Bamboo-hemp winding composite pressure pipe and preparation method thereof

A composite pressure pipe, bamboo hemp technology, applied in the direction of pipes, rigid pipes, manufacturing tools, etc., can solve the problems of difficult to achieve reasonable control of pipe performance, restricting the application and development of bamboo composite pipes, unable to meet the requirements of pipe ring stiffness, etc. To achieve the effect of convenient control, excellent resistance to internal and external pressure, and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

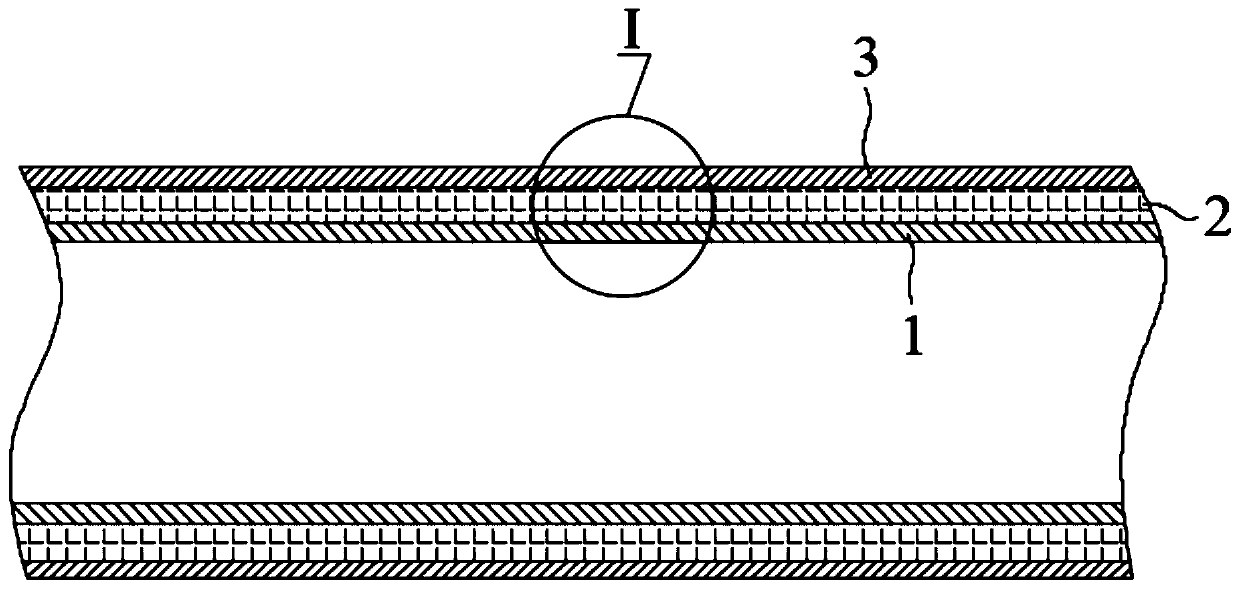

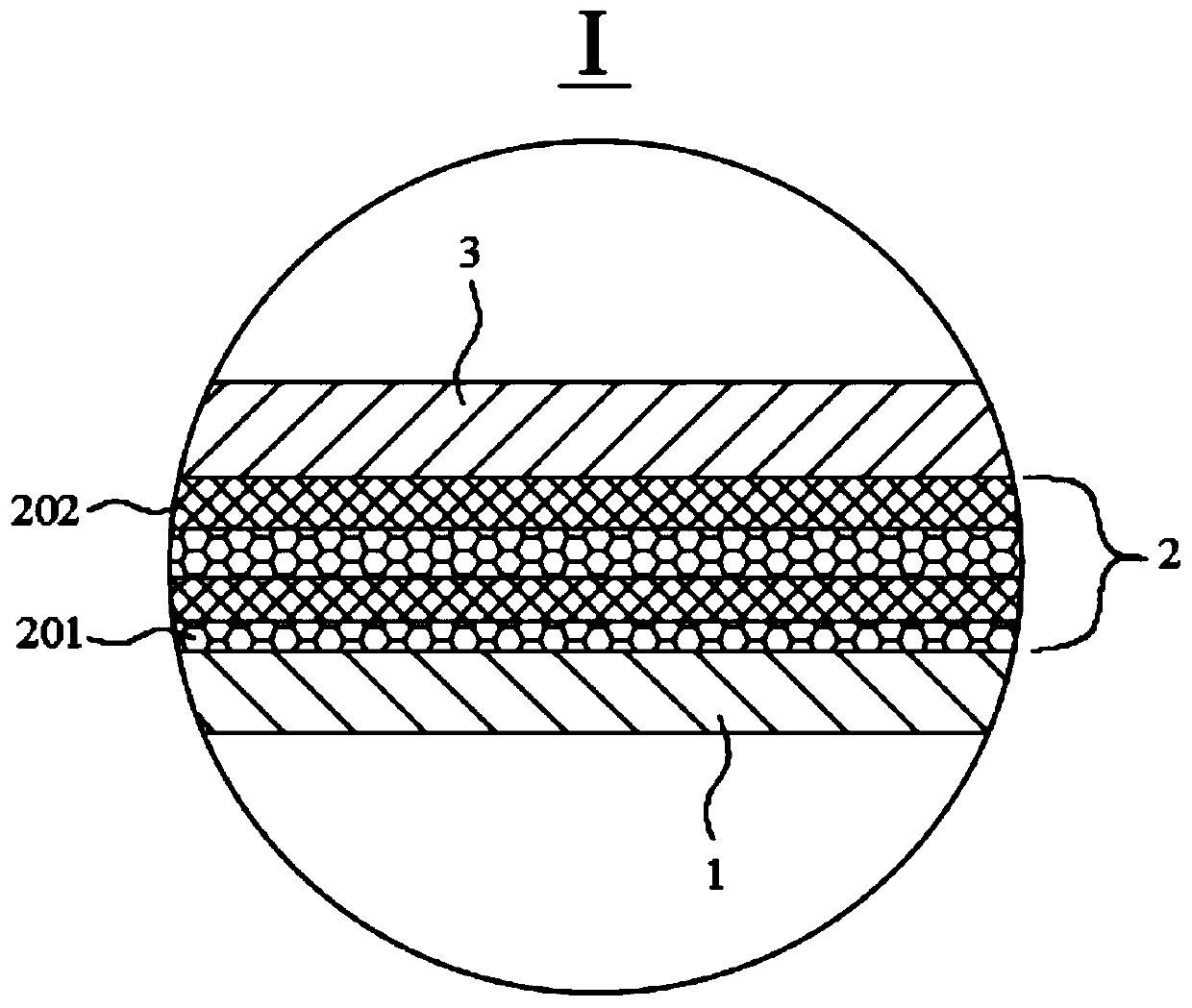

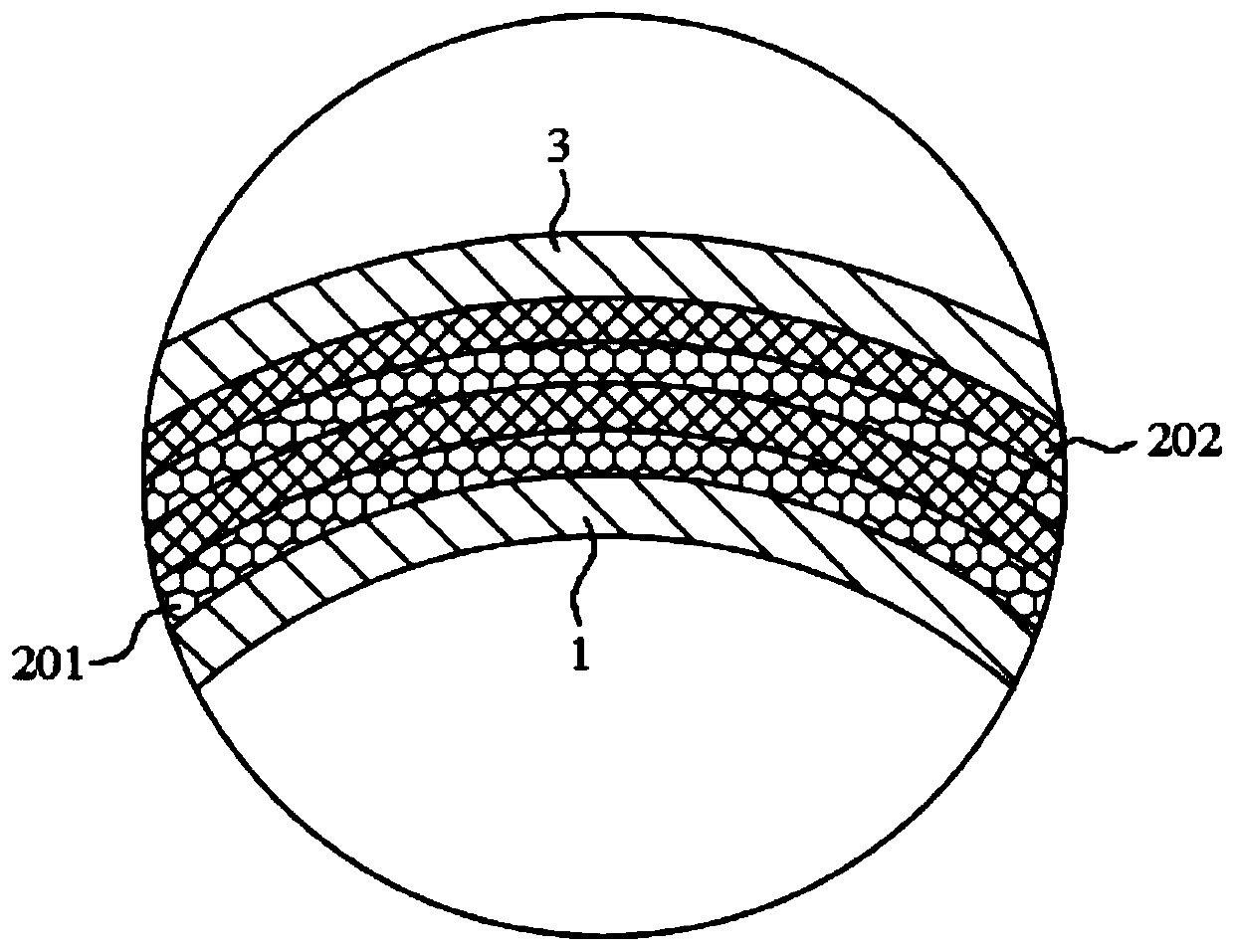

[0044] In preferred embodiment 1 of the present invention, the composite pressure pipe wrapped with bamboo and hemp is as figure 1 shown in . Wherein, the composite pressure pipe is formed into a tubular shape, and it includes an inner lining layer 1, a structural layer 2 and an outer protective layer 3 sequentially from the inside to the outside.

[0045] Specifically, the inner lining layer 1 and the outer protective layer 3 in the preferred embodiment 1 are preferably made of the same or similar materials as the inner lining layer and the outer protective layer in the existing bamboo winding composite pipe or the existing hemp winding composite pipe It is formed by winding and bonding, and will not be described in detail here.

[0046] Further, as figure 2 , 3 As shown in , the structural layer 2 in the preferred embodiment 1 is formed by bonding two layers of hemp winding units 201 and two layers of bamboo winding units 202 arranged at intervals from the inside and out...

Embodiment 2

[0068] In this embodiment, the molding process of the bamboo and hemp winding composite pressure pipe is substantially the same as that in Embodiment 1, the difference is that when forming the structural layer 2, there are two hemp winding units 201 formed by winding and bonding, and the bamboo The winding unit 202 is one set between the two hemp winding units 201, that is, the partial structure enlarged view of the bamboo and hemp winding composite pressure pipe obtained after molding is shown in Figure 4 shown in .

Embodiment 3

[0070] In this embodiment, the molding process of the bamboo and hemp wound composite pressure pipe is substantially the same as that in Embodiment 1, the difference is that when forming the structural layer 2, there are two bamboo winding units 202 formed by winding and bonding, and the hemp The winding unit 201 is the one arranged between the two bamboo winding units 202, that is, the enlarged view of the local structure of the bamboo and hemp winding composite pressure pipe obtained after molding is shown in Figure 5 shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com