Biomass oil-gas co-production device and method based on chemical chain

A biomass and chemical chain technology, which is applied in the fields of biofuel, gasification process, petroleum industry, etc., can solve the problems of gasification gas production cost increase, waste, water resource waste energy, etc., to achieve self-heat balance and ensure full Effects of pyrolysis, enhanced contact and heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

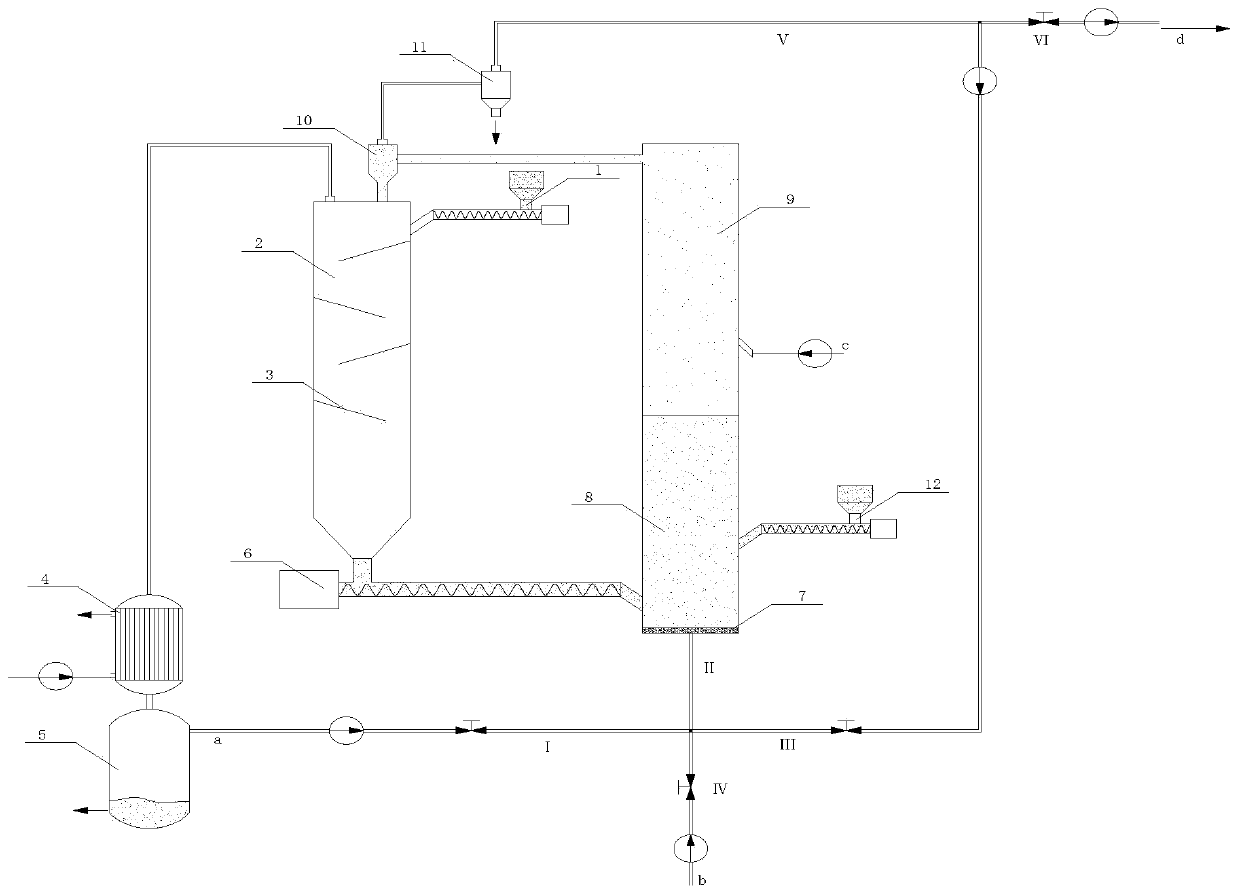

[0065] A certain amount of oxygen carrier particles (Ca 2 Fe 2 o 5 ) into the fuel reaction chamber 8 as bed material, and the bed material is preheated to 800°C. Turn on the steam generator, wait for the water vapor to fill the entire oxidation reaction chamber 9 and keep it stable, open the fluidizing gas valve to make the oxygen carrier particles circulate stably between the pyrolysis reactor 2 and the gasification reactor, by adjusting the flow rate of the fluidizing gas Control the temperature of pyrolysis reactor 2 to maintain at 450°C all the time. The biomass raw material (rice straw) enters the pyrolysis reactor 2 from the first screw feeder 1, and under the action of the baffle plate 3, the biomass is fully mixed with the oxygen carrier and undergoes pyrolysis reaction. The reacted solid product is sent to the fuel reaction chamber 8 through the screw feeder 6, and the pyrolysis gas pipeline I and the fluidization gas CO are not condensed at the same time. 2 The ...

Embodiment 2

[0067] A certain amount of oxygen carrier particles (Ca 2 Fe 2 o 5 / MgO) is charged into the fuel reaction chamber 8 as bed material, and the bed material is preheated to 850°C. Turn on the steam generator, wait for the water vapor to fill the entire oxidation reaction chamber 9 and keep it stable, open the fluidizing gas valve to make the oxygen carrier particles circulate stably between the pyrolysis reactor 2 and the gasification reactor, by adjusting the flow rate of the fluidizing gas Control the temperature of pyrolysis reactor 2 to maintain at 480°C all the time. The biomass raw material (cotton stalk) enters the pyrolysis reactor 2 from the first screw feeder 1 , and under the action of the baffle plate 3 , the biomass is fully mixed with the oxygen carrier and undergoes pyrolysis reaction. The reacted solid product is sent to the fuel reaction chamber 8 through the screw feeder 6, and the pyrolysis gas pipeline I and the fluidization gas CO are not condensed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com