Staurosporine extraction method

A staurosporine and extraction method technology, applied in the field of separation and purification of chemicals, can solve the problems of poor quality staurosporine, content of only 89%, high production cost, etc., achieve short production cycle, easy to scale up, and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

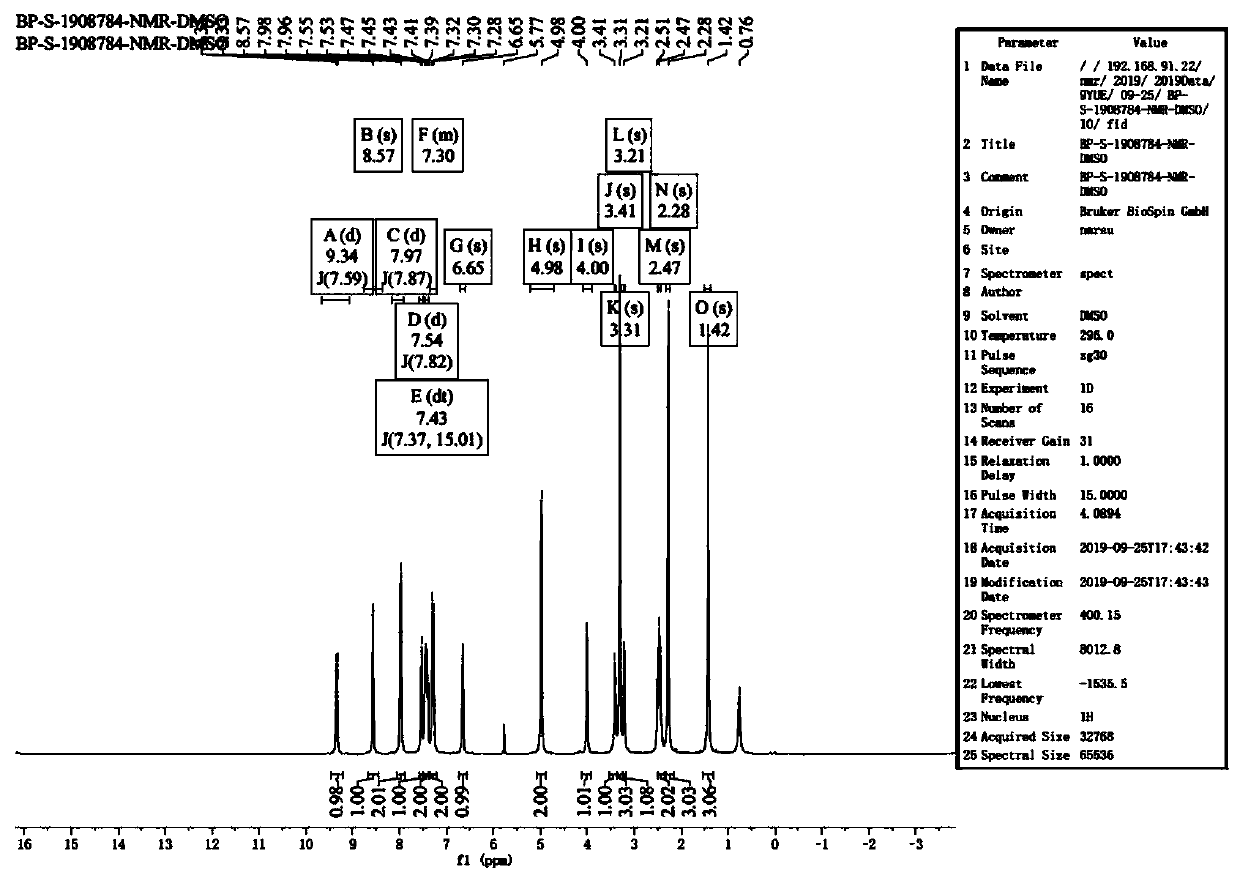

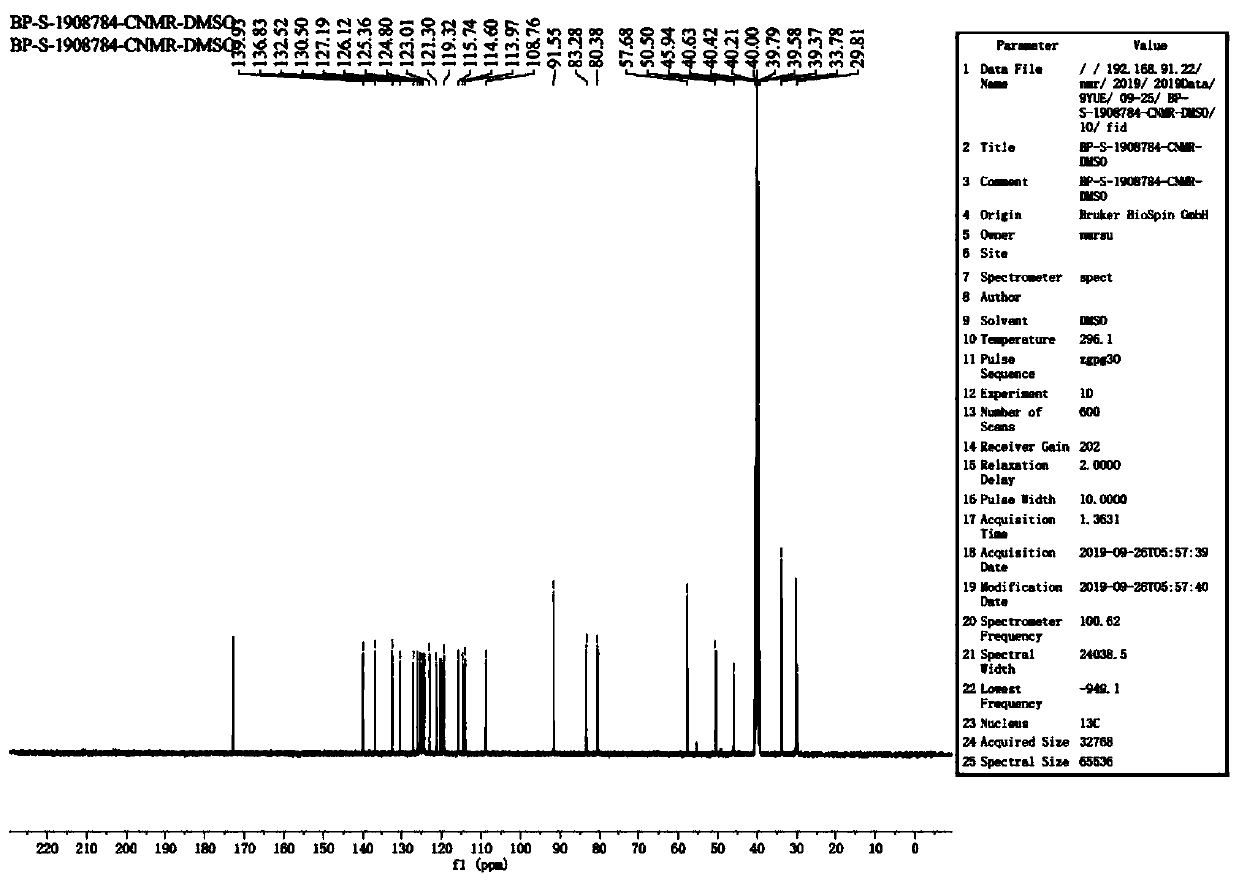

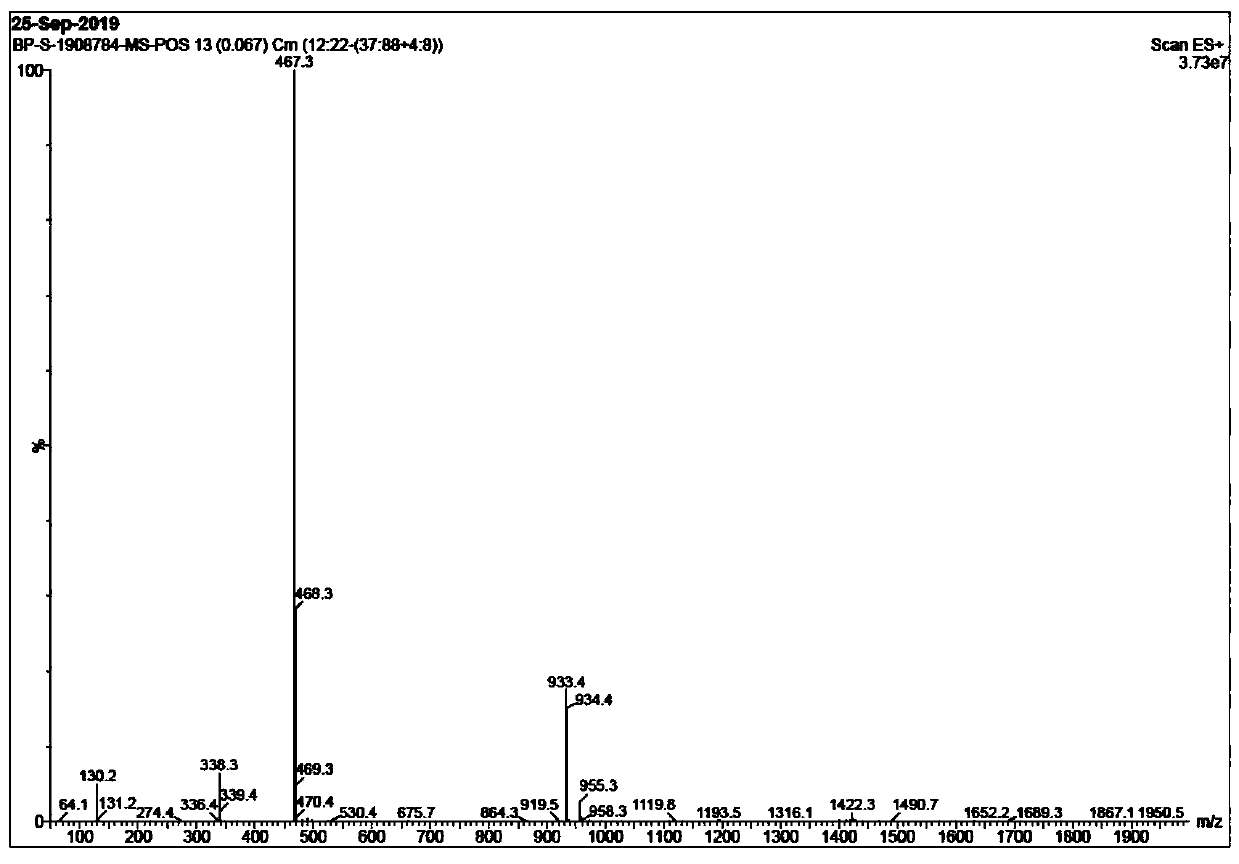

Image

Examples

Embodiment 1

[0036] (1) Add 3% perlite (according to the volume of the fermentation broth, Kg / L) to the staurosporine fermentation broth, stir for 30 ± 5min, plate and frame filter, the filtrate is discharged to the sewage treatment station, and the filter cake is blown with compressed air Dry for 2±0.5h, collect the fungus residue;

[0037] (2) extract bacterium residue with organic solvent 3 times, add the solvent of 4 times volume (L / Kg bacterium residue) each time, filter, merge filtrate;

[0038] (3) The filtrate is concentrated under reduced pressure at a certain temperature to 1 / 30 of the original volume, adding an equal volume of solvent, an equal volume of aqueous solution, and 1 / 3 volume of extraction aid, stirring for 30 ± 10 min, and standing for 60 ± 10 min. Separate the liquid, extract the aqueous phase with the original volume of solvent once more, combine the organic layers, add 5% (Kg / L) anhydrous sodium sulfate, stir and dry for 60±10min, and filter;

[0039] (4) Concent...

Embodiment 2

[0043] (1) Add 9Kg perlite to 300L fermented liquid containing staurosporine 451mg / L, stir for 30±5min, plate and frame filter, discharge the filtrate to the sewage treatment station, dry the filter cake with compressed air for 2±0.5h, Get 62Kg of fungus residue;

[0044] (2) Put the fungus residue into a 500L mixing tank, add 250L of absolute ethanol, stir for 5±1h, filter out the extract, keep the fungus residue in the tank, add absolute ethanol to extract twice, 250L each time, combine filtrate;

[0045] (3) Concentrate the filtrate under reduced pressure at 50±5°C to 25-30L, add 30L chloroform, 30L 2% ammonia water, 10L anhydrous methanol, stir for 30±10min, let stand for 60±10min, separate liquid, water phase Extract once more with 30L chloroform, combine the organic layers, add 3Kg anhydrous sodium sulfate, stir and dry for 60±10min, and filter;

[0046] (4) Concentrate the filtrate to 3L under reduced pressure at 35±5°C, add 6L of anhydrous methanol, stir at room temp...

Embodiment 3

[0050] (1) Add 9Kg perlite to 300L fermented liquid containing staurosporine 408mg / L, stir for 30±5min, plate and frame filter, discharge the filtrate to the sewage treatment station, dry the filter cake with compressed air for 2±0.5h, Get 65Kg of fungus residue;

[0051] (2) Put the fungus residue into a 500L stirring tank, add 250L of acetone, stir for 5±1h, filter out the extract, keep the fungus residue in the tank, add acetone to extract twice, each time 250L, and combine the filtrate;

[0052] (3) Concentrate the filtrate to 25-30L under reduced pressure at 50±5°C, add 30L dichloromethane, 30L 3% sodium carbonate, 10L anhydrous methanol, stir for 30±10min, let stand for 60±10min, separate liquid, water The phase was extracted once more with 30L dichloromethane, the organic layers were combined, 3Kg anhydrous sodium sulfate was added, stirred and dried for 60±10min, and filtered;

[0053] (4) Concentrate the filtrate to 3L under reduced pressure at 35±5°C, add 6L of acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com