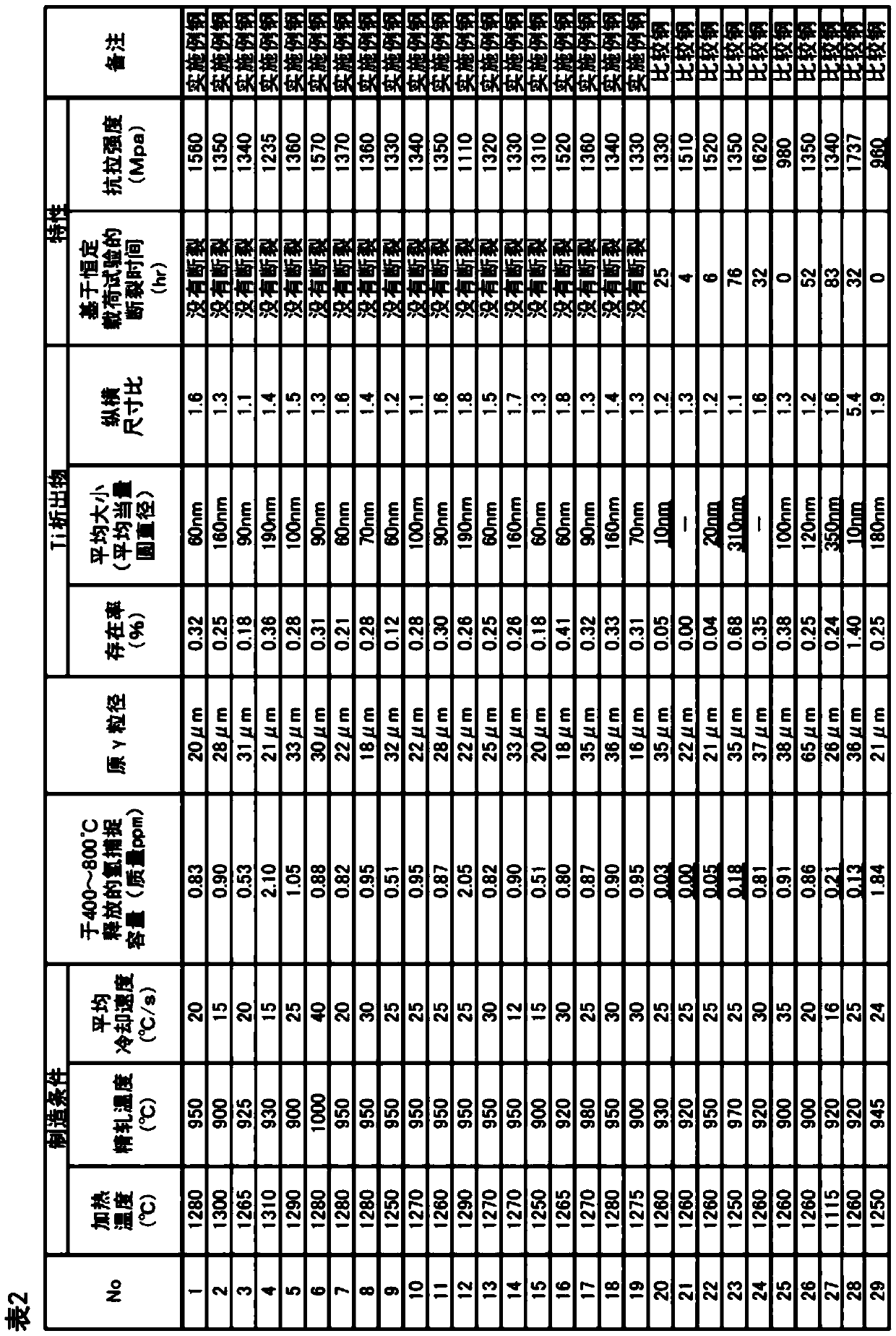

[0141] Examples are given below to further describe the present invention in detail. However, these respective Examples do not limit the present invention.

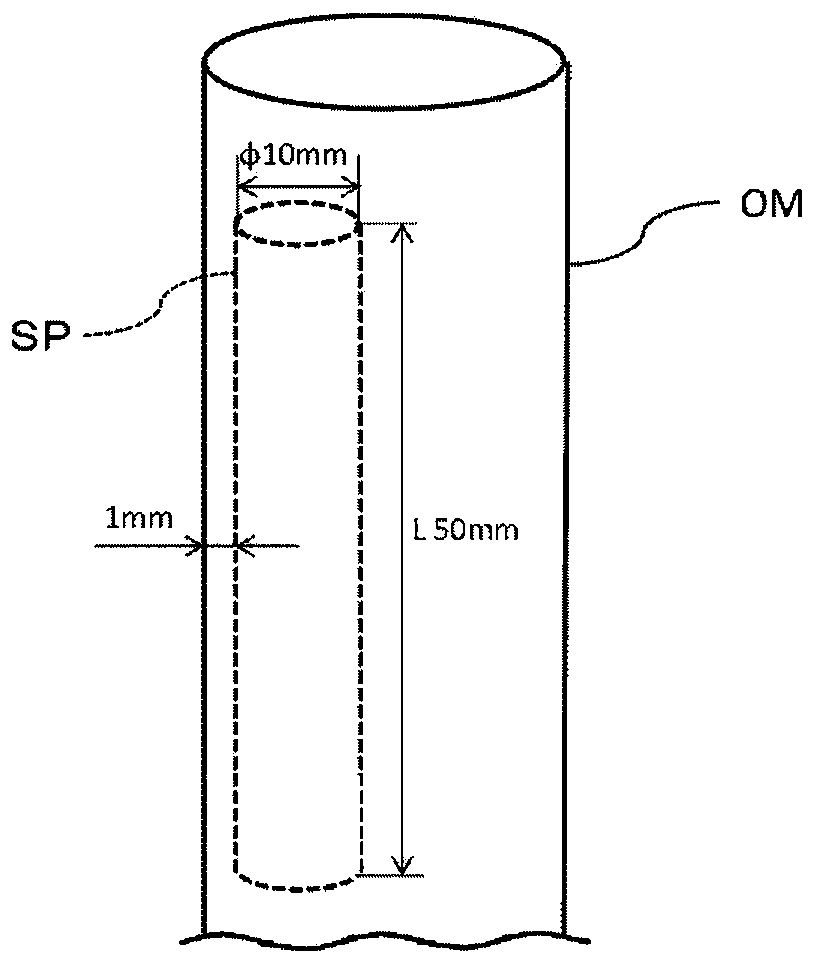

[0142] The test material having the chemical composition shown in Table 1 was heated to the temperature shown in Table 2, then hot rolled at the finish rolling temperature shown in Table 2, and cooled to 700°C at the average cooling rate shown in Table 2, Thereby, it was rolled to φ20mm, and an annular notched test piece (notch depth 2mm, notch bottom radius 0.25mm, notch angle 60 degrees) made of round bar steel with a size of φ10mm×L50mm was produced.

[0143] Heat the test piece under the conditions of simulating carburizing heating atmosphere or RX gas heating (1 atmosphere pressure, 50% hydrogen and Ar mixed atmosphere, heating temperature 1000°C, heating time 30 minutes), at a rate of 40°C / s or less Cooling rate Water cooling to 20°C for quenching, followed by tempering at 150°C for 20 minutes.

[0144] However, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com