Pichia pastoris strain, keratinase produced by fermentation of pichia pastoris strain and application of keratinase

A technology of Pichia pastoris and keratinase, which is applied in the application field of keratinase and keratinase, can solve the problems of animal absorption and utilization rate, low degradation rate and gene mutation that affect the nutritional value of feed, so as to facilitate animal digestion and absorption and preparation Simple method and mild degradation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Breeding method of Pichia pastoris.

[0025] A: The target gene Fpk encoding keratinase (as shown in SEQ ID NO: 1) was cloned from Aspergillus fumigatus; the expressed protein is shown in SEQ ID NO: 2.

[0026] B: Design primers according to the target gene, and perform PCR (including 10 times buffer and Taq enzyme, dNTP and other In-Fusion kits) to obtain the target gene sequence Fpk (as shown in SEQ ID NO: 1);

[0027] Primer F: 5'-ctcctgccaagctgaagc-3',

[0028] Primer R: 5'-gatcatggaacggattc-3',

[0029] Amplification program: 95°C for 2min; 95°C for 30s, 56°C for 30s, 72°C for 1min, 45 cycles; 72°C for 5min; store at 4°C.

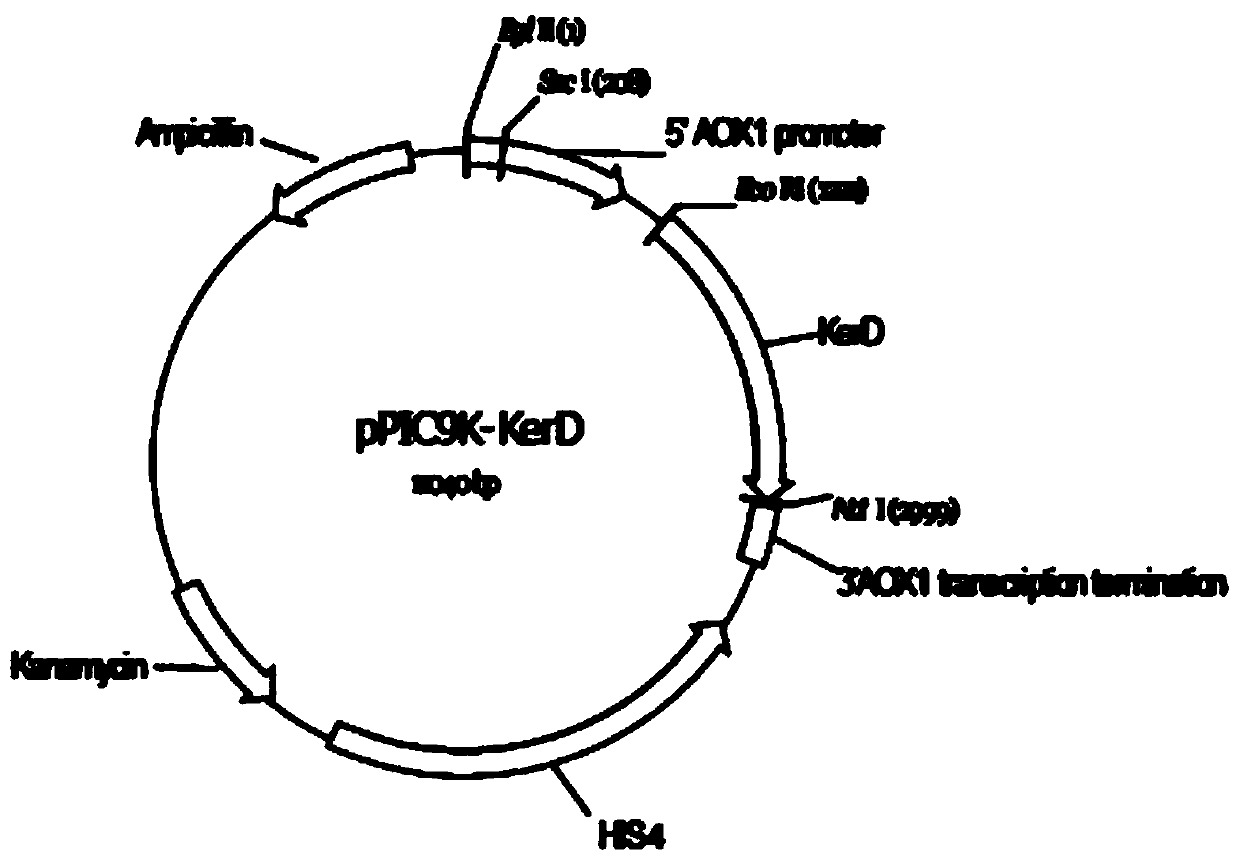

[0030] C: Insert the obtained target genes into the expression vector pPIC9k respectively, and then transfer them into E. coli DH5α competent cells, use the LB plate containing kanamycin to screen the positive clones, verify the colony PCR and enzyme digestion, the fragment size is correct and then Sequencing identification was carried out to...

Embodiment 2

[0034] Induced expression and detection of Pichia pastoris AN-PK-9K-GS115

[0035] (1) Transfer the obtained Pichia pastoris AN-PK-9K-GS115 to the YPD plate, then select a single colony and transfer it to the fermentation medium, and culture it for 20-24 hours at 30°C and 180rpm as a seed solution.

[0036] Fermentation medium: 85% phosphoric acid 26.7mL / L, CaSO 4 0.93g / L,K 2 SO 4 18.2g / L, MgSO 4 ·7H 2 O14.9g / L, KOH 4.13g / L, glycerin 40g / L.

[0037] (2) The mass fraction of the seed liquid is 5% inserted in a 50L fermenter containing 35L BSM inorganic salt medium (Shanghai Yubo Biotechnology Co., Ltd.), the pH value is controlled at 5, the temperature is 30 ° C, and the stirring speed is adjusted. Be 600rpm, dissolved oxygen DO is controlled at 10%, along with the carrying out of fermentation, dissolved oxygen rises to 30% and when continuing 30-60min, regulating stirring speed is 800rpm, and replenishes methyl alcohol once (replenishment is 1.5% of total volume ), an...

Embodiment 3

[0041] Feather meal keratinase enzymolysis feather meal

[0042] The application method of feather powder keratinase of the present invention in the enzymatic hydrolysis of chicken feather powder is to dry the feather powder keratinase crude enzyme liquid fermented for 60h in Example 4, and then use the dried feather powder keratinase crude enzyme enzymolysis Chicken feather powder, specifically:

[0043] (1) Mix chicken feather powder with water, prepare chicken feather powder and water according to the mass ratio of 1:5, 1:9, and 1:10 respectively, adjust the pH value to 6, and add dry feather powder keratinase crude oil at 25°C Enzyme, the amount added is 4500U per gram of chicken feather powder, enzymatic hydrolysis for 35h, and the decomposition rate of chicken feather powder is determined.

[0044] According to the above enzymatic hydrolysis, it was found that chicken feather powder and water were prepared at a mass ratio of 1:5, the feather decomposition rate was 60.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com