Circulating overflow type electric assisted ozone water treatment equipment as well as method for treating water thereby

An ozonated water and over-flow technology, which is used in oxidized water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem that the reaction rate is limited by the effective area of the electrode, the treatment system is prone to dead ends, Increase the size of the reactor to achieve the effect of promoting the electrode interface reaction, improving the efficiency of the electrochemical reaction, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

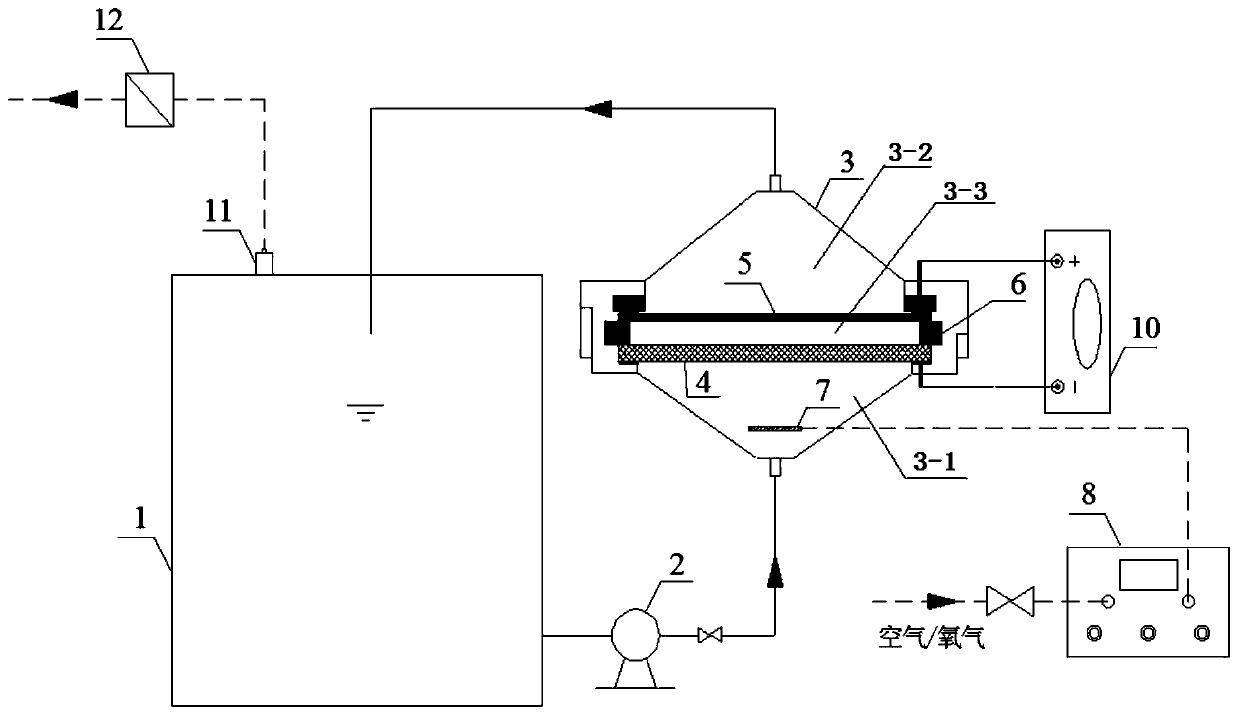

[0032] Circulating flow-type electro-assisted ozone water treatment equipment, see figure 1 , including a homogeneous reactor 1 and an electrochemical reaction device 3 connected to each other to form a circulation path, and an ozone generator 8; the electrochemical reaction device 3 is internally provided with parallel cathodes 4 and anodes that are all capable of permeating water and gas 5. Divide its internal space into a lower chamber 3-1 located below the cathode 4, an upper chamber 3-2 located above the anode 5, and an intermediate chamber 3-3 located between the two electrodes, and the two electrodes The edge is sealed with the inner wall of the electrochemical reaction device 3, the water inlet of the lower chamber 3-1 is connected with the water outlet of the homogeneous reactor 1, and the water outlet of the upper chamber 3-2 is connected with the outlet of the homogeneous reactor 1. The water inlet is connected, and the lower chamber 3-1 is provided with a gas dispe...

Embodiment 2

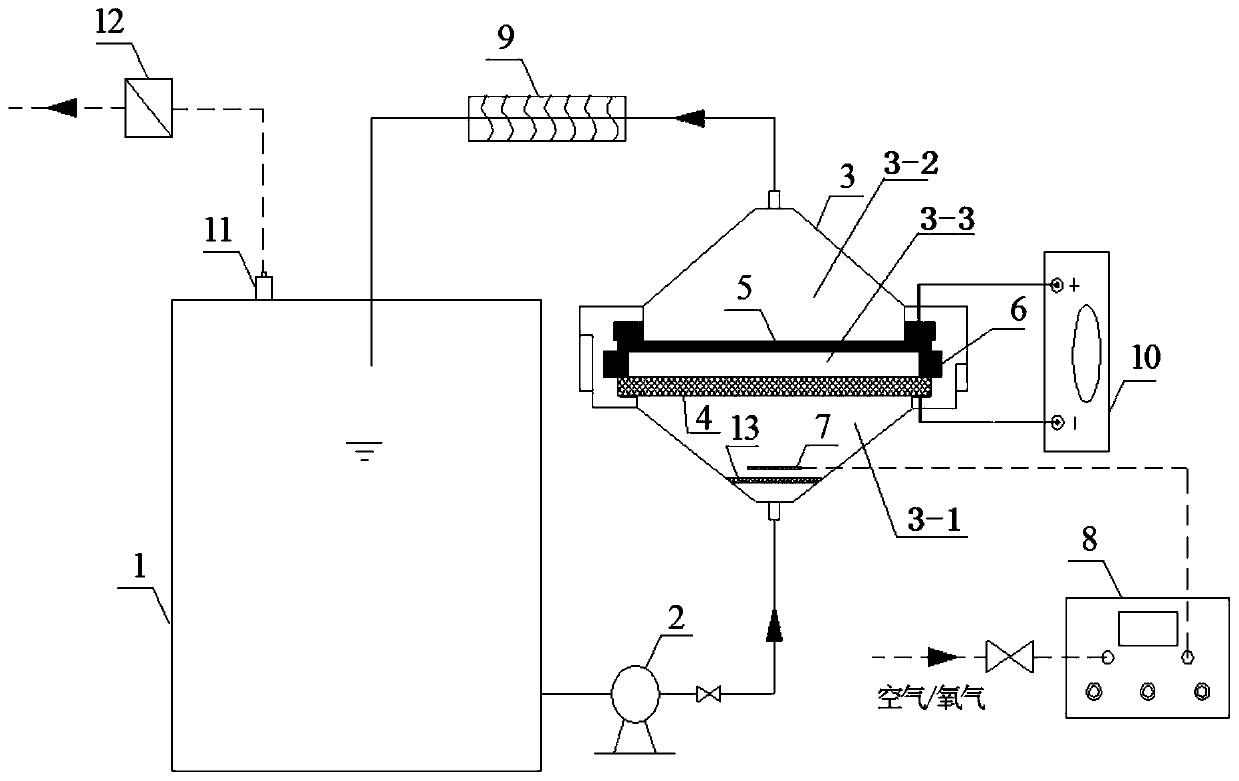

[0037] Circulating flow-type electro-assisted ozone water treatment equipment, see figure 2 , is basically the same as that of Embodiment 1, the only difference is that: a gas-liquid mixing device 9 and a water distributor 13 are also included. The water inlet / gas end of the tubular gas-liquid mixing device 9 is connected with the water outlet / gas end of the electrochemical reaction device 3; The water inlet and the gas end are connected; the water distributor 13 is placed in the lower chamber 3-1 of the electrochemical reaction device 3, below the gas dispersion device 7, so that the fluid energy entering the electrochemical reaction device 3 can be evenly distributed.

[0038] In the tubular gas-liquid mixing device 9, the gas-liquid mixture flowing out of the electrochemical reaction device 3 can be further mixed, so that the residual ozone gas can be fully absorbed and utilized, and the reaction system can be made uniform and the mass transfer of the reaction system can b...

Embodiment 3

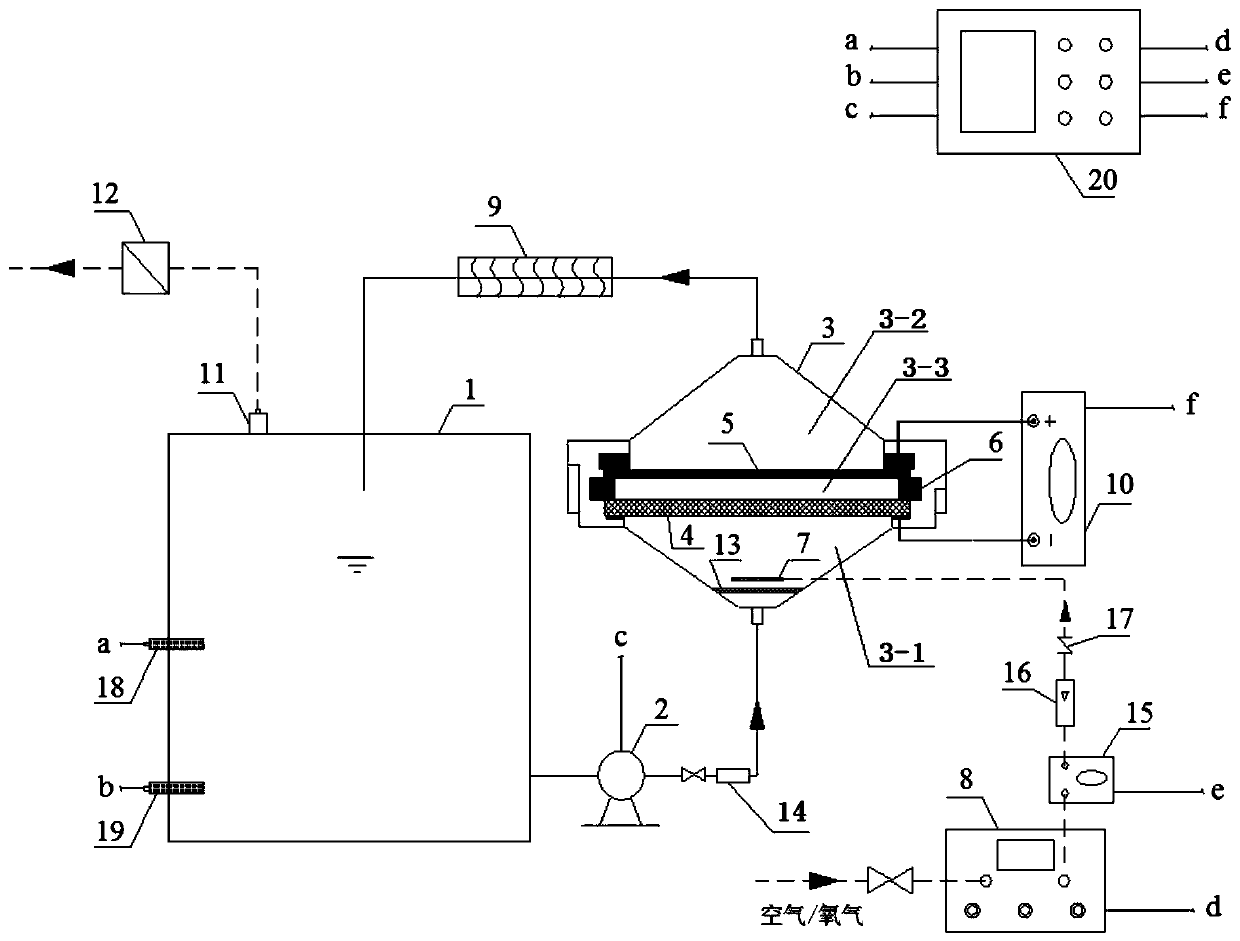

[0040] Circulating flow-type electro-assisted ozone water treatment equipment, see image 3 , is basically the same as Embodiment 2, the only difference is that it also includes a liquid flow meter 14, a gas phase ozone concentration monitor 15, a gas flow meter 16, a check valve 17, a liquid phase ozone concentration sensor 18, and a dissolved oxygen concentration sensor 19 , the automatic control unit 20. The liquid flowmeter 14 is placed after the water outlet of the water pump 2, before the electrochemical reaction device 3; the gas phase ozone concentration monitor 15, the gas flowmeter 16, and the check valve 17 are connected successively after the ozone generator 8; The liquid phase ozone concentration sensor 18 and the dissolved oxygen concentration sensor 19 are placed on the side wall of the homogeneous reactor 1 . The automatic control unit 20 can receive the signals of the connected components, and then output the control signals, so as to control the circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com