Method for double-frequency composite ultrasonic degradation of phenol in rural sewage

A composite ultrasonic and rural sewage technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low ultrasonic degradation rate and achieve the effect of enhanced degradation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Influencing factors of embodiment 1 probe type ultrasonic degradation of phenol

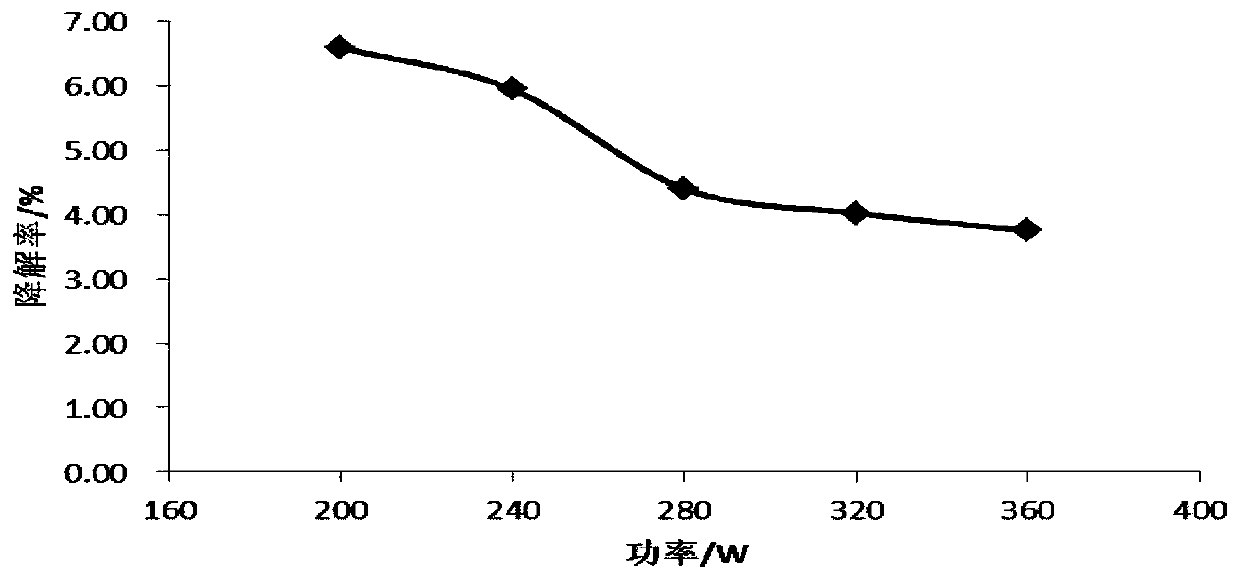

[0043] 1.1 Influence of ultrasonic power

[0044] Adjust the ultrasonic power to 200W, 240W, 280W, 320W, and 360W, sequentially take 80mL of 4mg / L phenol solution into a 150mL beaker, and use probe-type ultrasonic treatment for 20min. Experimental results such as figure 1 shown.

[0045] Depend on figure 1It can be seen that with the increase of ultrasonic power, the degradation rate of phenol decreases. When the power is 200W and 360W, the corresponding degradation rates are 6.59% and 3.75%. The possible reason is: when the ultrasonic power reaches a certain level, the cavitation bubble grows too large, causing the cavitation bubble to be compressed to collapse before it is too late. In addition, when the sound energy is too large, when the negative phase of the sound wave is too large to inhibit the formation of cavitation bubbles, the cavitation bubbles will form a shielding effect...

Embodiment 2

[0054] Influencing factors of embodiment 2 tank type ultrasonic degradation of phenol

[0055] 2.1 Influence of ultrasonic power

[0056] Use a graduated cylinder to measure 80 mL of phenol solution with a concentration of 4 mg / L into a glass test tube, and sonicate at 200 W, 240 W, 280 W, 320 W, and 360 W ultrasonic power for 20 minutes. The result is as Figure 4 shown.

[0057] Depend on Figure 4 It can be seen that the degradation rate is 6.20% when the power is 200W, 5.10% when the power is 240W, and 2.40% when the power is 360W. In general, the degradation rate of phenol is not high by using ultrasonic bath alone. This may be because at a certain ultrasonic power, the cavitation bubble grows too large, causing the cavitation bubble to be compressed to collapse before it is too late.

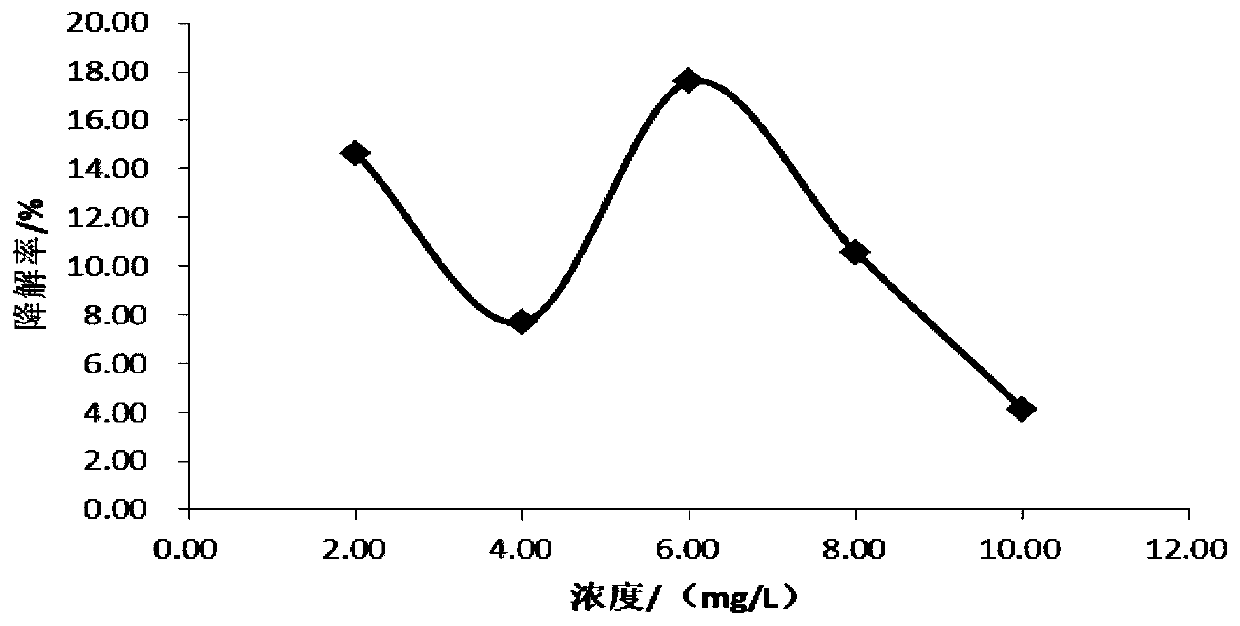

[0058] 2.2 Effect of initial concentration

[0059] Accurately pipette the phenol standard intermediate solution in turn to prepare solutions with initial concentrations of 2.00, 4.0...

Embodiment 3

[0066] Influencing factors of embodiment 3 dual-frequency composite ultrasonic degradation of phenol

[0067] Since the power of the dual-frequency composite ultrasound can be combined in many ways, the embodiment of the present invention adopts a fixed slot-type ultrasound power of 160W, and only changes the power of the probe-type ultrasound in the process.

[0068] 3.1 Influence of ultrasonic power

[0069] Use a graduated cylinder to measure 80 mL of the sample solution into a glass test tube, fix the power of the tank-type ultrasound to 160W, adjust the power of the probe-type ultrasound to 40W, 80W, 120W, 160W, and 200W, and ultrasound for 20 minutes. The result is as Figure 7 shown.

[0070] Depend on Figure 7 It can be seen that the degradation effect of dual-frequency composite ultrasound decreases with the increase of power. The degradation rate was 4.90% when the ultrasonic power was 200W, and decreased to 0.97% when the ultrasonic power was 360W.

[0071] 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com